Hydraulic synchronous jacking device of die carrier system

A hydraulic synchronous jacking and system technology, which is applied to formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problem of large construction space, high initial installation position, and horizontal structure lag shear wall. There are many problems such as the number of layers, to achieve the effect of good turnover, liberation of labor, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment one sees figure 1 As shown, the low-level jacking steel platform formwork system includes a formwork system hydraulic synchronous jacking device supported on the core tube shear wall 8, which is connected to the formwork system hydraulically synchronously through the support column 3 of the standardized low-position jacking formwork system. The steel platform 1 above the jacking device, and the hanger 2 and the template 7 suspended on the steel platform 1. The steel platform can be an ordinary steel frame platform or an assembled variable steel truss platform, and the hanger can be an ordinary hanger or an adjustable hanger. The entire formwork system of the low-level jacking steel platform often requires three or four sets of hydraulic synchronous jacking devices for the formwork system.

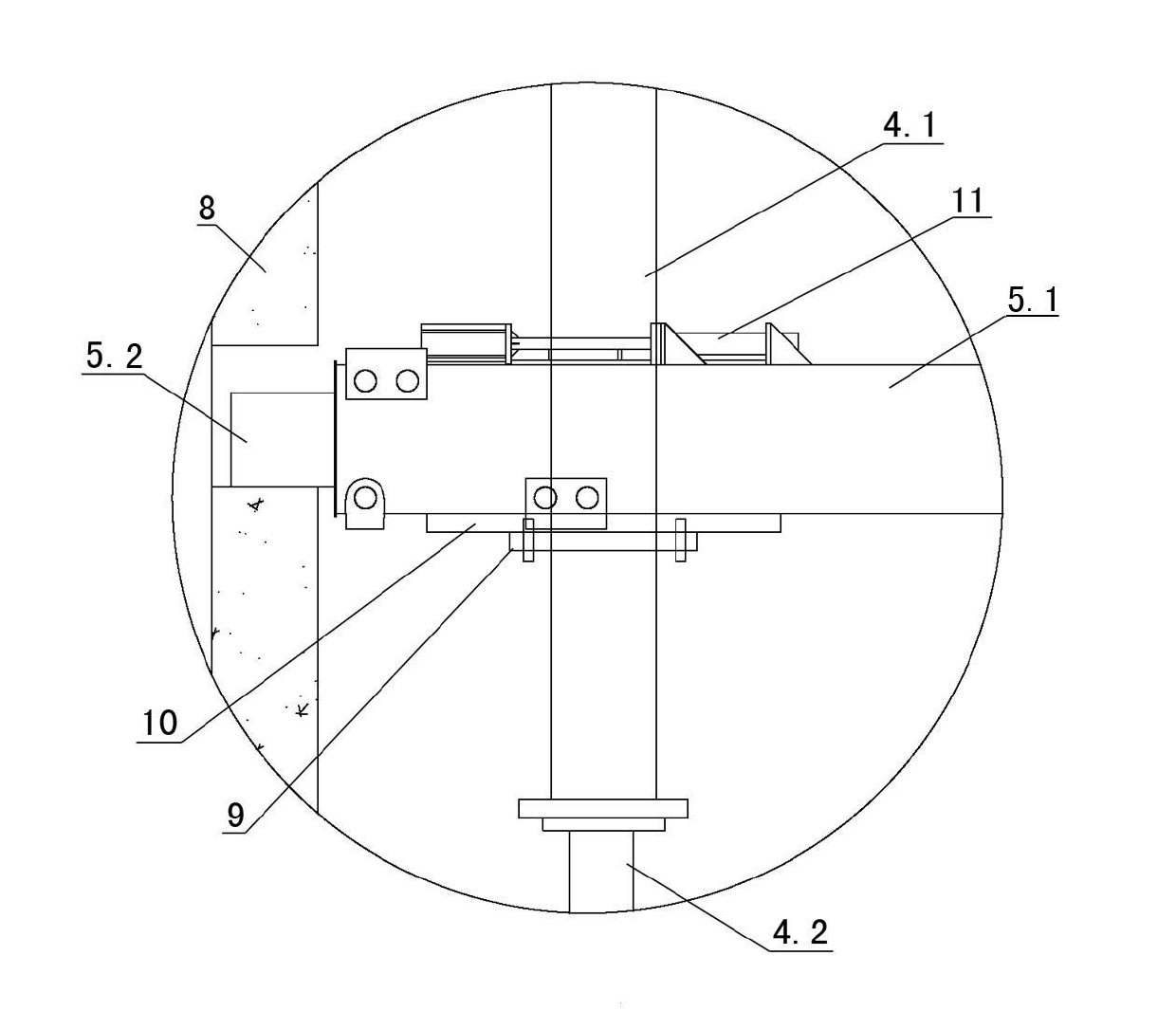

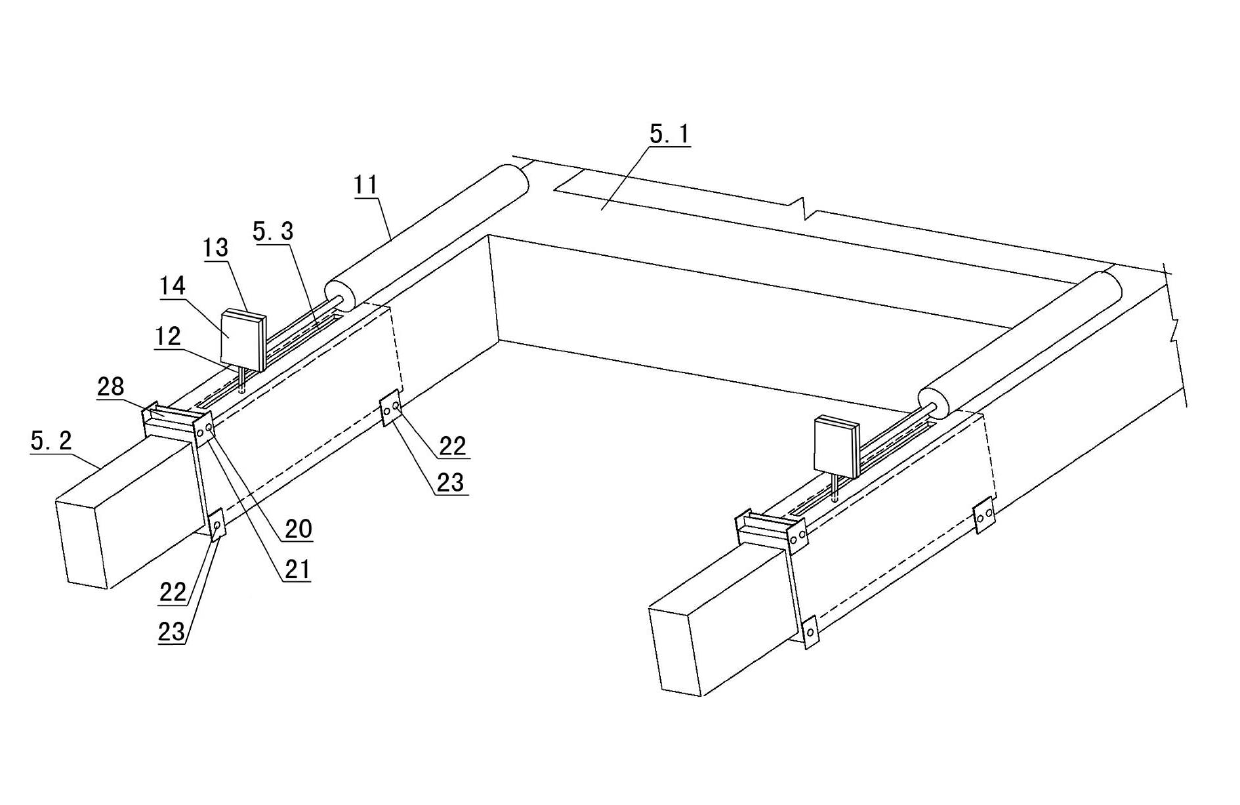

[0029] see figure 1 , Figure 4 , Figure 5The hydraulic synchronous jacking device of the formwork system includes an upper support beam 5, a lower support beam 6 and...

