Technology for leading gaseous fluorine and solid iodine to carry out reaction for preparing iodine pentafluoride under room temperature

A technology of iodine pentafluoride and solid iodine, which is applied in the direction of interhalogen compounds, can solve environmental pollution and other problems, and achieve the effect of solving environmental pollution problems, simple preparation and reasonable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

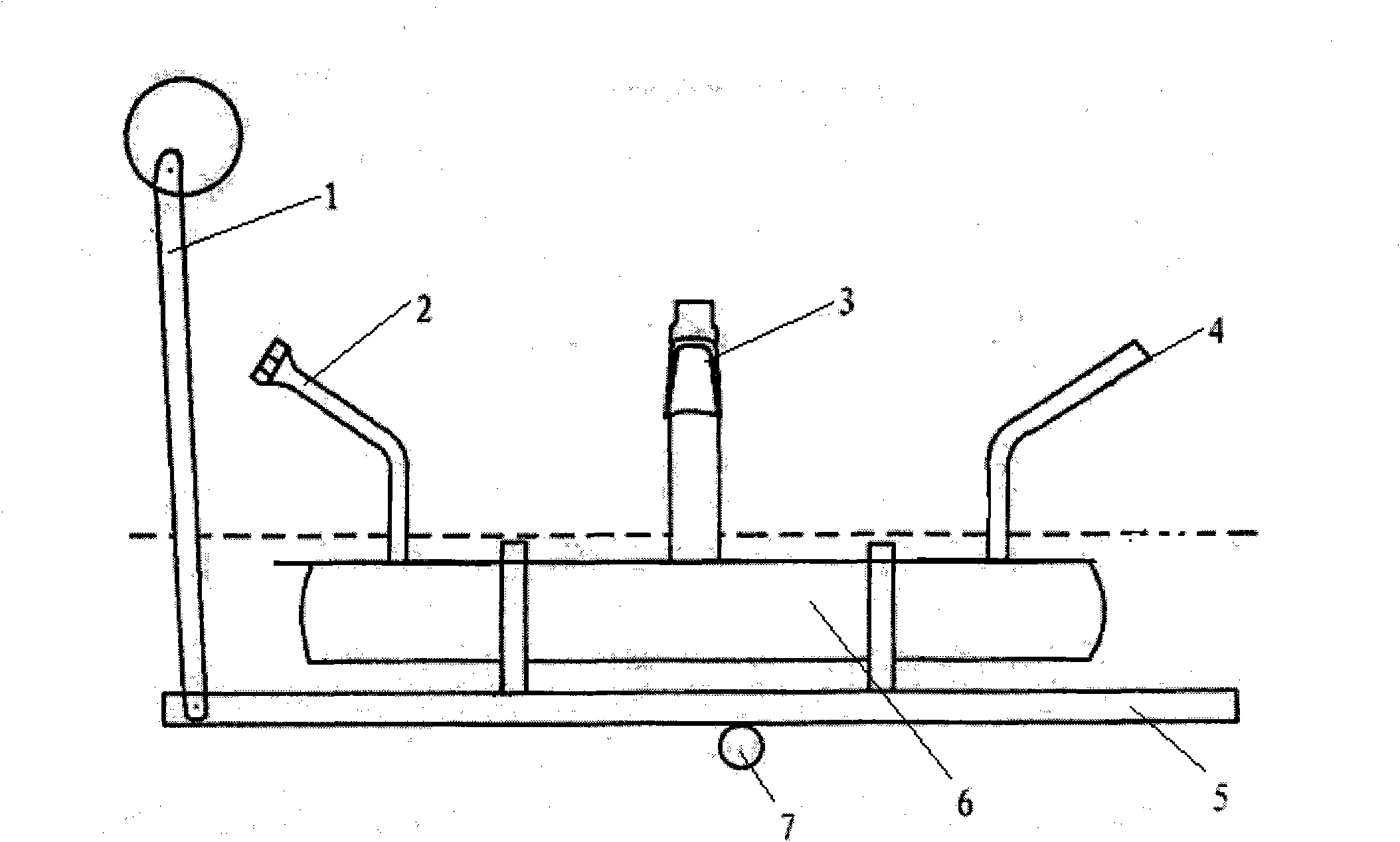

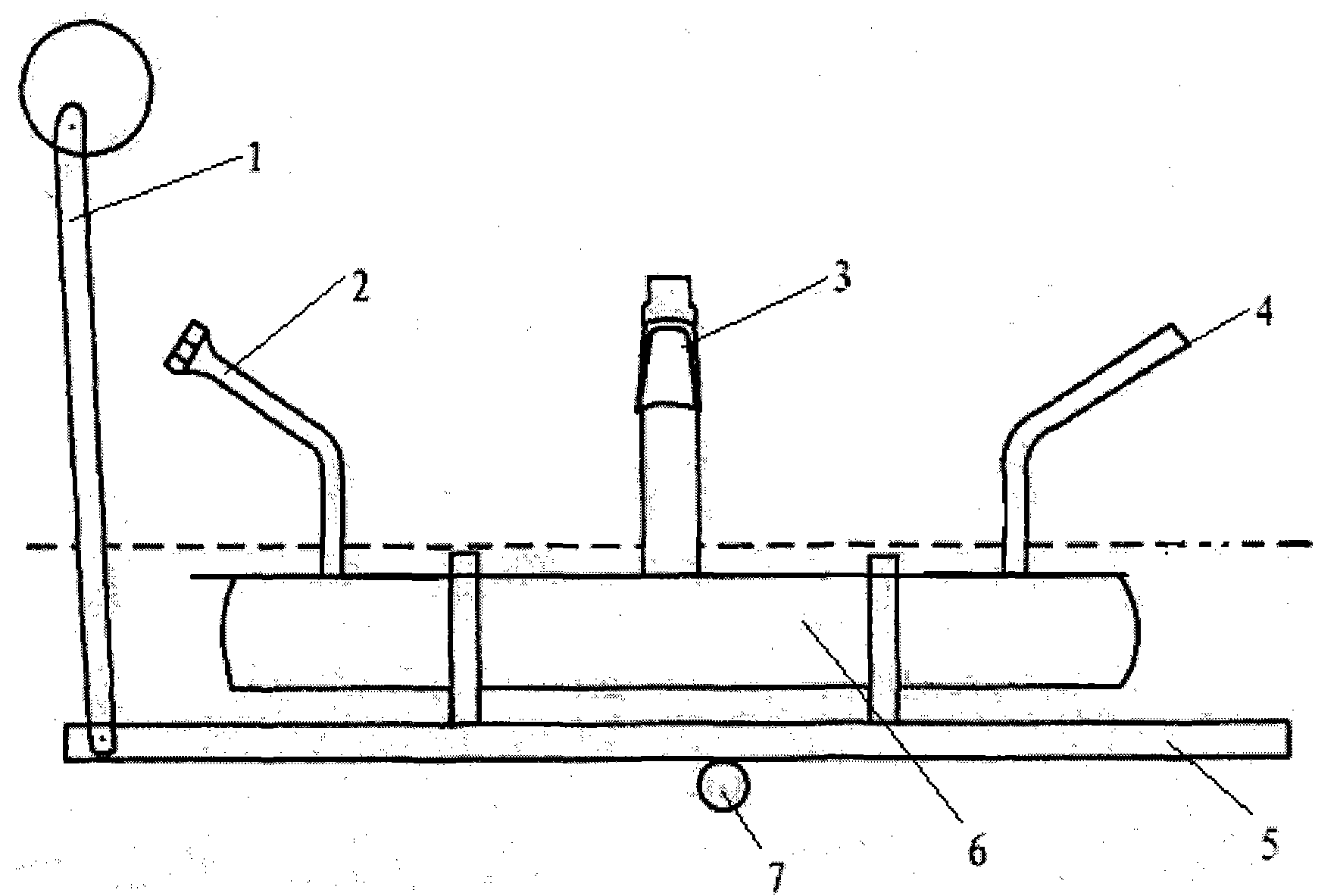

[0010] refer to figure 1 , make an integrated reactor 6, connect and install fluorine gas inlet pipe 2, iodine powder adding pipe 3 and tail gas test pipe 4 on it, its assembly is installed on the platform 5 that is connected with fulcrum 7 under it, eccentric wheel 1 It is installed on the side of platform 5 and assembled into one body.

[0011] Reactor 6 is a nickel or stainless steel pipe, and pipe 3 is filled into iodine powder from iodine powder. The cover that iodine powder adds on the pipe 3 is lubricated with polychlorine or fluorine-chlorine lubricant. When the installed platform 5 oscillates on the fulcrum 7 by means of the eccentric wheel 1 , water flows continuously through the outside of the reactor 6 . The fluorine gas enters the reactor 6 through the fluorine gas inlet pipe 2 to react with the iodine powder, and the oscillation is to prevent the iodine pentafluoride covering layer from being continuously generated on the iodine surface. When the reaction was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com