Carrying robot for coal mine rescue

A technology for robots and robot bodies, applied in brakes, buffers, mining devices, etc., can solve the problems of deterministic unevenness of track lines, aggravate the interaction force between wheels and rails, and affect the motion performance of robots, and achieve high practical value. The effect of strong athletic ability and fast moving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

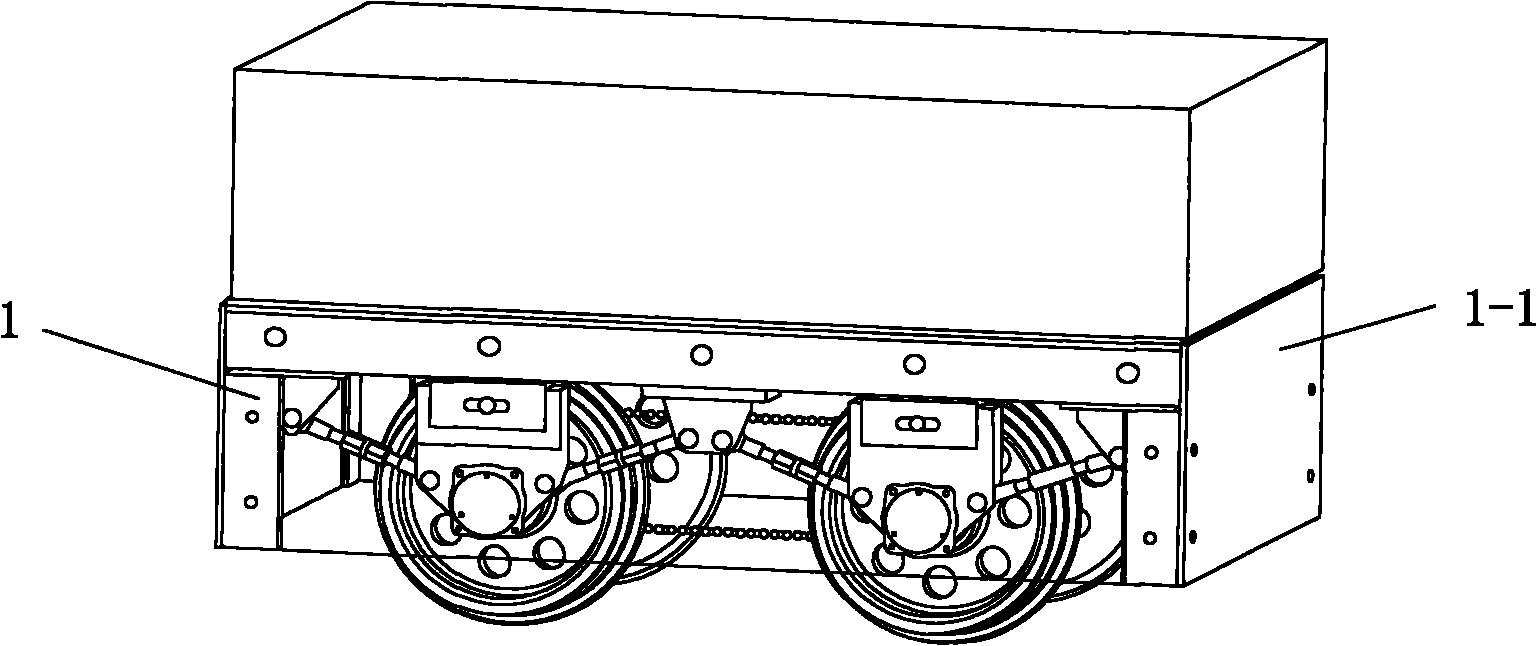

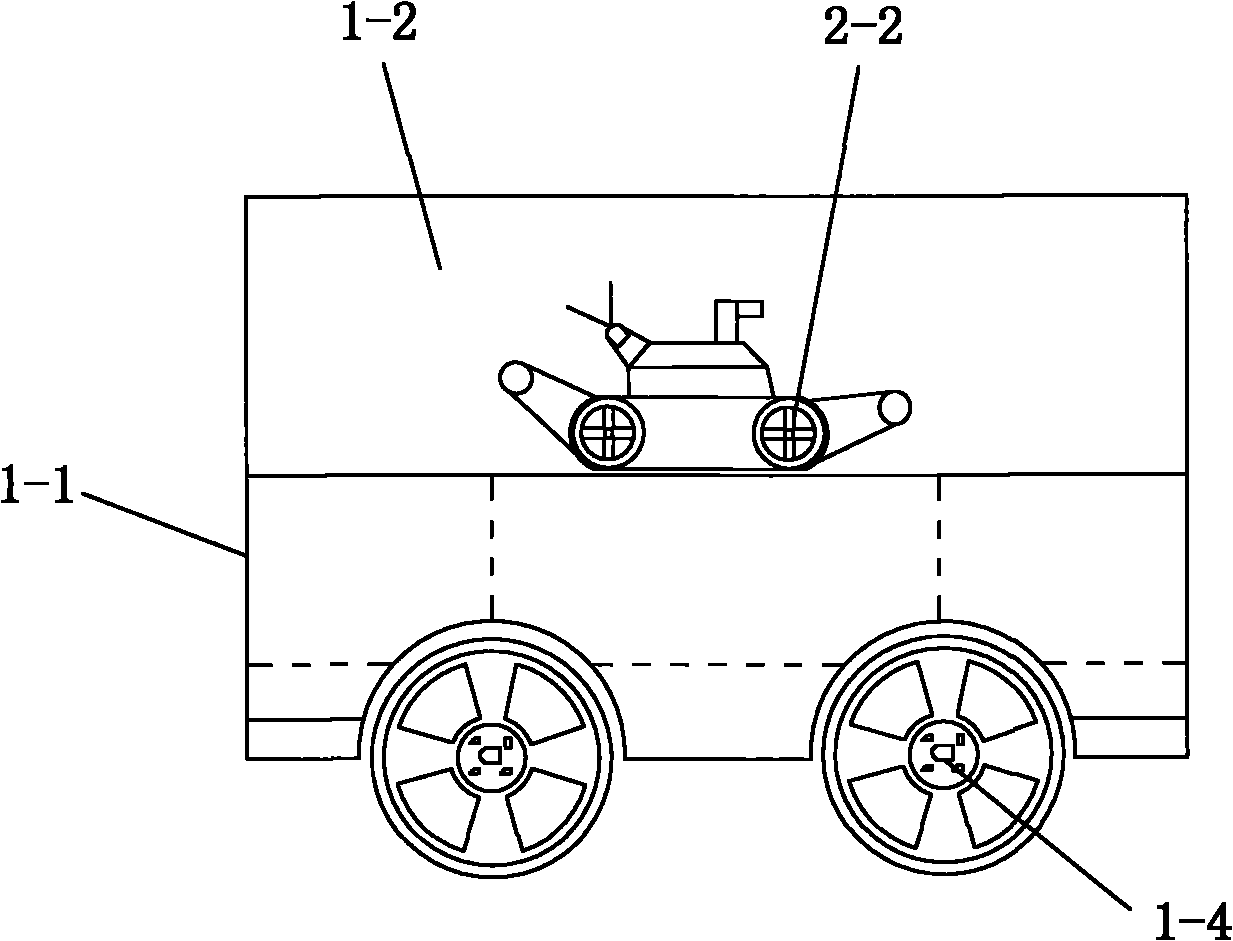