Embodiment 2

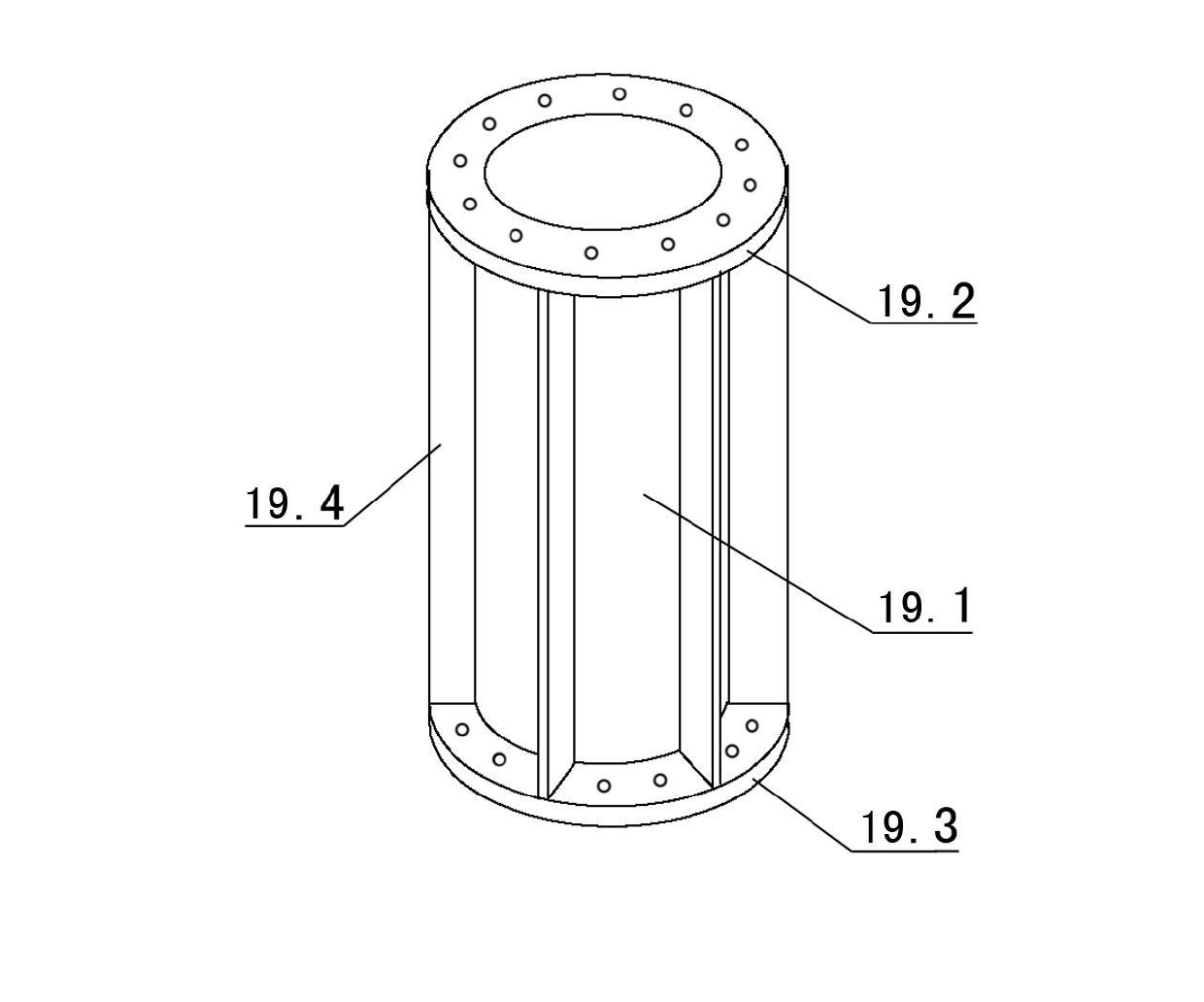

[0035] Embodiment two see figure 2 , there is an increasing section 19 connected between the lower end of the piston rod 4.2 of the jacking cylinder 4 and the lower support beam main body 6.1, see image 3 , the added section 19 includes a round steel pipe 19.1, the upper end of the round steel pipe 19.1 is connected with an upper flange 19.2, the lower end of the round steel pipe 19.1 is connected with a lower flange 19.3, an upper flange 19.2, and a lower flange 19.3 Also be connected with back corrugated 19.4 between the sidewall of round steel pipe 19.1. The added section is connected to the piston rod through the upper flange and bolts, and the added section is connected to the main body of the lower support beam through the lower flange and bolts. The distance between the upper and lower support beams can be adjusted by adding or canceling the added section.

[0036] see Figure 7 , the present invention also has a pumping station 34, a touch-type operating table 35,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com