Laser grooving and scribing system and laser grooving and scribing method for solar panel

A solar cell panel and laser scribing technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as damage and lower photoelectric conversion efficiency of solar cells, so as to improve the accuracy of scribing lines, reduce processing costs, The effect of increasing the preheating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

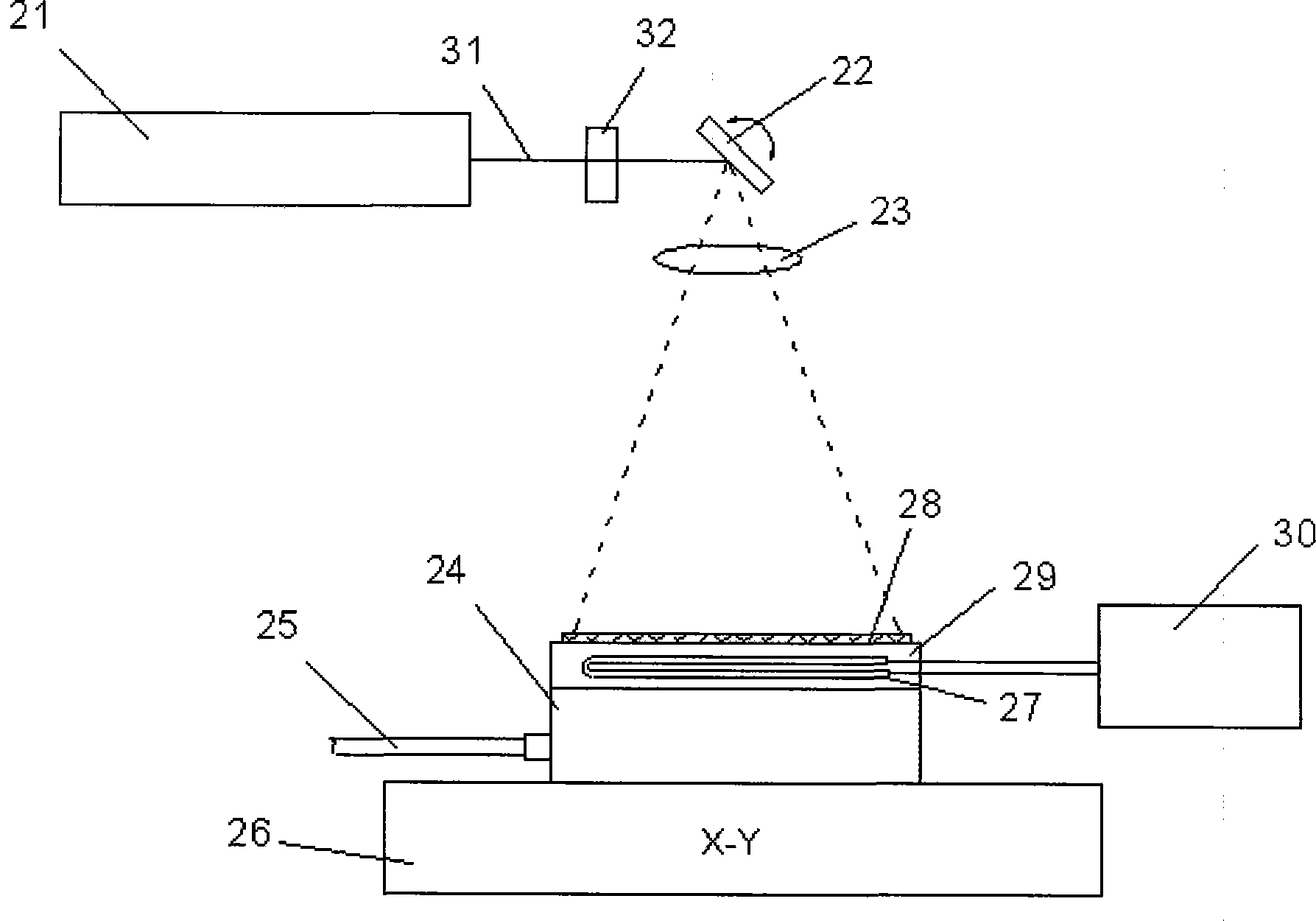

[0028] Such as figure 2 Shown: the present invention comprises laser 21, laser scanner 22, lens 23, stage 24, vacuum tube 25, mobile platform 26, electric heater 27, battery plate 28, heating device 29, temperature controller 30, laser beam 31 And the beam spreading device 32.

[0029] Such as figure 2 As shown: the laser 21 is used to generate a laser light source, and the output end of the laser 21 generates a laser beam 31, and the laser beam 31 enters the laser scanner 22 after passing through the beam diffusion device 32; the laser scanner 22 is located at the beam diffusion The device 32 corresponds to the other side connected to the laser 21 . The laser scanner 22 scans the battery board 28 on the stage 24 according to the set pattern, so as to obtain the set shape on the battery board 28 . A stage 24 is provided below the laser scanner 22, and a lens 23 is arranged between the stage 24 and the laser scanner 22, and the lens 23 is used to keep the focus of the lase...

