EHT (Extra High Tension) self-cleaning energy-saving environment-friendly device and manufacture method thereof

An energy-saving and environmental-friendly manufacturing method technology, applied in the direction of cleaning heat transfer devices, cleaning methods and utensils, cleaning hollow objects, etc., can solve problems such as difficult to achieve enhanced heat transfer and anti-scaling and descaling effects, and achieve enhanced and enhanced heat transfer And the effect of anti-scaling and descaling, improving work efficiency and enhancing the effect of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

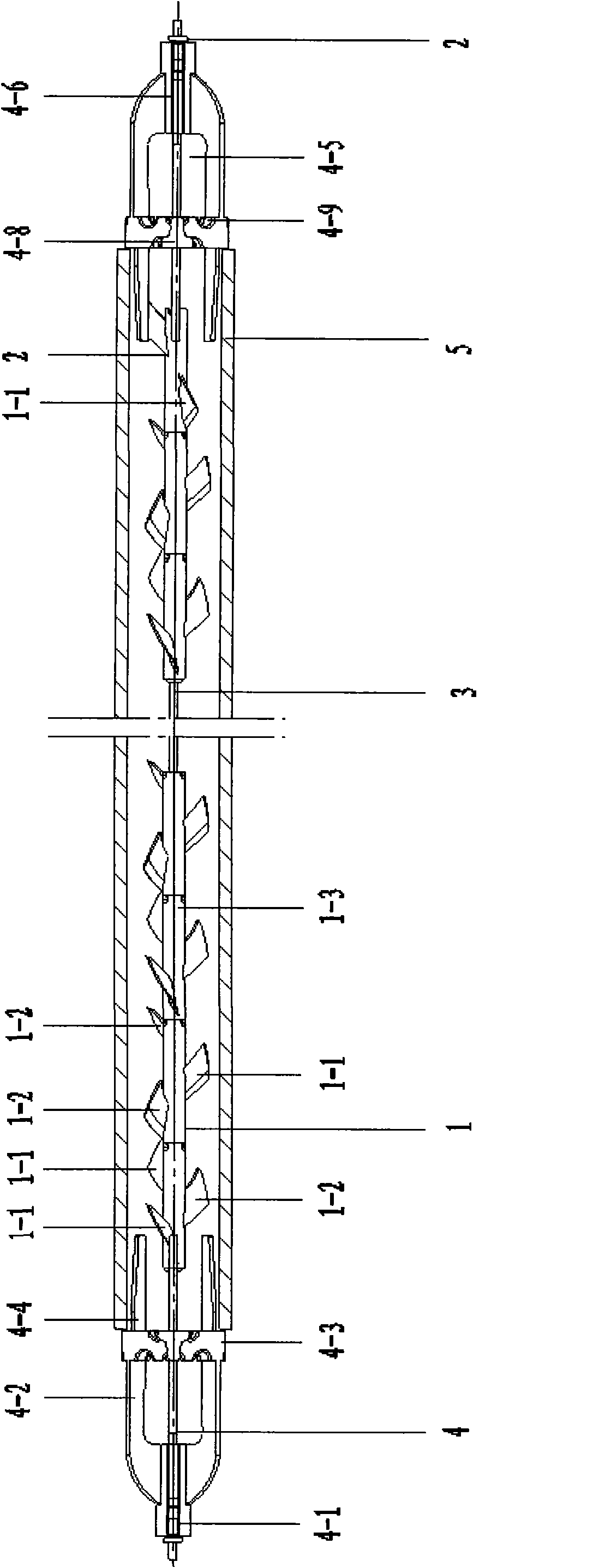

[0024] like figure 1 As shown, the EHT self-cleaning energy-saving and environmental protection device includes a rotor 1, a rotating shaft 3, a limiting member 2 and a pendant 4. 4 fixed, the pendant 4 is fixed at both ends of the heat exchange tube 5 .

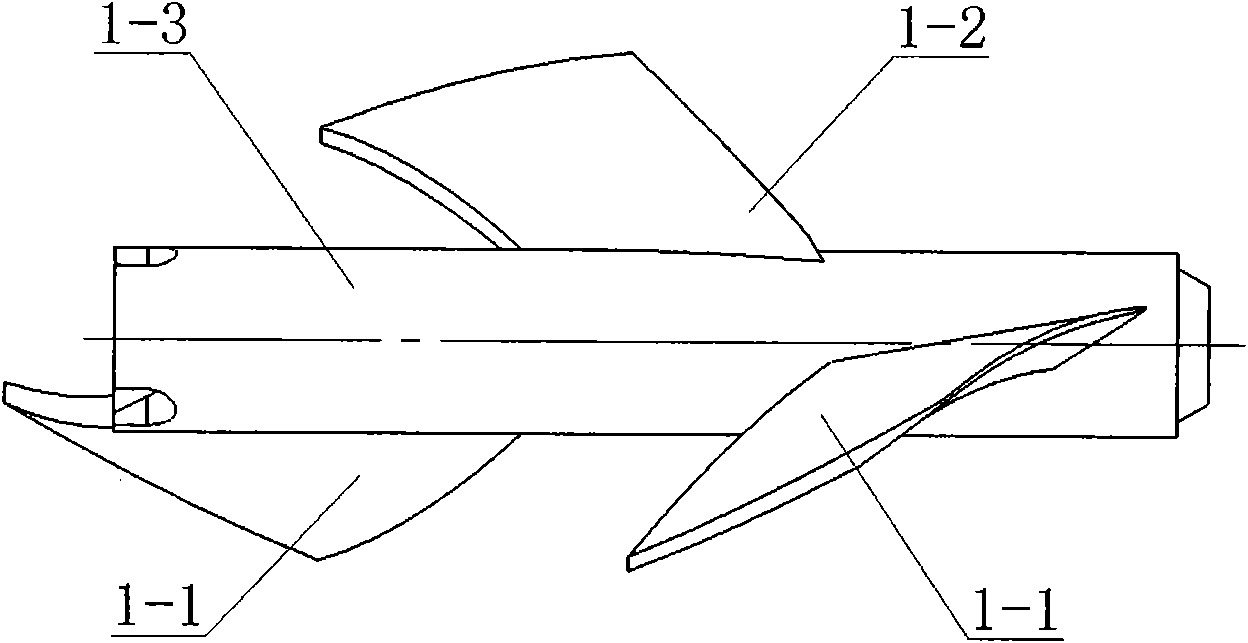

[0025] exist Figure 1 to Figure 8 middle, figure 1 Shown is a schematic diagram of the structure of the EHT self-cleaning energy-saving and environmental protection device. figure 2 is the front view of the left-hand rotor, the left-hand rotor has two left-handed blades 1-1 and one right-handed blade 1-2, image 3 Yes figure 2 left view of Figure 4 is the front view of the right rotor, the right rotor has two right rotor blades 1-2 and one left rotor blade 1-1, Figure 5 Yes Figure 4 left view of Image 6 It is a three-dimensional structural schematic diagram of a two-leaf left-handed rotor, including two left-handed blades 1-1, which serve as the stopper 2 at the end of the rotor 1 in the embodiment, Figure 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com