Mobile wire induction heating controller

A technology of induction heating and controller, applied in the direction of induction heating control, induction heating, induction heating device, etc., can solve the problems of low heating wire temperature, system control precision change, inconvenient adjustment, etc., and achieve stable quality of processed products , high temperature control accuracy, and convenient parameter setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the embodiments and drawings:

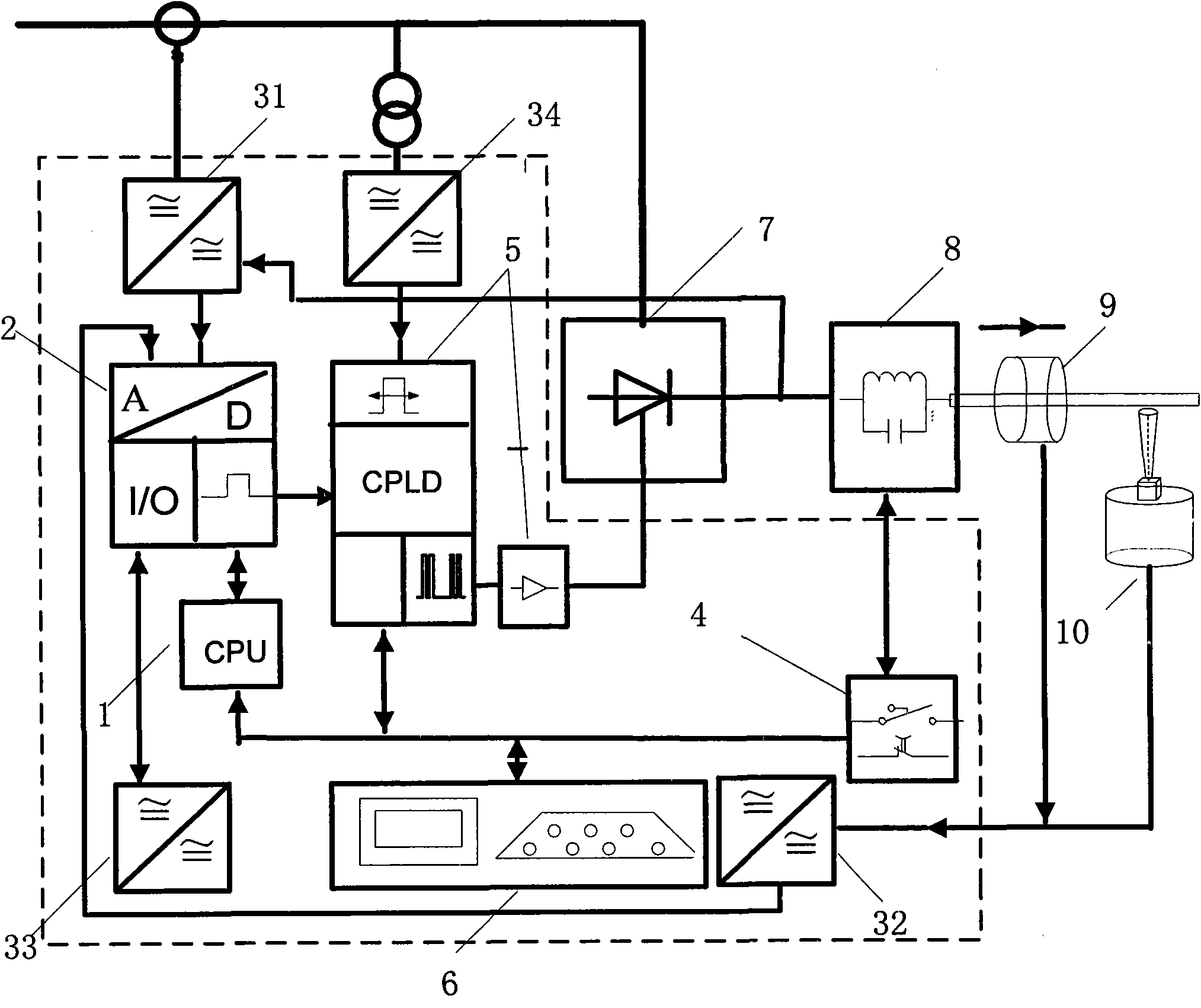

[0025] The mobile wire induction heating controller (referred to as the controller, see figure 1 ), characterized in that the controller adopts a fully digital modular design, including CPU system control module 1 (referred to as CPU module), data acquisition module 2, data adaptation module 3, start control module 4, digital pulse forming module 5 and human Machine dialogue module 6, the data includes analog quantity and switch quantity.

