Chemical flooding alternate injection method

A technology of alternating injection and chemical flooding, which is used in earth-moving drilling, production of fluids, wellbore/well components, etc., can solve the problems of low production degree of low-permeability oil layers, low effective utilization rate, uneven distribution of injection volume, etc. The effect of improving the effective utilization rate, increasing the liquid absorption, and increasing the recovery factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

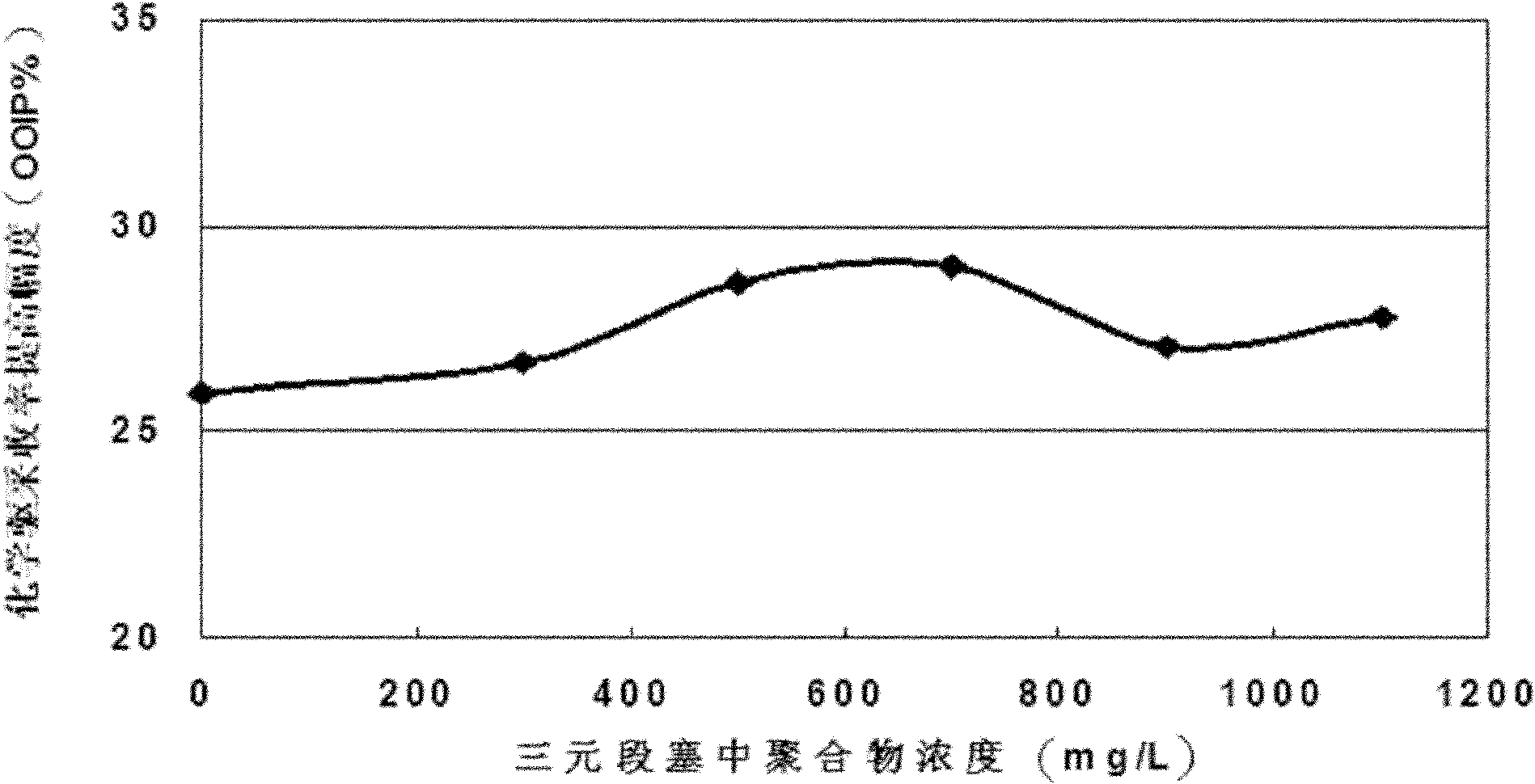

[0009] Embodiment 1: A chemical flooding alternate injection method in this embodiment is as follows: 1. Inject polymer slug A with a polymer molecular weight of 20 million to 30 million and a polymer concentration of 1600 mg / L to 2000 mg / L. 10% of the pore volume; 2. The polymer molecular weight is 10 million to 19 million, the polymer concentration is 500 mg / L to 1000 mg / L, the surfactant mass concentration is 0.2% to 0.3%, and the alkali mass concentration is 1.0% to 1.2% ternary slug, inject 10% of the pore volume; 3. Repeat step 1 and step 2 3 to 4 times; The polymer slug B of L is injected into 10%~12.5% of the pore volume, namely completes the injection of chemical flooding; the surfactant described in step 2 is alkylbenzene sulfonate, and the alkali described in step 2 is hydrogen sodium oxide.

[0010] The polymer in this embodiment is mainly used to improve the macroscopic sweep efficiency and penetrate into the high-permeability layer more, and the polymer in the...

specific Embodiment approach 2

[0011] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the molecular weight of the polymer in the polymer slug A described in step 1 is 25 million. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the polymer concentration in the polymer slug A in step 1 is 1800 mg / L. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| System viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com