Plasma cleaning apparatus for a semiconductor panel with cleaning chambers

A technology of plasma and cleaning equipment, which is applied in semiconductor/solid-state device manufacturing, cleaning methods and appliances, electrical components, etc., can solve the problems of low cleaning efficiency and productivity, and cannot clean the process, and achieve the effect of improving work ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Reference will now be made in detail to the detailed description of the invention, examples of which are illustrated in the accompanying drawings. In accordance with the principle that the inventor can properly define terms and concepts to best describe the present invention, terms and words in the specification and claims of the present invention need to be interpreted such that their meanings and concepts conform to the technical concept of the present invention.

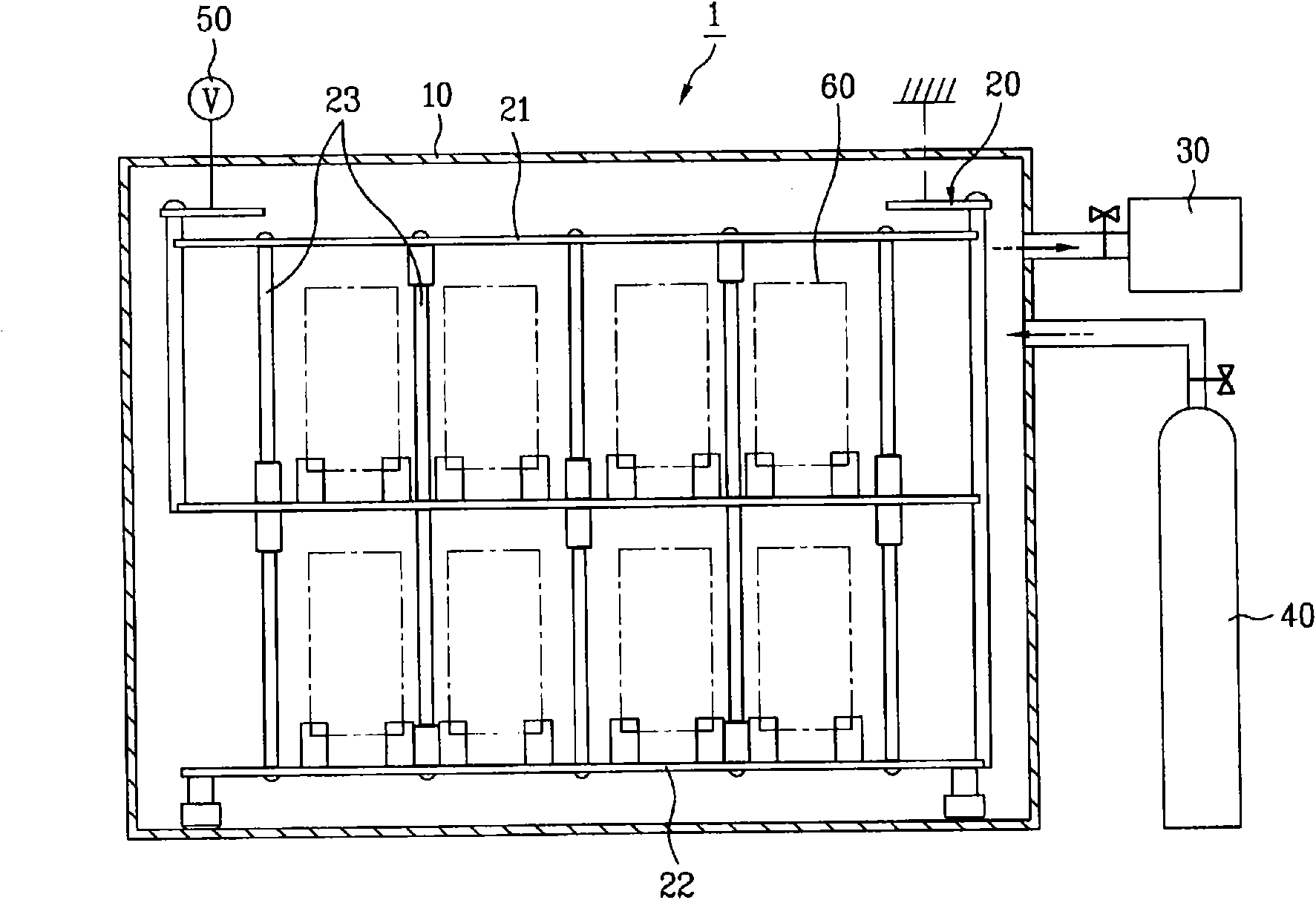

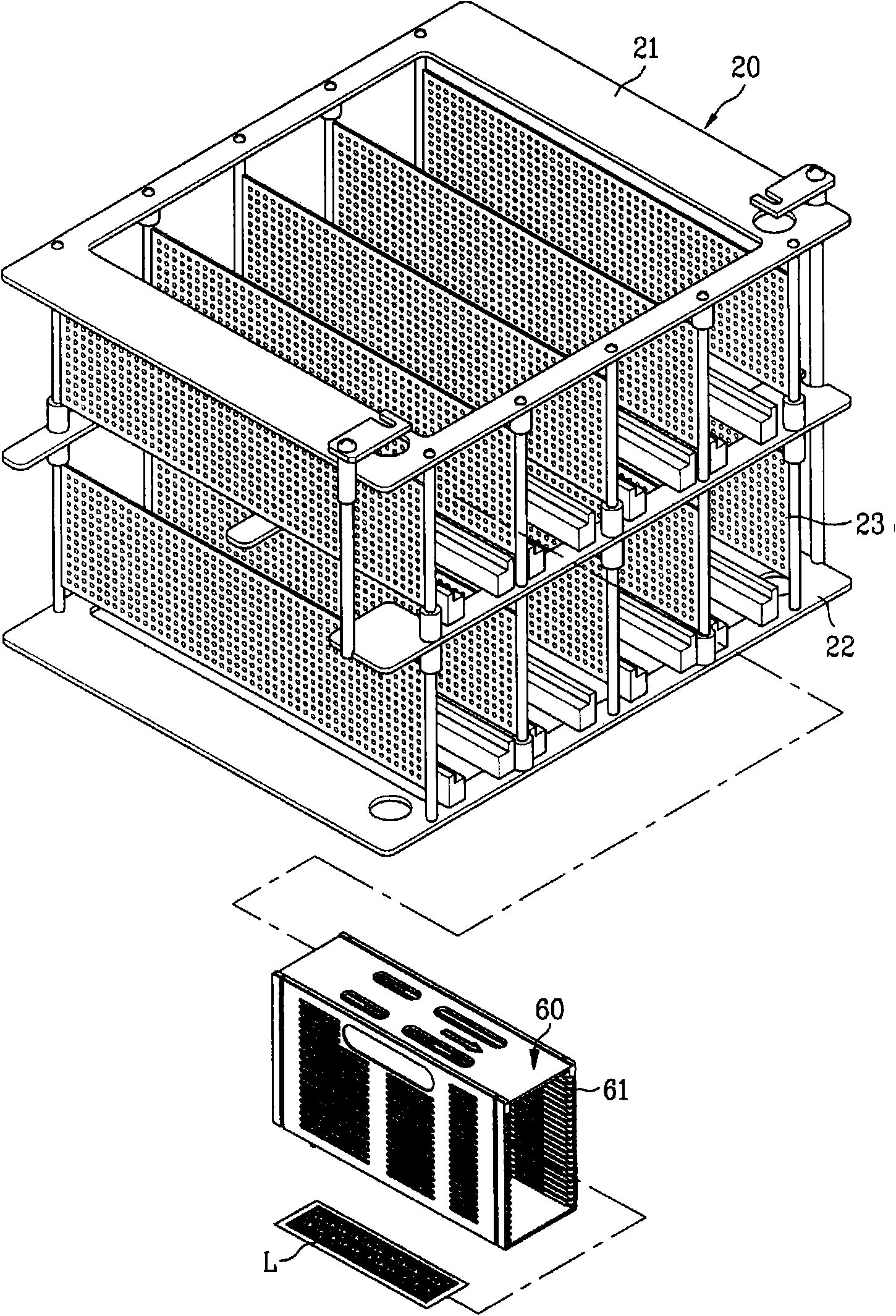

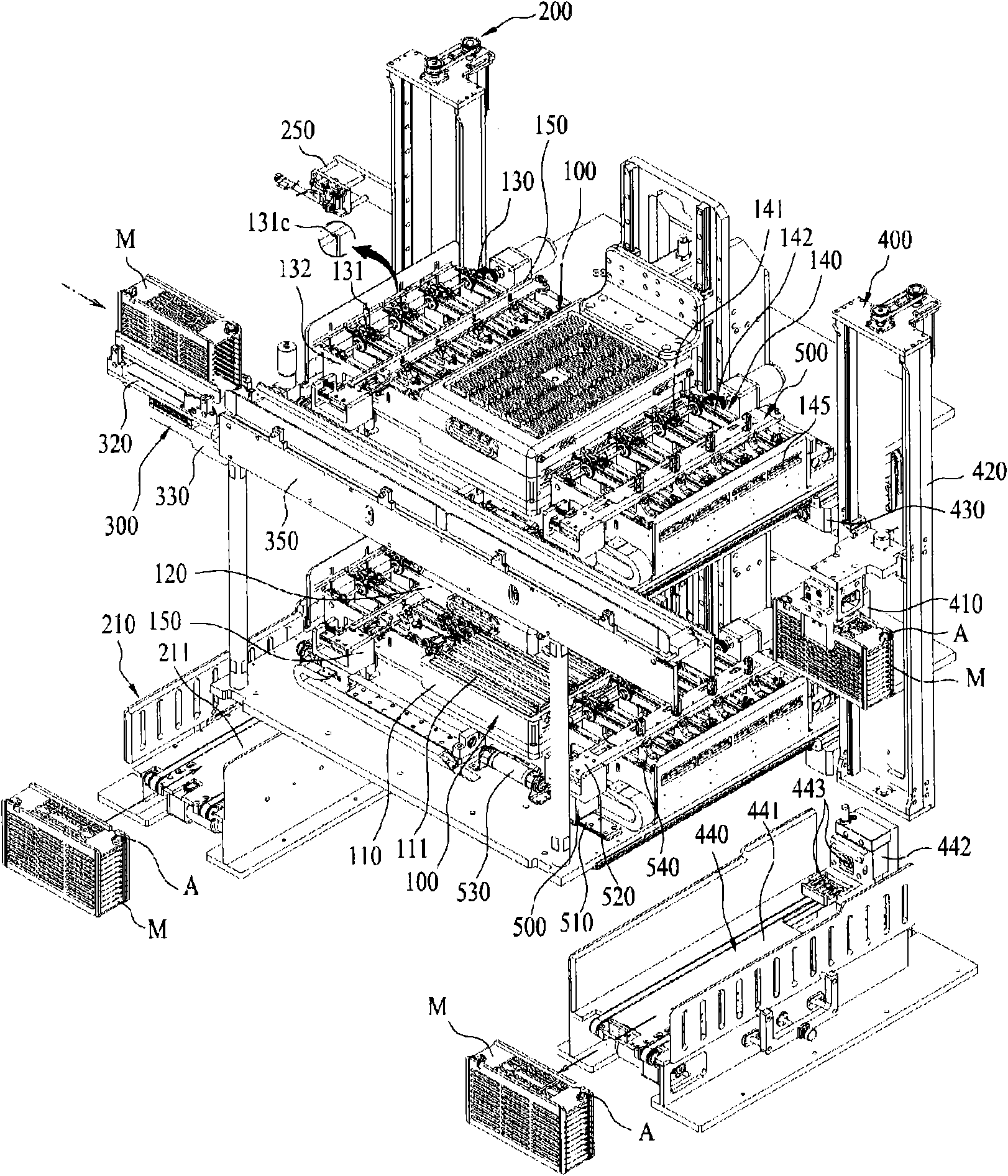

[0031] refer to image 3 and Figure 4 , the semiconductor plasma cleaning apparatus with a plurality of cleaning chambers of the present invention includes: a plurality of upright cleaning chambers 100; an unloading unit 200 for successively conveying boxes with cleaning objects loaded thereon; a first pusher 250 , is installed to the unloading unit 200 to discharge the cleaning object loaded in the box toward the cleaning chamber 100; the rotatable transfer unit 300 is used to receive the empty box in wh...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap