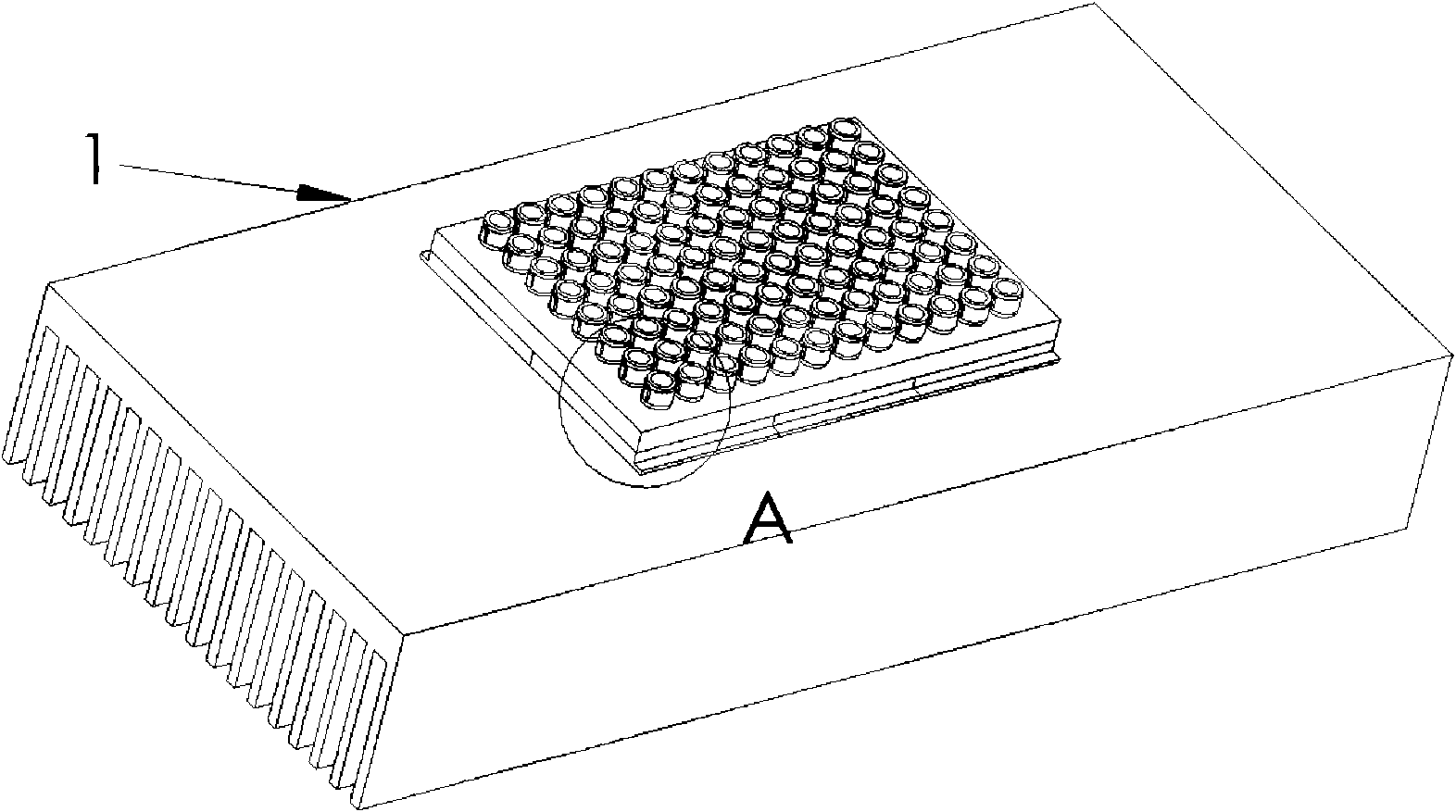

Variable-temperature metal module with precise temperature compensation and temperature compensating method

A temperature compensation, metal module technology, applied in biochemical equipment and methods, microbial determination/inspection, specific-purpose bioreactors/fermenters, etc., can solve rough temperature compensation, heat unevenness, semiconductor refrigerator power Non-uniformity and other problems, to achieve the effect of improving accuracy and repeatability, and improving temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

