Preheating and heat preservation control method of zero-cold-water gas water heater

A technology of a gas water heater and a control method, which is applied to fluid heaters, lighting and heating equipment, etc., and can solve problems such as large heat loss, long preheating time, and slow temperature rise of return water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

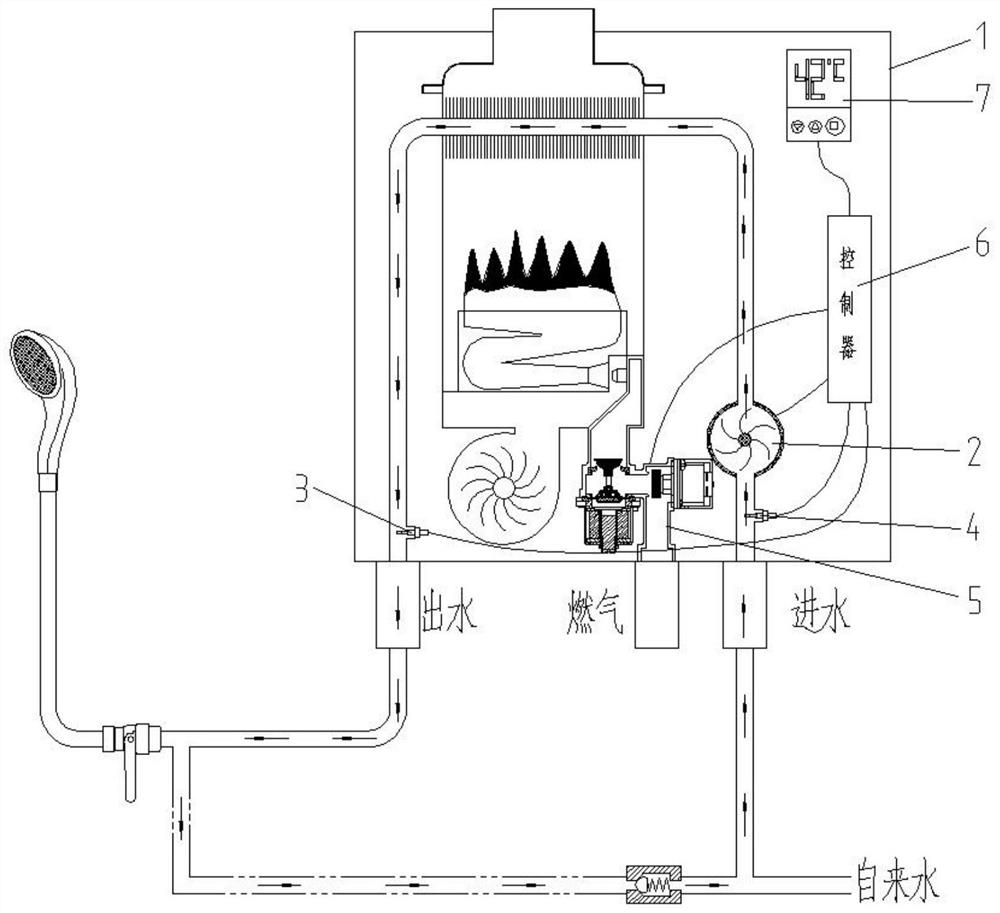

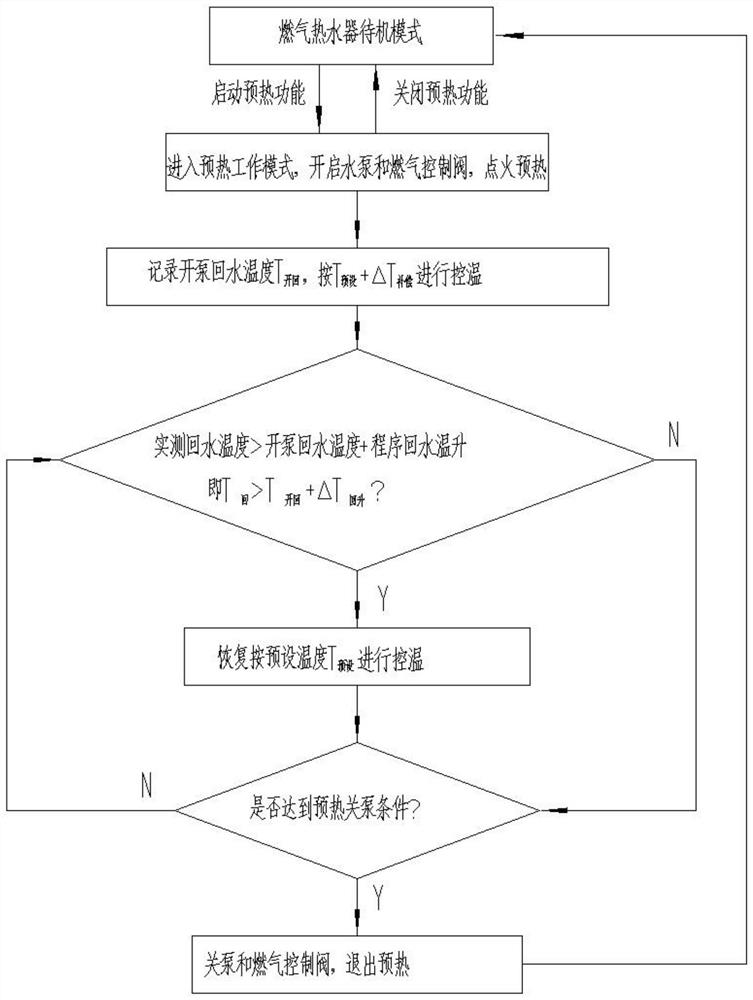

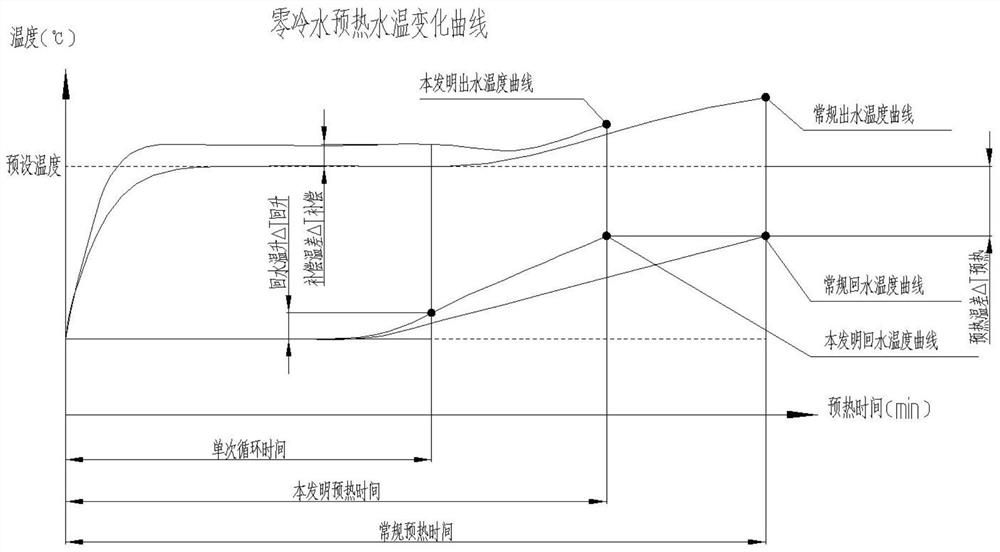

[0025] Embodiment one: if figure 1 , figure 2 with image 3 As shown, this embodiment provides a preheating and heat preservation control method for a zero-cold water gas water heater, wherein the gas water heater includes a water heater body 1, a water pump 2, an outlet water temperature probe 3, a return water temperature probe 4, a gas control valve 5, and a controller 6 And the operation display 7, the main water circuit 10 of the water heater body 1 includes a water inlet pipeline, a water outlet pipeline and a water return pipeline, and the water inlet pipeline, the water outlet pipeline and the water return pipeline are connected in sequence to form a circulation pipeline for circulating preheating, and the water pump 2 is installed on the main waterway 10 of the water heater body 1, the outlet water temperature probe 3 is installed on the water outlet end of the main waterway 10 of the water heater body 1 for real-time monitoring of the outlet water temperature, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com