Drafting device capable of realizing mixed feeding of different raw materials on spinning frame

A drafting device and spinning frame technology, applied in the field of textile processing, can solve problems such as feasibility limitation and difficulty in spinning processing, and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

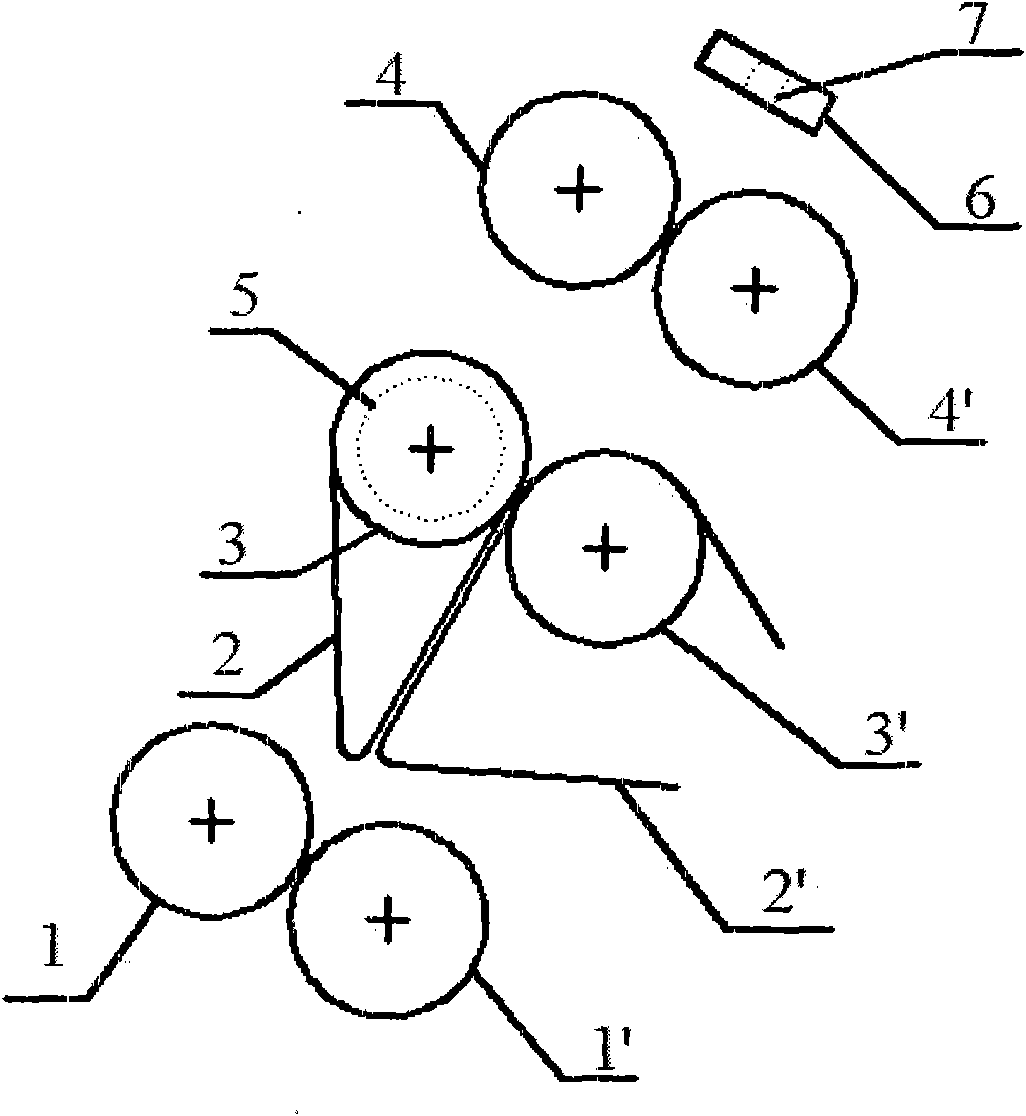

Method used

Image

Examples

Embodiment 1

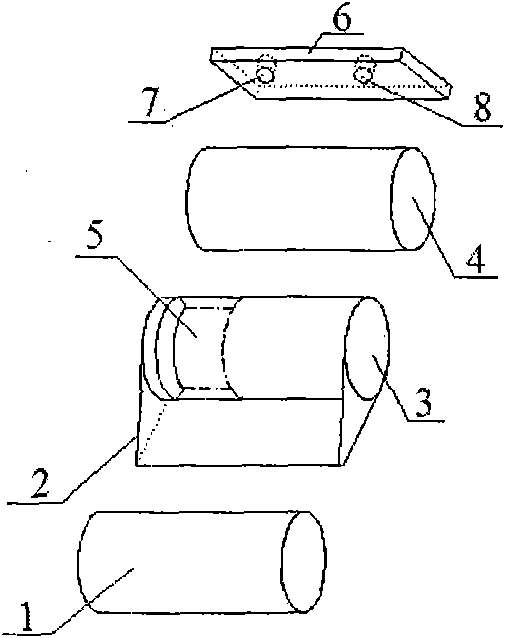

[0029] See figure 2 Open a positioning ring groove 5 with a width of 12 mm and a depth of 3 mm in the center of one side of the middle top roller 3 of the spinning frame, and a positioning yarn feeding hole 7 with a diameter of 5 mm and a diameter of 5 mm on the positioning yarn feeding device 6. The yarn feeding hole 8 of 5mm locates the yarn feeding hole 7 and the yarn feeding hole 8 on the same horizontal line. The axis of the positioning yarn feeding hole 7 is collinear with the center line of the positioning annular groove 5, and the yarn feeding hole 8 is positioned at the side of the positioning yarn feeding hole 7. Set the center distance between front roller 1' and rear roller 4' as 140mm, and set the center distance between front roller 1' and middle roller 3' as 45mm. The above-mentioned structure is suitable for drafting of wool fiber and cotton fiber blended yarn.

[0030] Two wool staple fiber rovings and cotton staple fiber rovings (wherein the main body leng...

Embodiment 2

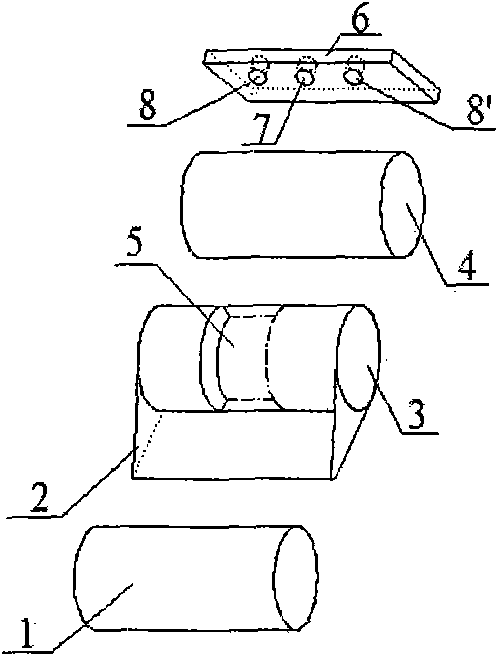

[0032] See image 3 Open a positioning annular groove 5 with a width of 10 mm and a depth of 3.5 mm in the middle of the middle top roller 3 of the spinning frame, and a positioning yarn feeding hole 7, a yarn feeding hole 8 and a yarn feeding hole on the positioning