Micelle oil displacement agent with oil deposit adaptability

A technology of oil displacement agent and oil displacement agent, which is applied in the field of oil field chemistry, can solve the problems of difficult to obtain oil displacement agent, complex composition of crude oil, large composition changes, etc., and achieve high interface efficiency, good reservoir adaptability, and use concentration low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

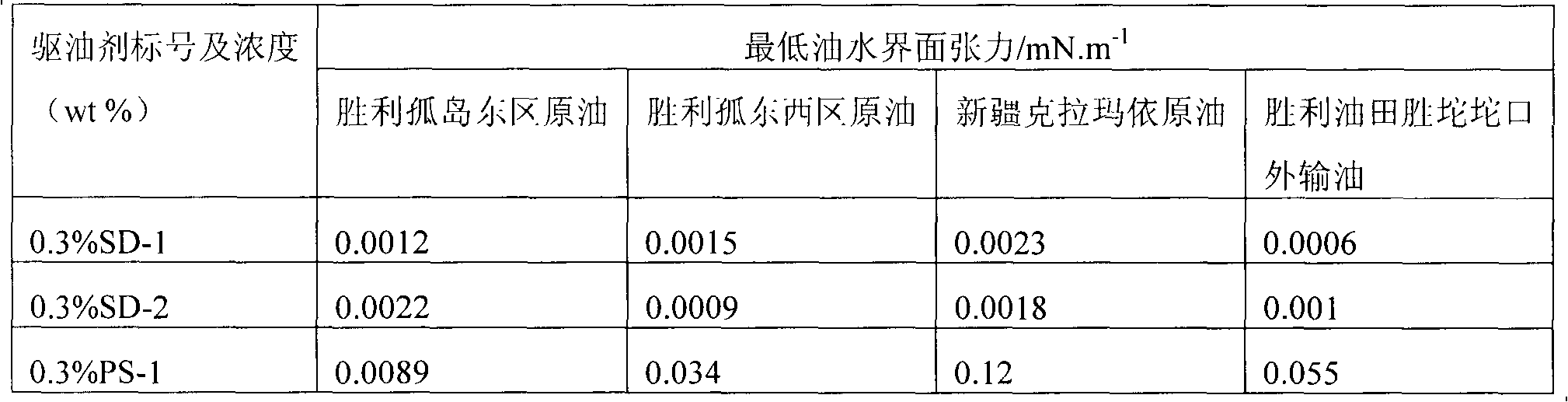

[0033] Using Gudong crude oil from Shengli Oilfield to reduce the second-line components, at a temperature of 50-55°C, SO 3 / N 2 The flow rate of the mixed gas flow is 120-160L / h, of which SO 3 The average concentration is 3.0-5.0g / L, after a reaction time of 3-6 hours; add sodium hydroxide for neutralization to obtain petroleum sulfonate. Mix 90 parts of petroleum sulfonate with 30 parts of cetyl polyoxyethylene ether (produced by Shandong Binzhou Chemical Factory), stir and mix evenly, then slowly add 15 parts of octylamine dropwise while stirring, the solution is clear and transparent, then stir While slowly adding 315 parts of water, that is. Designated as SD-1.

