Drilling tool technology procedure parameter adjustment test device controller and control method

A technology of parameter adjustment and test equipment, applied in the direction of comprehensive factory control, electrical program control, comprehensive factory control, etc., can solve problems such as no consistent conclusions, great influence of drilling tool temperature rise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0106] The present invention will be further described below in conjunction with the accompanying drawings.

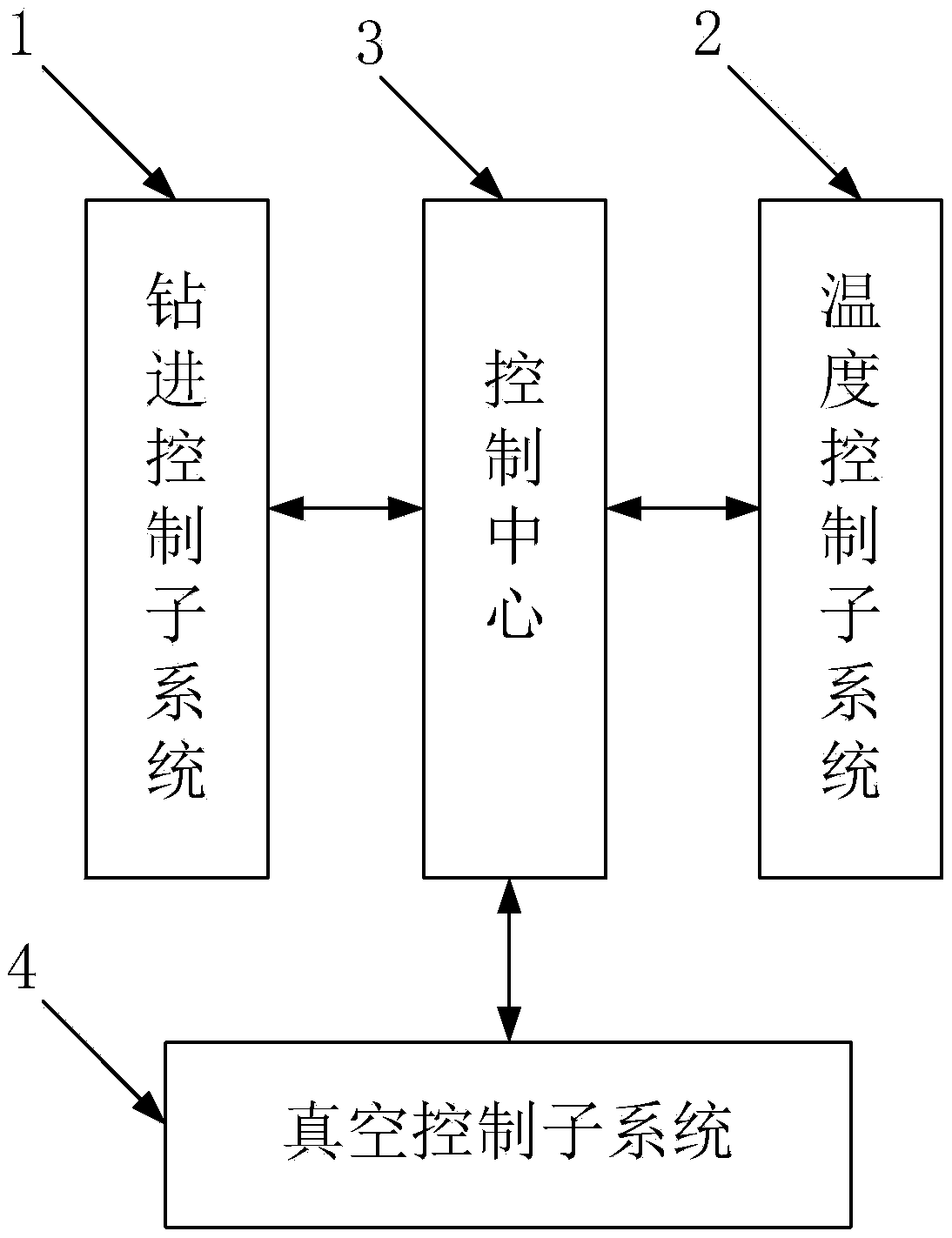

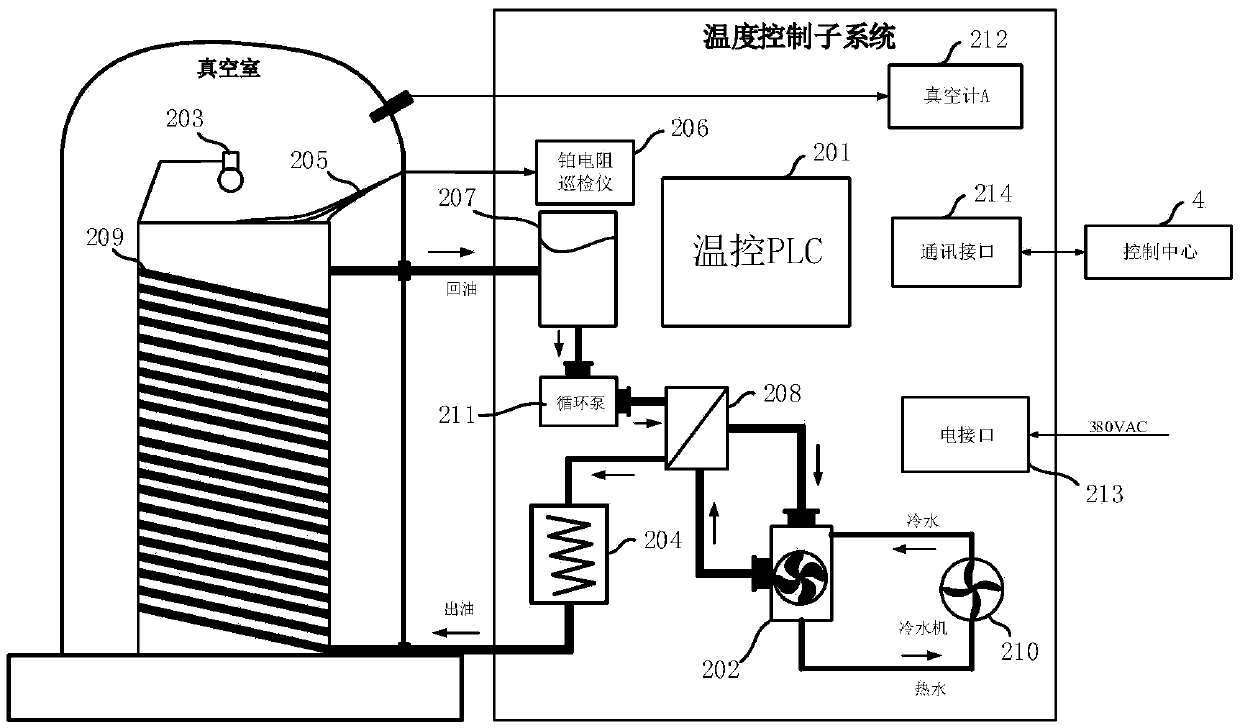

[0107] The controller of the drilling tool process specification parameter adjustment test device of the present invention includes a total of four parts: the drilling