Pitch-varying helical metal rubber composite spring

A metal-rubber and composite spring technology, applied in the field of helical compression metal springs and variable-pitch helical metal-rubber composite springs, can solve the problems of poor application effect, short service life, and high maintenance frequency, and achieve low noise, long service life and load bearing capacity. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

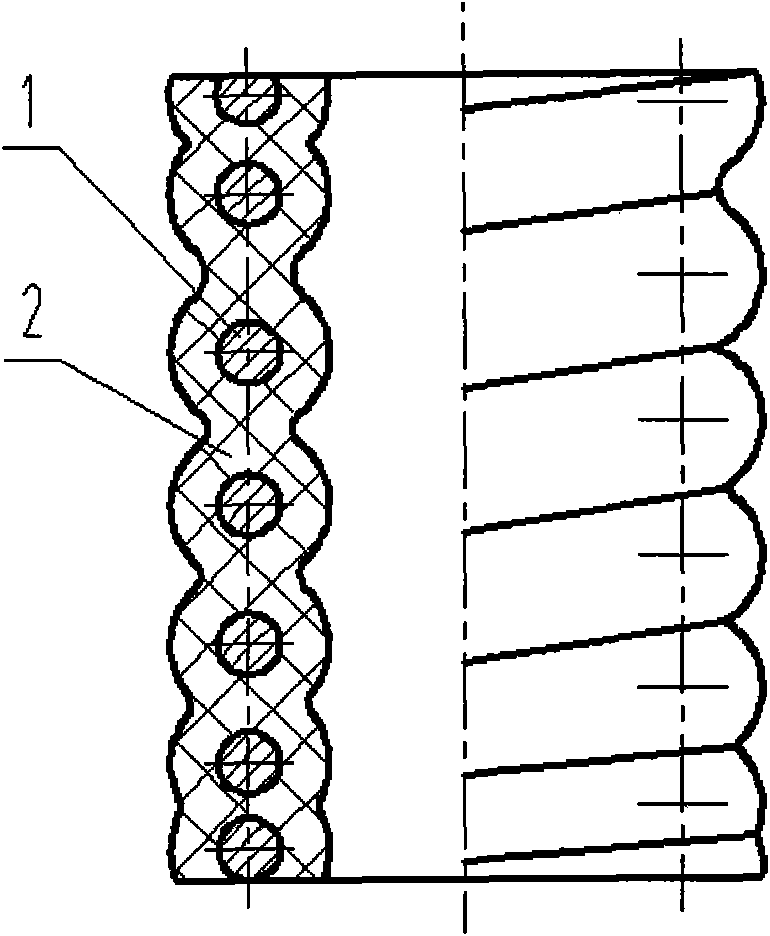

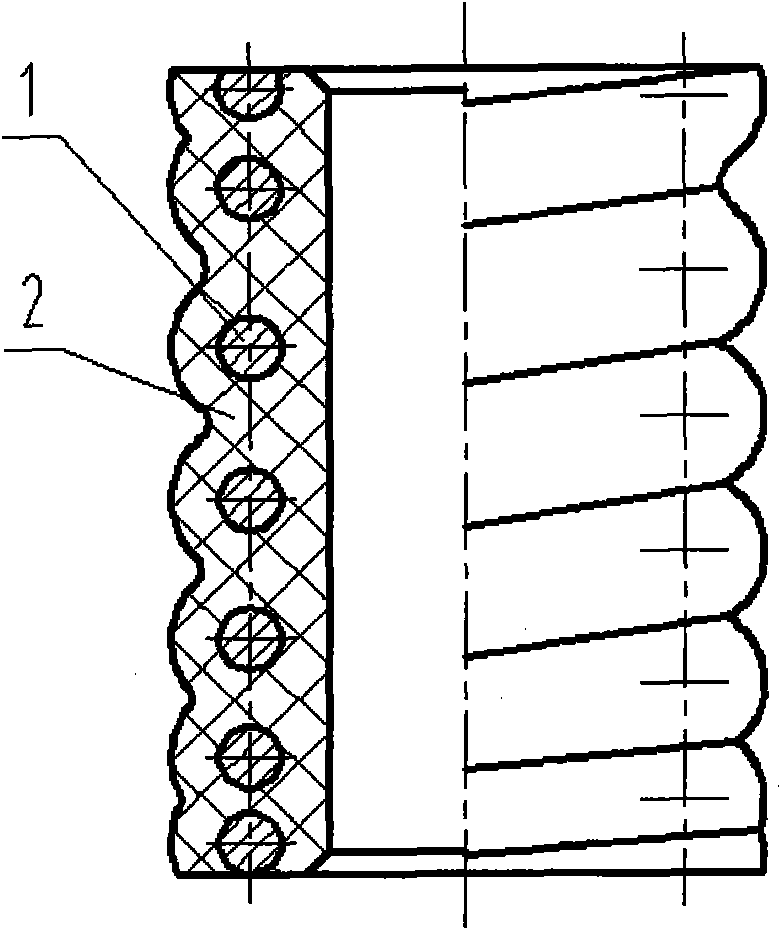

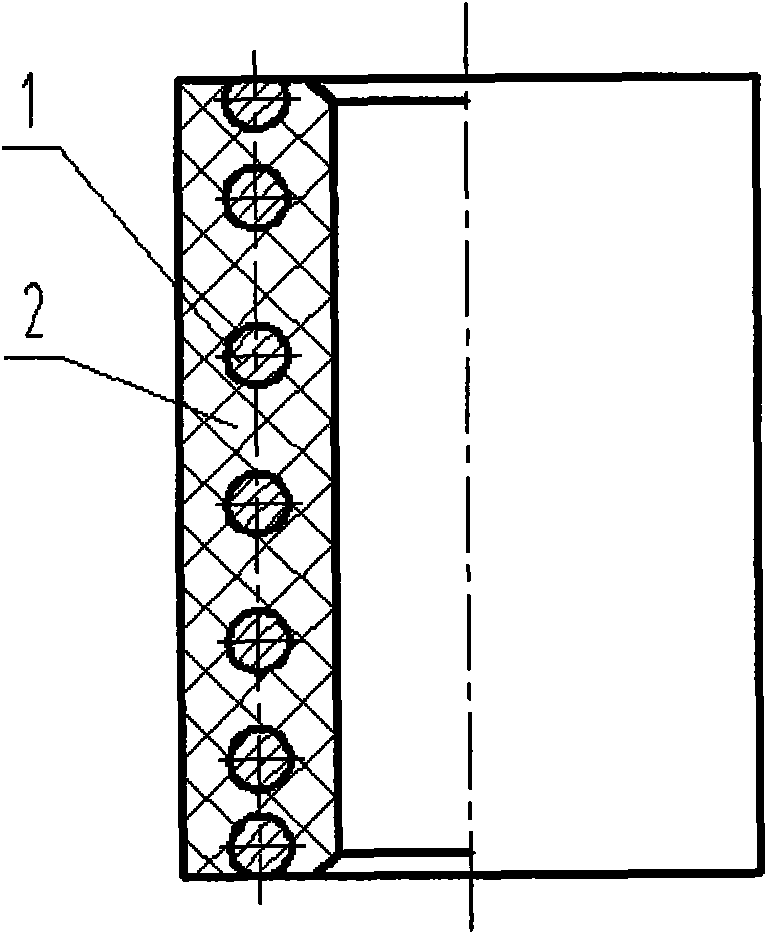

[0024] Figure 1-4 They are various types of structures of the present invention, which are respectively composed of a metal coil spring 1 and a rubber coating layer 2 . The metal coil spring 1 plays the role of supporting the skeleton, and the rubber coating layer 2 will increase the nonlinear characteristics and damping properties of the spring, and play the role of improving the bearing capacity, increasing or decreasing the system stiffness and reducing noise and vibration during operation.

[0025] Figure 5-8 They are various structures of the present invention, except that the upper and lower ends or one end are vulcanized with metal parts 3, the other structures are the same; their bearing uniformity is better, so they are more suitable for heavy loads and variable loads.

[0026] The variable-pitch helical metal-rubber composite spring is composed of two parts: a variable-pitch helical metal spring 1 and a rubber coating layer 2 . The variable-pitch helical metal sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com