Embodiment 2

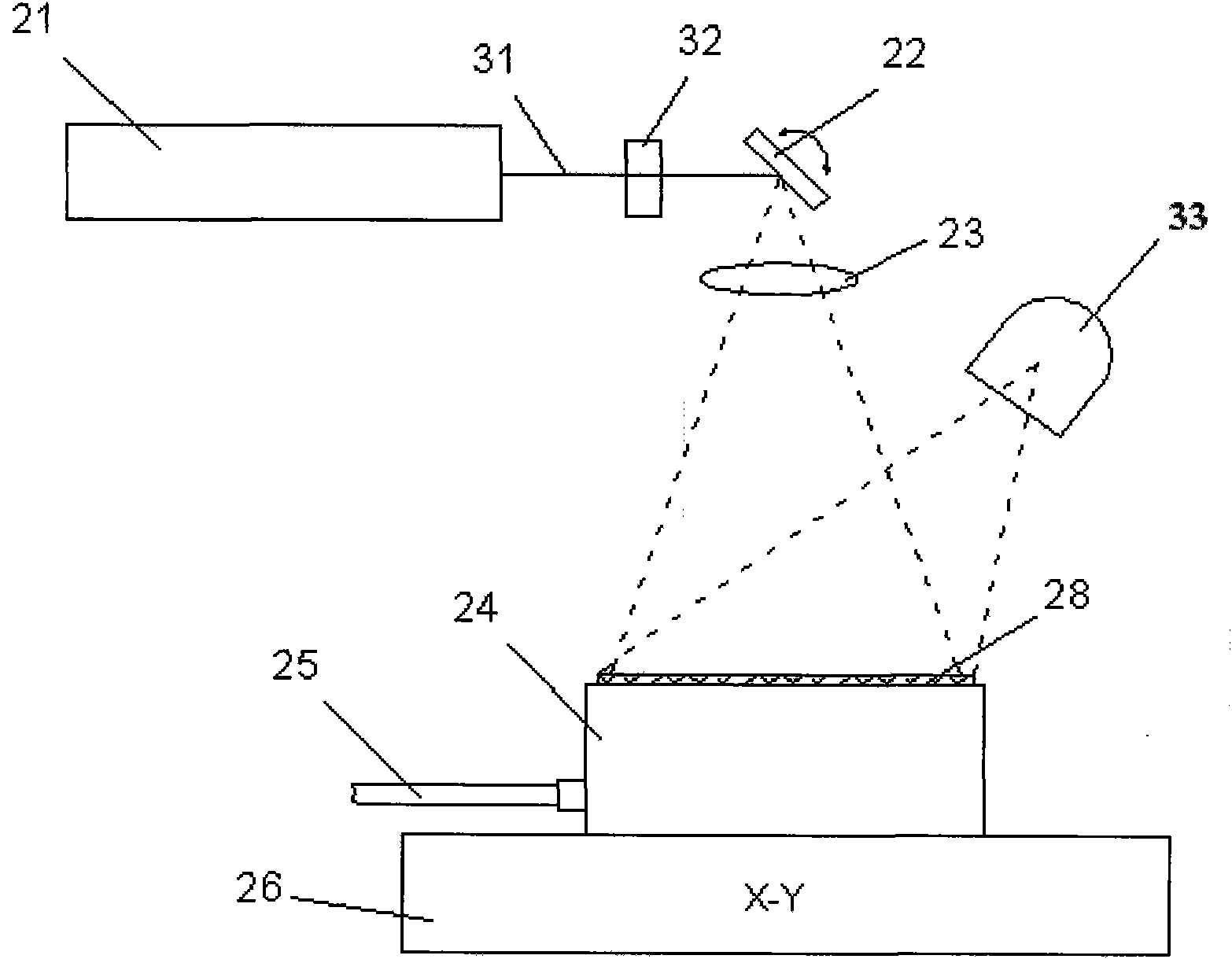

[0041] Such as image 3 Shown: the present invention includes a laser 21, a laser scanner 22, a lens 23, an object stage 24, a vacuum tube 25, a moving stage 26, a battery board 28, a laser beam 31, a beam diffusing device 32 and an infrared heater 33.

[0042] Such as image 3 As shown: the laser beam 31 generated by the laser 21 is input to the laser scanner 22 through the beam spreading device 32 , and the lens 23 and the stage 24 are arranged below the laser scanner 22 . The stage 24 is provided with a number of positioning holes and positioning grooves, and the positioning holes and positioning grooves are all connected with the vacuum tube 25 on the stage 24 . Correspondingly, the other end of the stage 24 adjacent to the laser 22 is provided with a fixedly connected mobile platform 26 . An infrared heater 33 is arranged above the stage 24, and the infrared heater 33 is a quartz lamp tube or a ceramic heater. The battery board 28 is placed on the end of the stage 24 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com