Method for producing gas phase heavy phosphorus-doped float zone silicon single crystal

A production method, zone melting silicon technology, applied in the production field of gas-phase heavily phosphorus-doped zone melting silicon single crystal, can solve problems such as failure to crystallize, copper coil ignition, blockage of doped pipes, etc., and achieve uniform axial resistivity , Solve the effect of coil ignition and low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to understand the present invention more clearly, describe the present invention in detail in conjunction with accompanying drawing and embodiment:

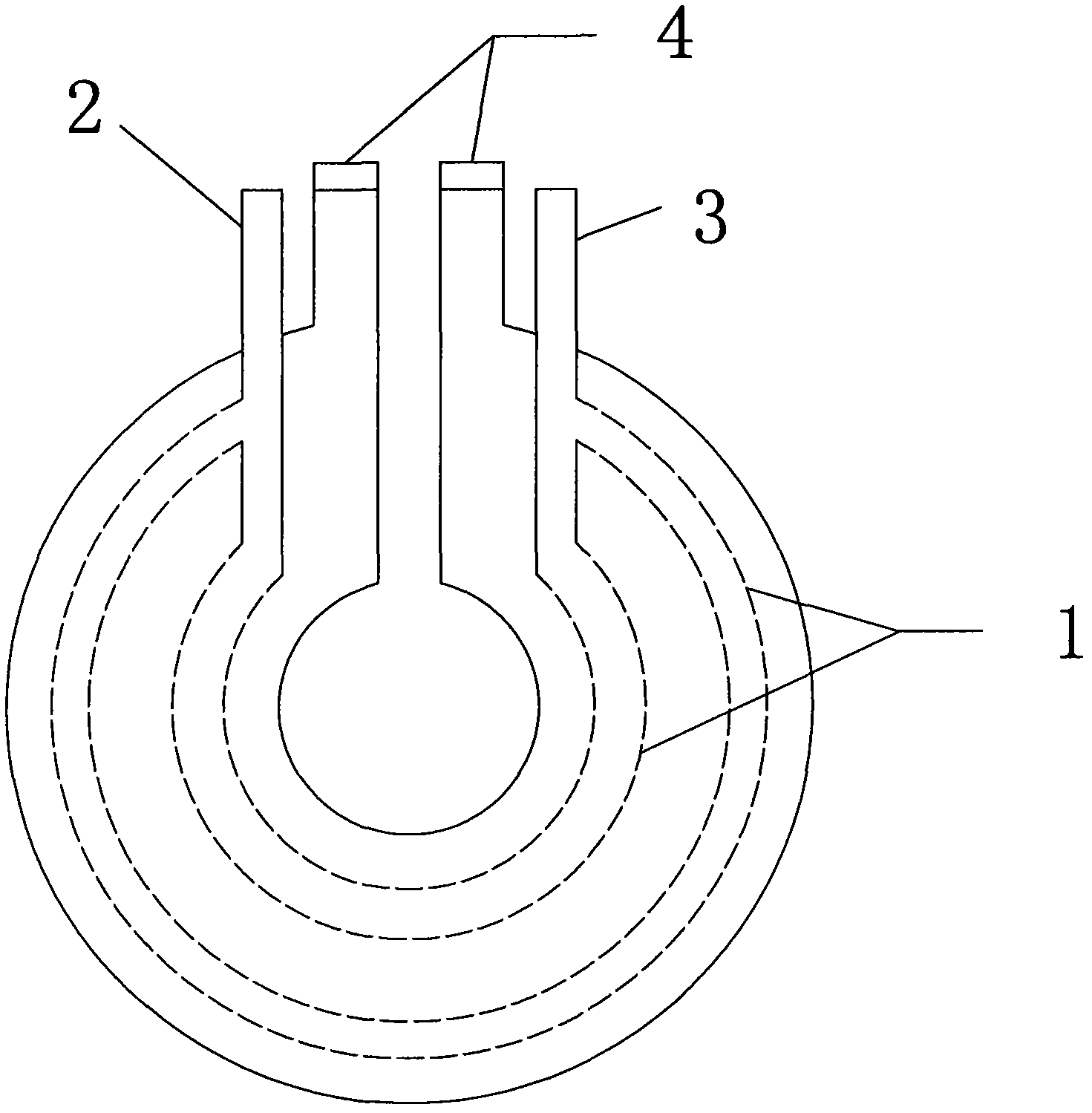

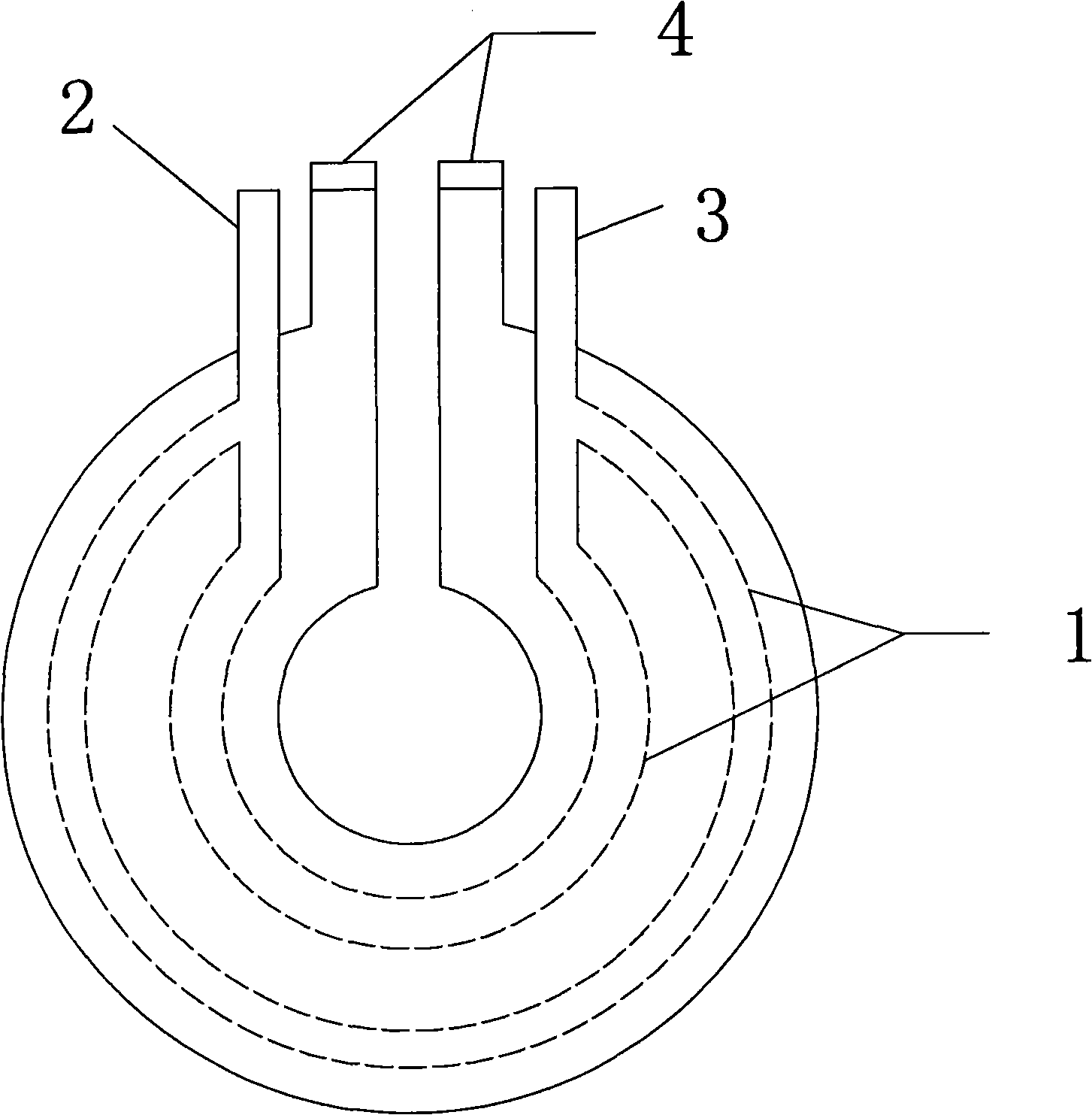

[0023] Such as figure 1 The electromagnetic copper coil with dual-water circuit water cooling shown includes dual-water circuit 1, dual-water circuit inlet pipe 2, dual-water circuit outlet pipe 3, and power supply positive and negative terminals 4; the electromagnetic copper coil with dual-water circuit water cooling is adopted. During the normal crystal pulling process, The temperature of the coil can be controlled between 10-20°C to effectively reduce the temperature, which effectively avoids the problem of chemical reaction between phosphorus and copper coil at high temperature and damage to the coil, which leads to the failure of normal crystal pulling.

[0024] Specific implementation cases are given below to further illustrate how the present invention is realized.

[0025] 1. The main equipment and raw ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com