Novel lithium ion polymer battery thickness control device

A technology of thickness control and lithium ion, which is applied in the field of new lithium ion polymer battery thickness control device, can solve the problems of negative impact on battery capacity and cycle performance, breakage of battery tabs, and increased difficulty of battery production workers, etc., to achieve guaranteed Quality qualification rate and overall performance, significant production practice significance, and the effect of improving market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

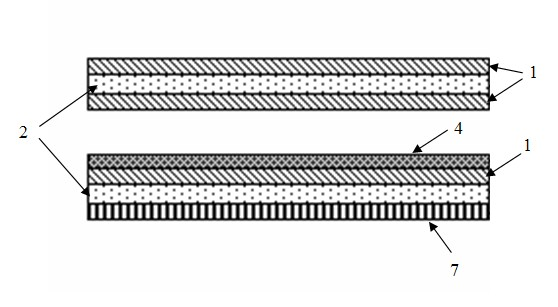

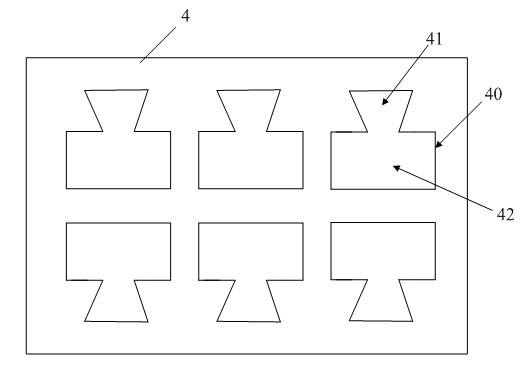

[0024] figure 1 It is a schematic structural diagram of a cold-pressed template in a novel lithium-ion polymer battery thickness control device provided by the present invention.

[0025] see figure 1 , the present invention provides a novel lithium-ion polymer battery thickness control device, which can be used to control the thickness of the battery during the battery formation process and follow-up process, including a cold press and a cold press template 4, the cold press There are six hollowed out grooves 40 on the template 4, and the battery that needs to be cold-pressed and shaped to control the thickness is placed in the groove 40, and the battery is cold-pressed and shaped by the cold press;

[0026] see figure 1 , in the present...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com