control subsystem, the temperature control subsystem, the vacuum control subsystem and the control center, such as figure 1 shown.

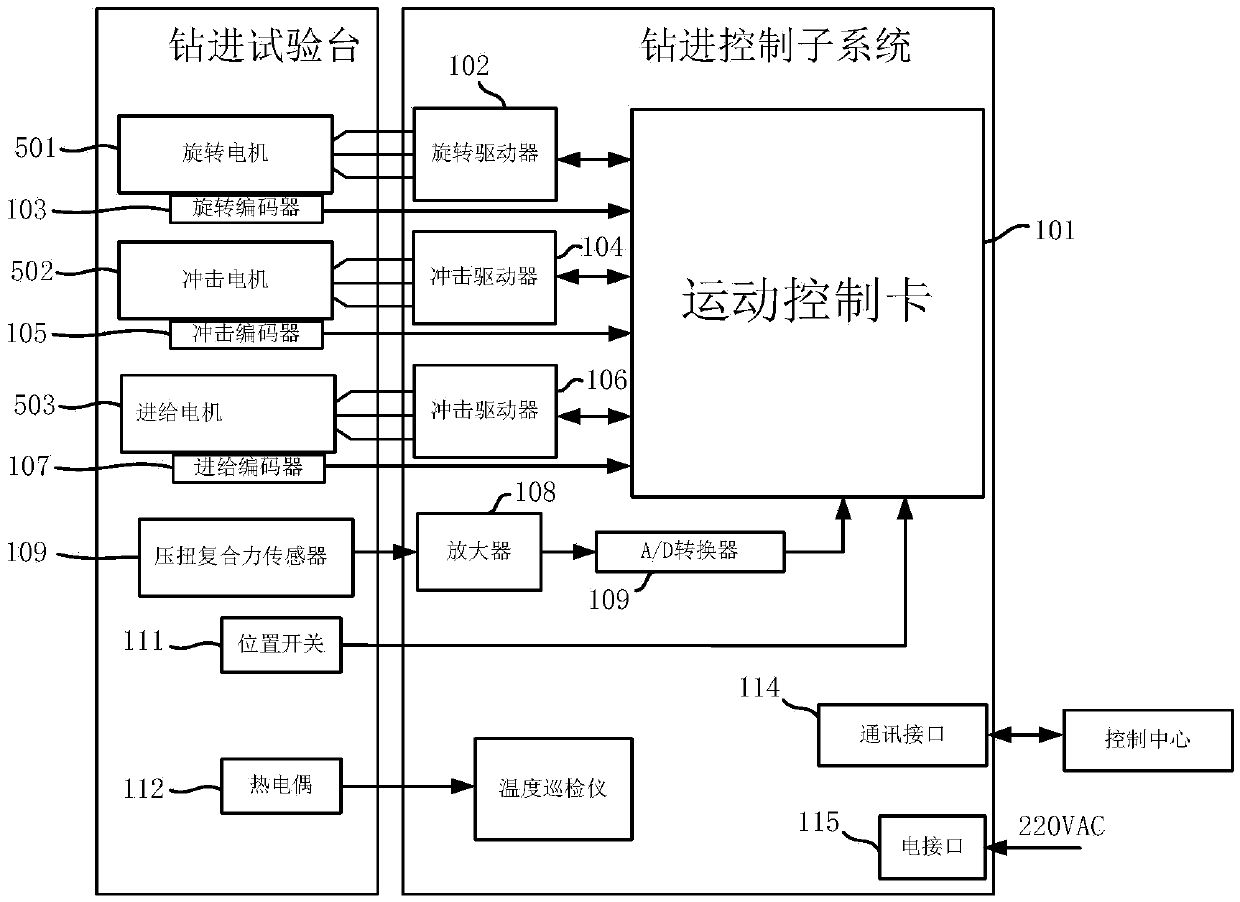

[0108] The drilling control subsystem is used to realize the drilling control of the drilling mechanism, including a motion control card, a rotary driver, a rotary encoder, an impact driver, an impact encoder, a feed driver, a feed encoder, an amplifier, an A / D converter, compression torsion compound force sensor, position switch, thermocouple, temperature inspection instrument, communication interface of drilling control subsystem, electrical interface of drilling control subsystem, such as figure 2 shown. Among them, the motion control card is the control core of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com