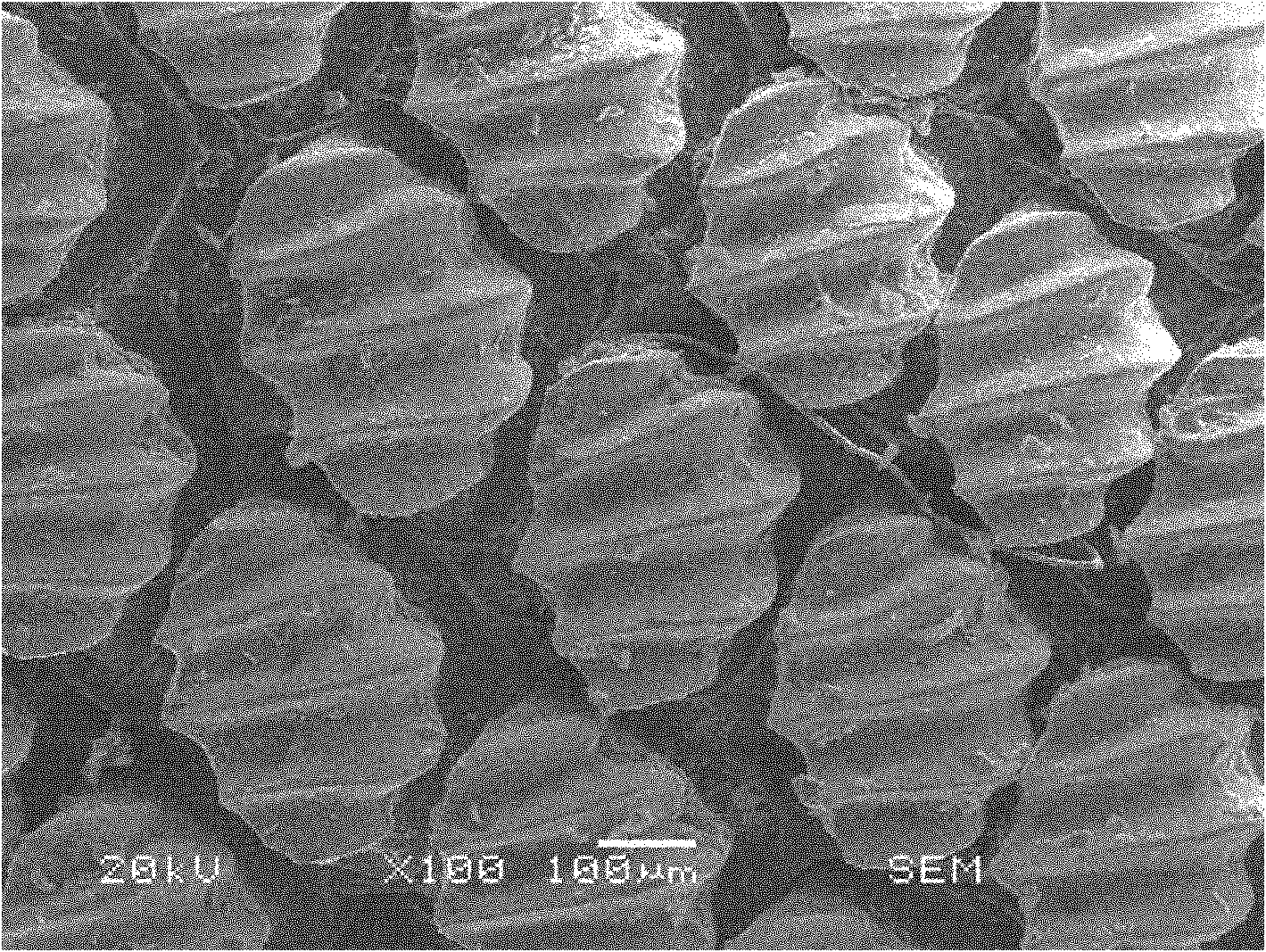

Method for copying sharkskin surface micro groove structure

A replication method and shark skin technology, applied in the field of biological restraint molding, can solve the problems of difficulty in demoulding, low replication accuracy of shield scales, etc., achieve the best drag reduction effect, and solve the effect of low replication accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

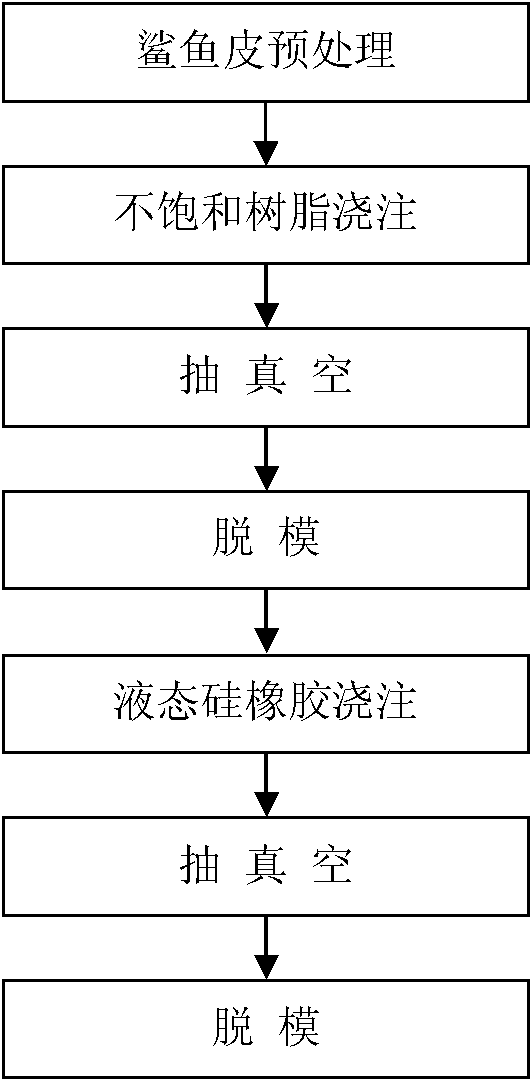

[0021] Step 1 Shark Skin Pretreatment

[0022] Remove the muscles, tendons and other subcutaneous tissues on the back of the fish skin; use ethanol gradient solution to dehydrate twice, each time for 20 to 30 minutes; clamp the fish skin with two glass plates and put it in a drying box, at 45 °C Dry under the same conditions for 30 to 40 minutes to obtain a shark skin copy sample;

[0023] Step 2 Unsaturated resin pouring

[0024] Fix the shark skin sample on the bottom of the container, spray an appropriate amount of dry release agent on the surface of the sample; mix the unsaturated resin 191, accelerator, and curing agent uniformly in a mass ratio of 100:2.3:2.3, and then pour it into the container;

[0025] Step 3 Vacuum

[0026] Put the container in a vacuum desiccator to evacuate, stop vacuuming when the pressure reaches 10-20Pa, and keep the pressure for 10-20 minutes;

[0027] Step 4 unsaturated resin demoulding

[0028] The unsaturated resin and the fish skin samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com