Meltblown composite production device formed by one-step molding

A kind of production equipment and melt-blown technology, which is applied in the field of multiple melt-blown filter materials forming composite production equipment, can solve the problems of time-consuming, large equipment investment, and affecting the use effect, so as to ensure the needs of automatic production, ensure the mixing of materials, reduce the The effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

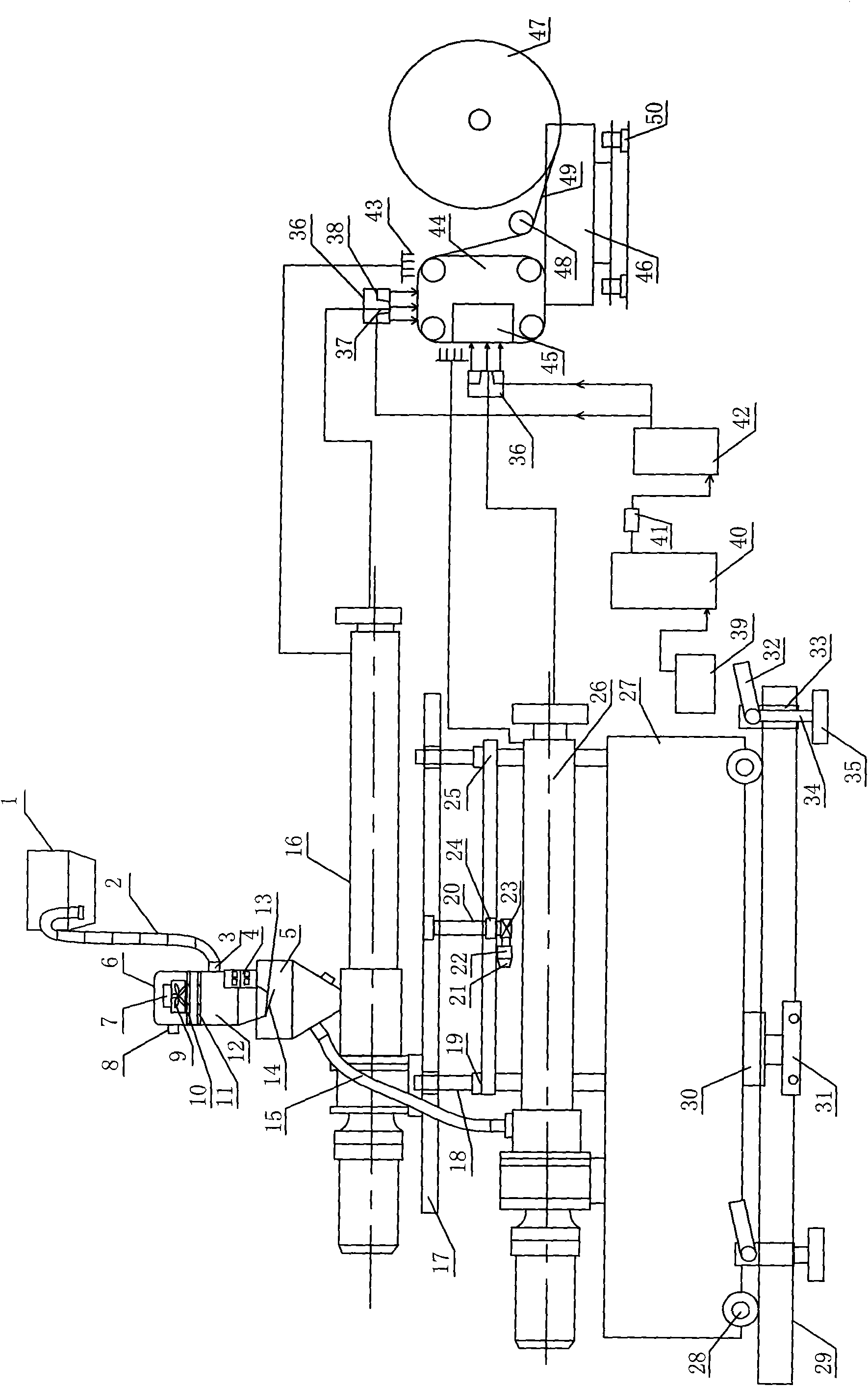

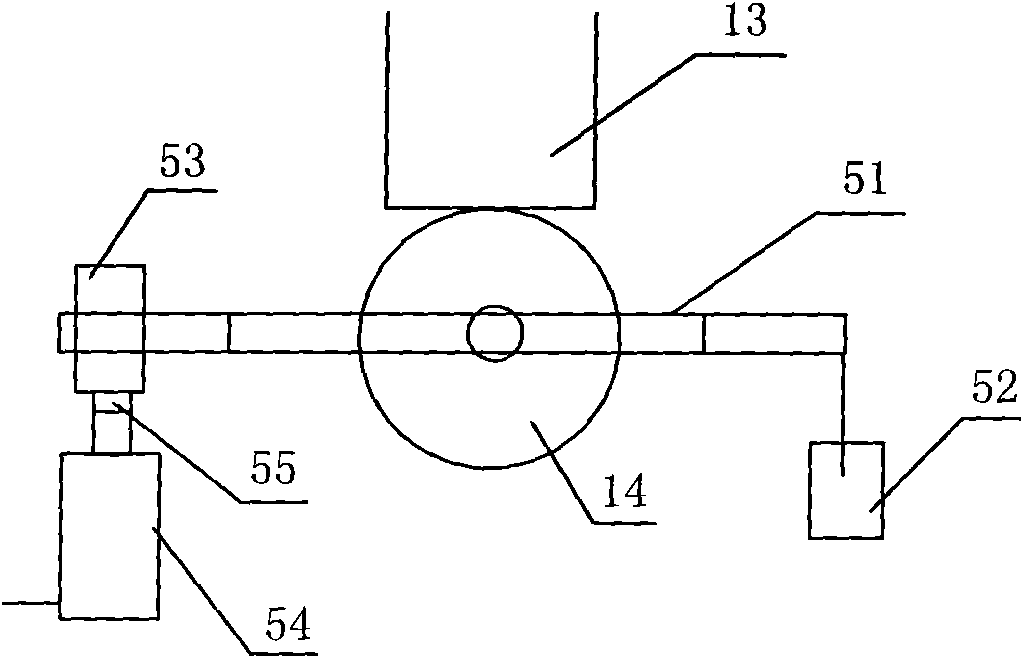

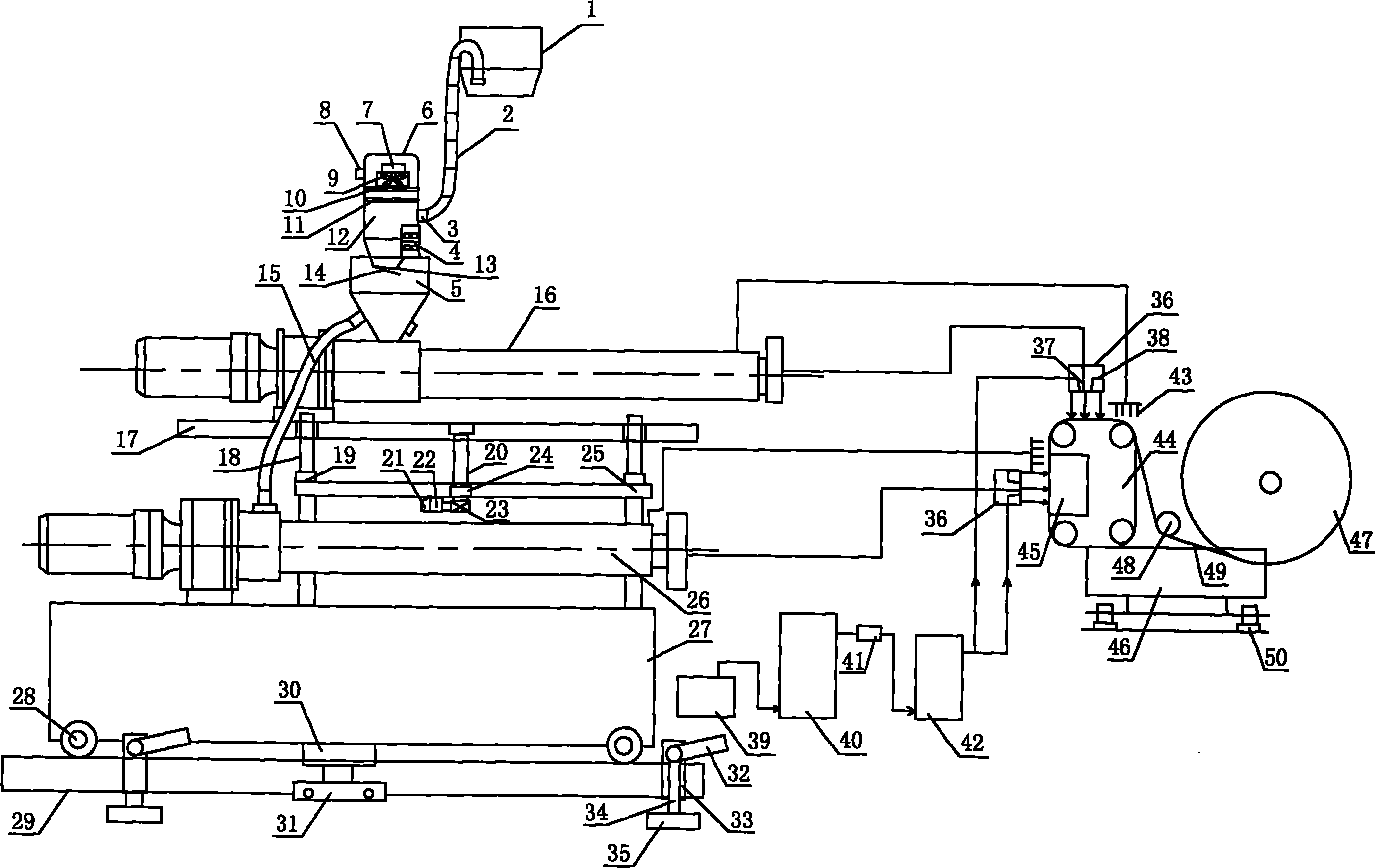

[0028] Refer to attached figure 1 , 2 , the one-time molding melt-blown composite production equipment includes a frame 17, an automatic feeding device, a screw extruder 16, 26, a nozzle 36, an air supply device, a receiving net 44, an air suction device 45, and a reciprocating car 46 that can move laterally. Cloth pressing roller 48, balance tension take-up roller 47, electret frame 43 and screw extruder automatic lifting device.

[0029] The automatic feeding device comprises a silo 1, a feeding pipe 2, a feeding cylinder 12, a suction fan, a filter screen 11 and a hopper 5. The hopper 5 is installed on the upper part of one of the screw extruders 16 and communicates with the material mixing chamber of the screw extruder. The upper part of the hopper 5 is equipped with a feeding cylinder 12, and the upper part of the feeding cylinder 12 is equipped with a suction fan. The suction fan has a suction motor 7. The suction motor 7 is equipped with a fan 9, the top of the suctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com