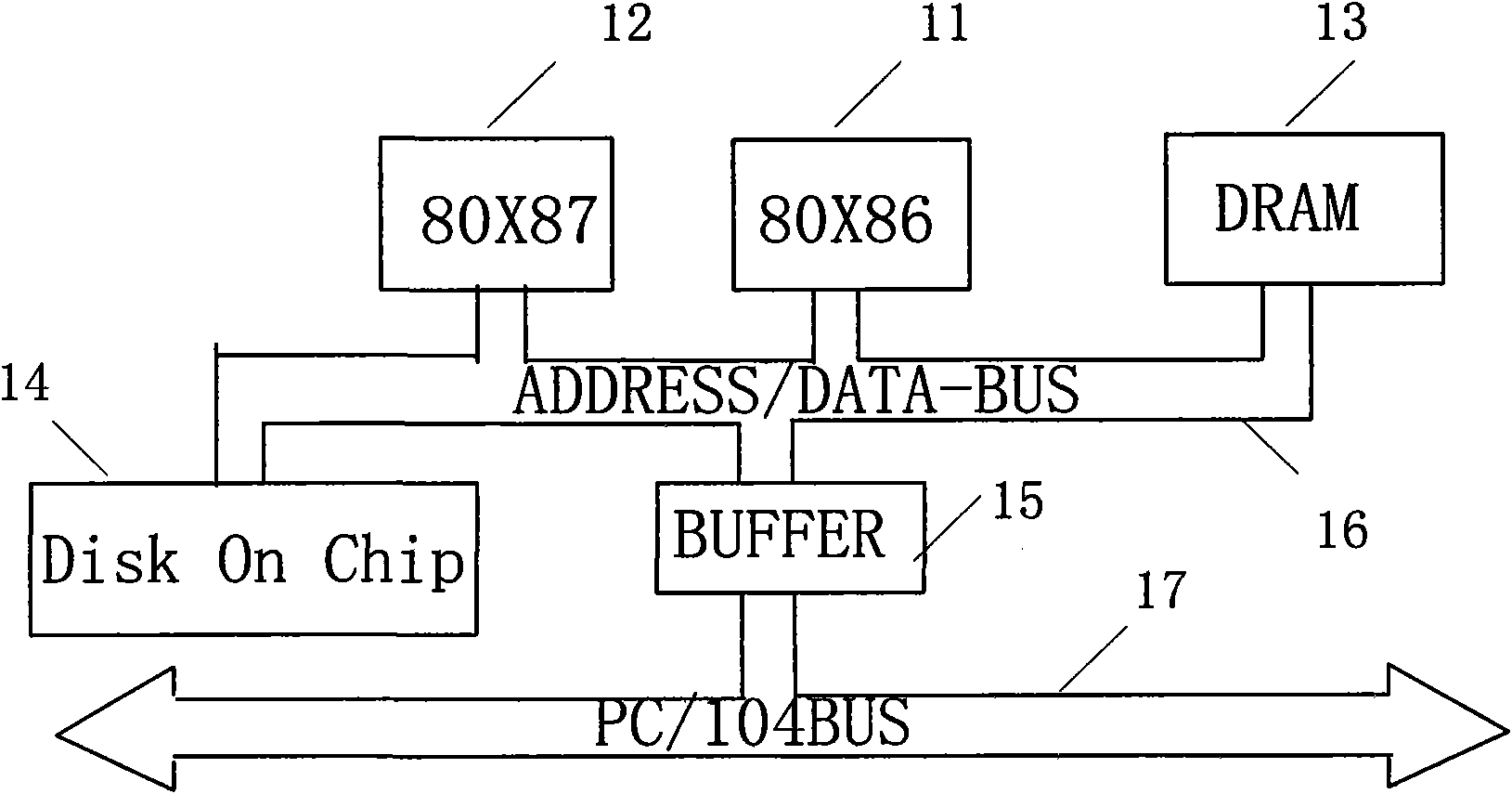

[0026] The CPU system control module 1 (see figure 2 ) It is composed of INTEL80X86 processor 11, INTEL80X87 floating point or data coprocessor 12, DISKONCHIP electronic disk 14 and DRAM13 dynamic memory. The composition structure complies with PC104 specifications. They complete the data exchange connection through the internal data bus and the address bus ADDRESS / DATA-BUS16, and connect to the external bus PC104BUS17 through the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com