yarn feeding device 6 8', positioning the yarn feeding hole 7, the yarn feeding hole 8 and the yarn feeding hole 8' on the same horizontal line, and their apertures are 5mm. The axis of the positioning yarn feeding hole 7 is collinear with the center line of the positioning annular groove 5, and the yarn feeding hole 8 and the yarn feeding hole 8 ' are positioned at both sides of the positioning yarn feeding hole 7 respectively. Set the center distance between front roller 1' and rear roller 4' to be 145mm, and set the center distance between front roller 1' and middle roller 3' to be 50mm. The above structure is suitable for drafting of cashmere, viscose and polyester staple fiber blended yarns.

[0033] A bar ...

Embodiment 3

[0035] See Figure 4 In the middle of both sides of the middle top roller 3 of the spinning frame, a positioning annular groove 5 and a positioning annular groove 5' with a width of 8mm and a depth of 4mm are opened respectively, and two positioning yarn feeding holes 7 are opened on the positioning yarn feeding device 6. With 7 ' and a yarn feeding hole 8, positioning yarn feeding hole 7 and 7 ' and yarn feeding hole 8 are on the same horizontal line, and their apertures are 5mm. The axis of positioning yarn feeding hole 7 and positioning yarn feeding hole 7' is collinear with the midline of positioning annular groove 5 and 5' respectively, and yarn feeding hole 8 is positioned in the middle of positioning yarn feeding hole 7 and positioning yarn feeding hole 7'. Set the center distance between front roller 1' and rear roller 4' as 143mm, and set the center distance between front roller 1' and middle roller 3' as 42mm. The above-mentioned structure is suitable for drafting o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com