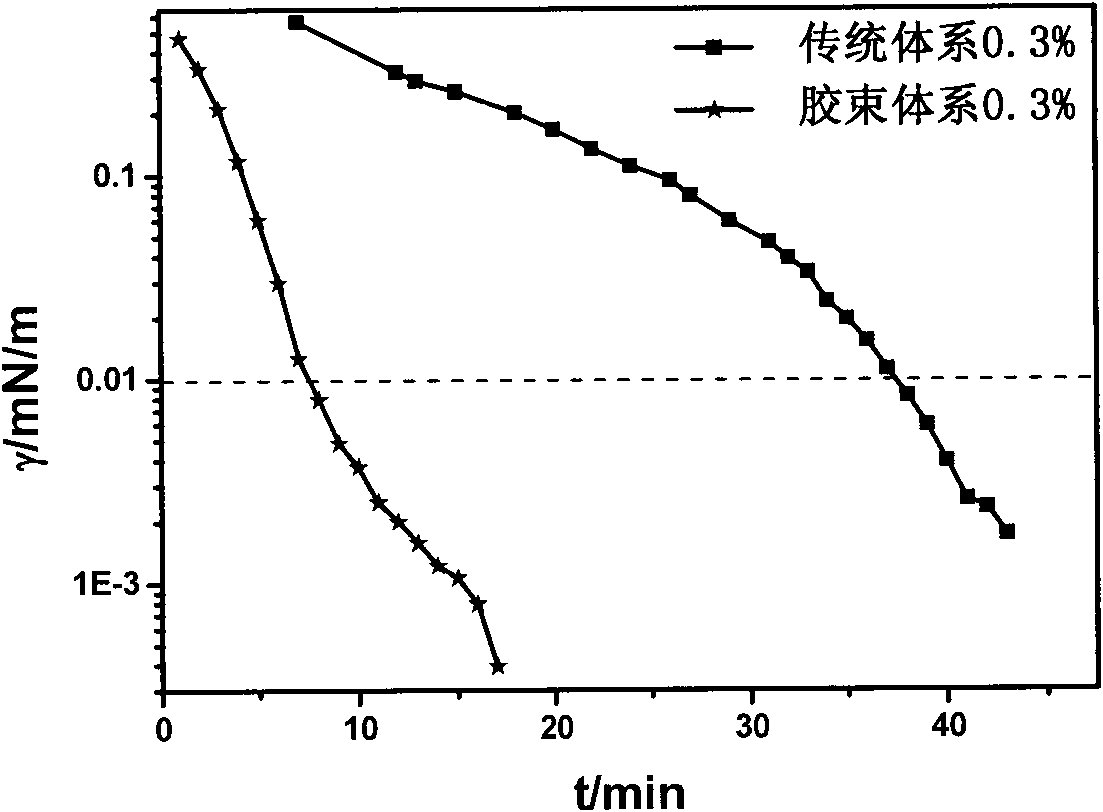

[0034] Take 1 part of SD-1, mix it with 100 parts of Gudong Formation Water of Shengli Oilfield, and stir well. Adjust the TEXAS-500 spinning drop interfacial tensiometer to 40°C, put the sample tube filled with the above solution, and after stabilizing for half an hour, add about 1 microliter of Shengli Guda...

Embodiment 2

[0038] Mix 72 parts of sodium dodecylbenzene sulfonate (produced by Zibo Luqian Chemical Factory) with 18 parts of alkanolamides (produced by Sichuan Huayu Co., Ltd.), stir continuously at 40°C, mix well, and then In some cases, add 10 parts of octanol dropwise. After the solution is clear and transparent, add 400 parts of water while stirring to obtain the product. Designated as SD-2.

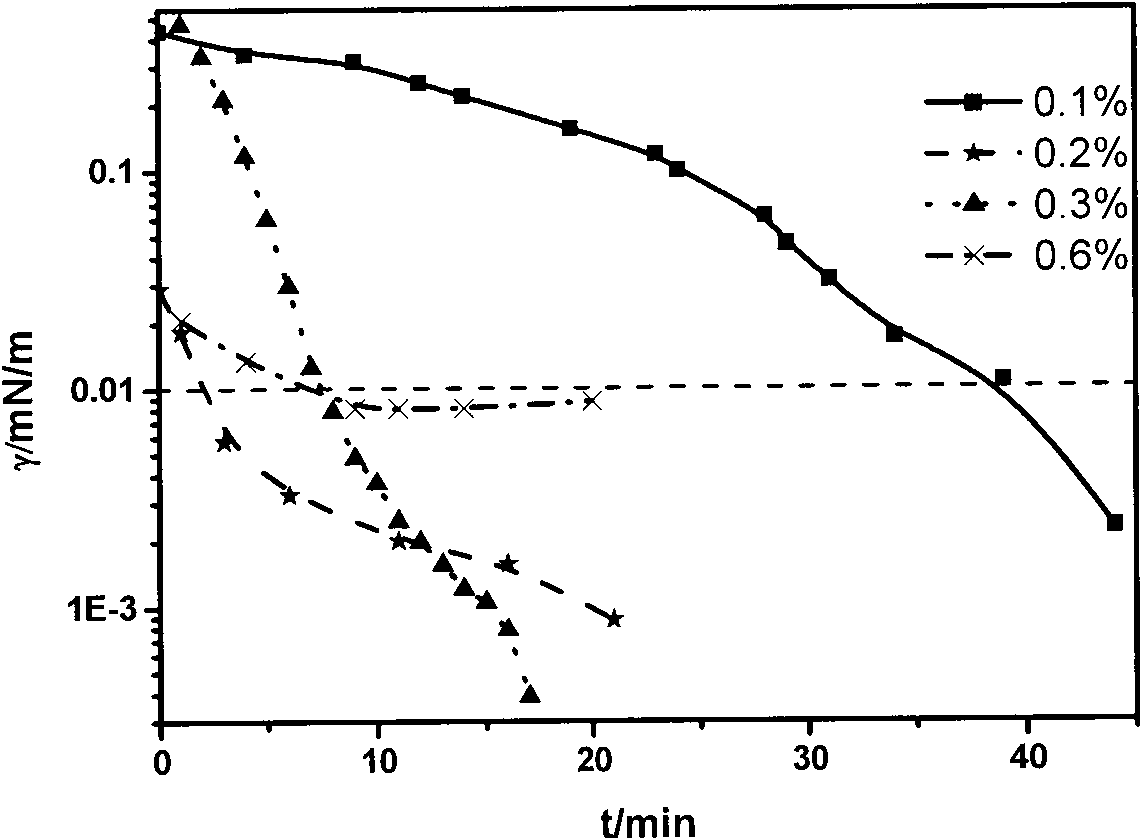

[0039]Take 1 part of SD-2, and slowly add 199 parts, 99 parts, 66 parts and 32 parts of Gudong formation water of Shengli Oilfield at 25°C while stirring, so that the total concentrations of A, B, and C in the solution are respectively 0.1, 0.2, 0.3, 0.6 wt%. According to the same steps as Example 1, according to the national standard SY / T5370-1999 method, measure the dynamic interfacial tension curve between the system and the crude oil in the east area of Shengli Gudao, the results are shown in figure 2 . As can be seen from the figure, the micellar oil displacement agent can quickly r...

Embodiment 3

[0041] Mix 65 parts of petroleum sulfonate (produced by Shengli Oilfield Zhongsheng International Petrochemical Group Co., Ltd.) with 35 parts of nonylphenol polyvinyl ether (produced by Zhejiang Zanyu Technology Co., Ltd.), stir and mix evenly, and then Slowly add 25 parts of butanol dropwise. After the solution is clear and transparent, slowly add 375 parts of water while stirring to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com