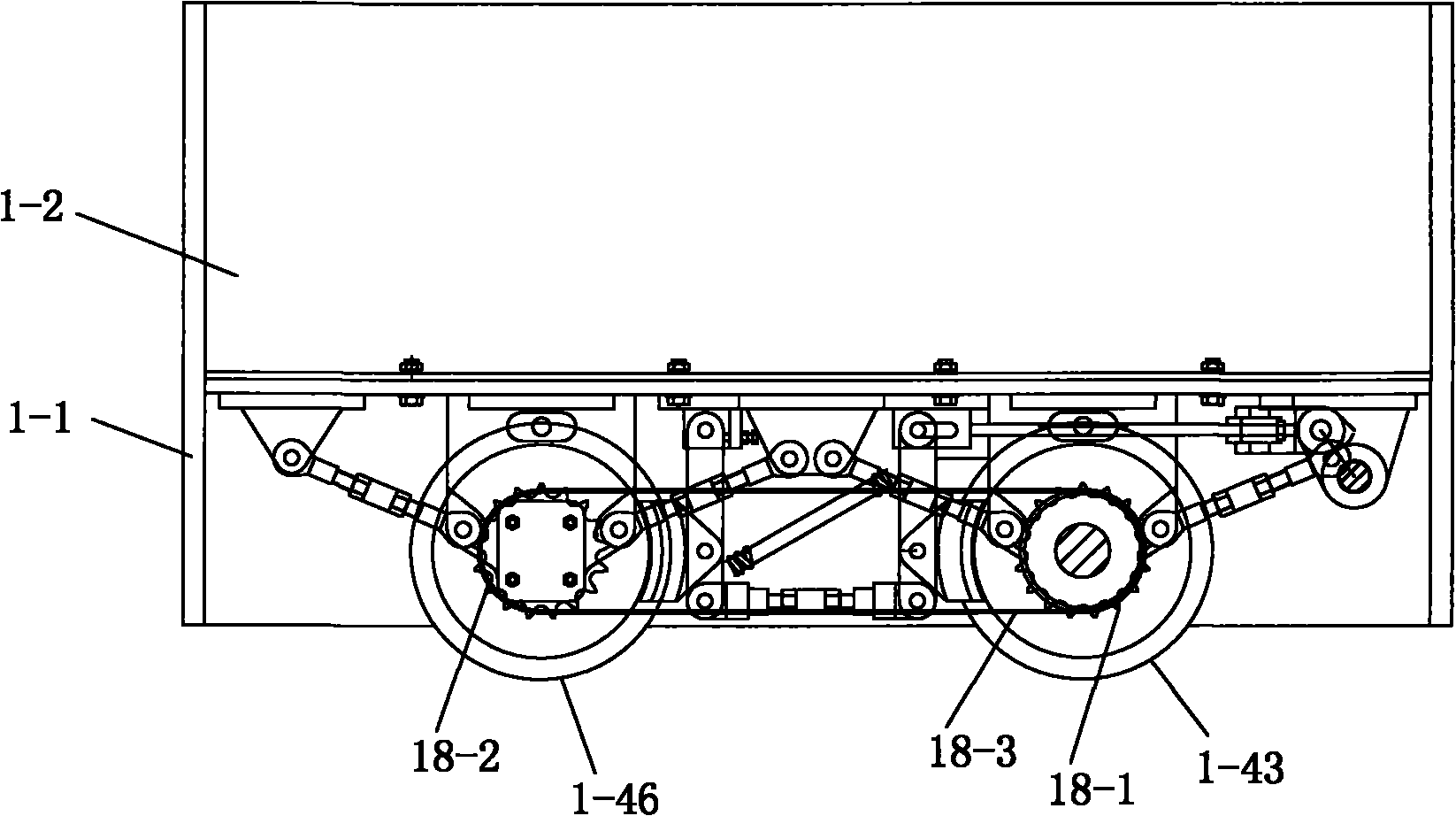

[0071] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6A coal mine rescue carrying robot shown includes a robot body 1-1, a robot storage bin 1-2 arranged in the robot body 1-1 for storing the detection robot 2, and a robot storage bin 1-2 installed in the robot storage bin 1-1. 2 on the door of the door and drive the door switch drive mechanism 1-3 of the door switch, which is installed in the robot body 1-1 and can walk along the existing transportation channel laid in the coal mine underground roadway. 1-4, the driving mechanism 1-5 that drives the traveling mechanism 1-4, the environmental information monitoring unit 1-6, the autonomous navigation unit 1-8, the ranging unit 1-10, installed on the robot body The automatic obstacle removal mechanism 1-9 on the one 1-1 and the control system one 1-7 respectively connected with the environmental information monitoring unit one 1-6, the distance measuring unit one 1-10 and the autonomous navigation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com