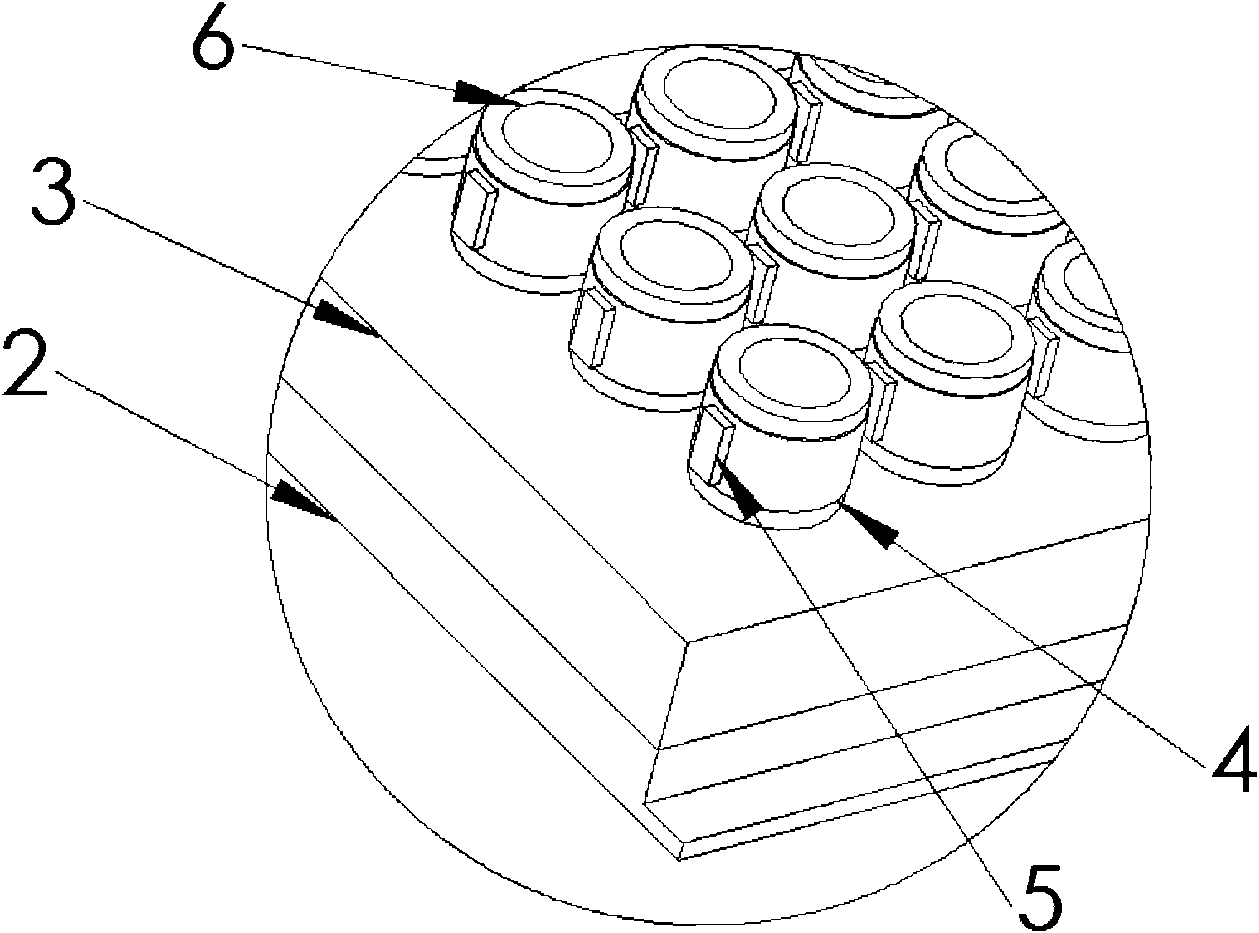

[0043] see figure 2 , image 3 , Image 6 with Figure 7 , before leaving the factory, each sample hole needs to be tested to determine which sample holes need to be individually temperature compensated, and the range of temperature compensation power, specifically: set a temperature compensation heater 5 around each sample hole, in the commonly used Within the temperature range, set the first temperature control point to 60°C, control the temperature-changing metal module to this temperature point, measure the actual temperature value of each sample hole through the temperature sensor; adjust each temperature compensation heater through the control circuit Make the actual temperature value of each sample hole as close as possible to the first temperature control point 60°C, record the actual temperature compensation power value PWM_60 of each temperature compensation heater at this time i;In the commonly used temperature range, set the second temperature control point 90°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com