Belt steel wire surface treating agent for retreading steel wire radial tire and preparation method thereof

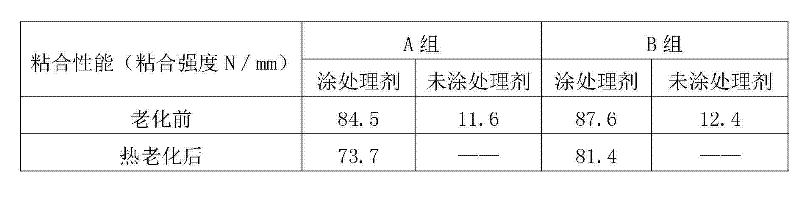

A technology of radial tire and surface treatment agent, applied in the field of metal surface treatment agent and its preparation, can solve the problems such as the inability to achieve high-strength adhesion of new tread rubber, and achieve the effects of convenient operation and prevention of re-oxidation and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with specific embodiment, further illustrate the present invention, should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various equivalent forms of the present invention All modifications fall within the scope defined by the appended claims of the present application.

[0013] A steel wire radial tire retreading belt steel wire surface treatment agent, its composition includes oxide layer remover, corrosion inhibitor, antioxidant, dispersion tackifier and water, wherein the oxide layer remover includes phosphoric acid, oxalic acid, Industrial salicylic acid and potassium ferrocyanide, the proportion of its components by mass percentage is:

[0014] Oxidation layer remover 15%~20%, corrosion inhibitor 2%~4%, antioxidant 1%~2.5%, dispersion tackifier 6%~10%, water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com