Polydopamine microcapsules and preparation method thereof

A polydopamine microcapsule and dopamine technology, which is applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of poor process controllability, adhesion of microcapsules, poor controllability, etc., and achieves simple operation, good stability, and particle size. controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Dissolve 30 mg of sodium polystyrene sulfonate (PSS) in 15 mL of filtered calcium chloride solution (with a concentration of 0.2M), and add 15 mL of filtered 0.2M sodium carbonate solution to the solution at a rotation speed of 1000 rpm React in the electromagnetic stirrer for 15 seconds, turn off the electromagnetic stirring and let it stand for 15 minutes, then turn on the electromagnetic stirring, stir the reaction solution evenly, and add 5 mL to the centrifuge tube. Take a total of 4 tubes. Centrifuge the 4 tubes of suspension in a centrifuge with a rotating speed of 3000 rpm for 3 minutes and then wash with deionized water, and repeat the centrifugation-washing operation twice.

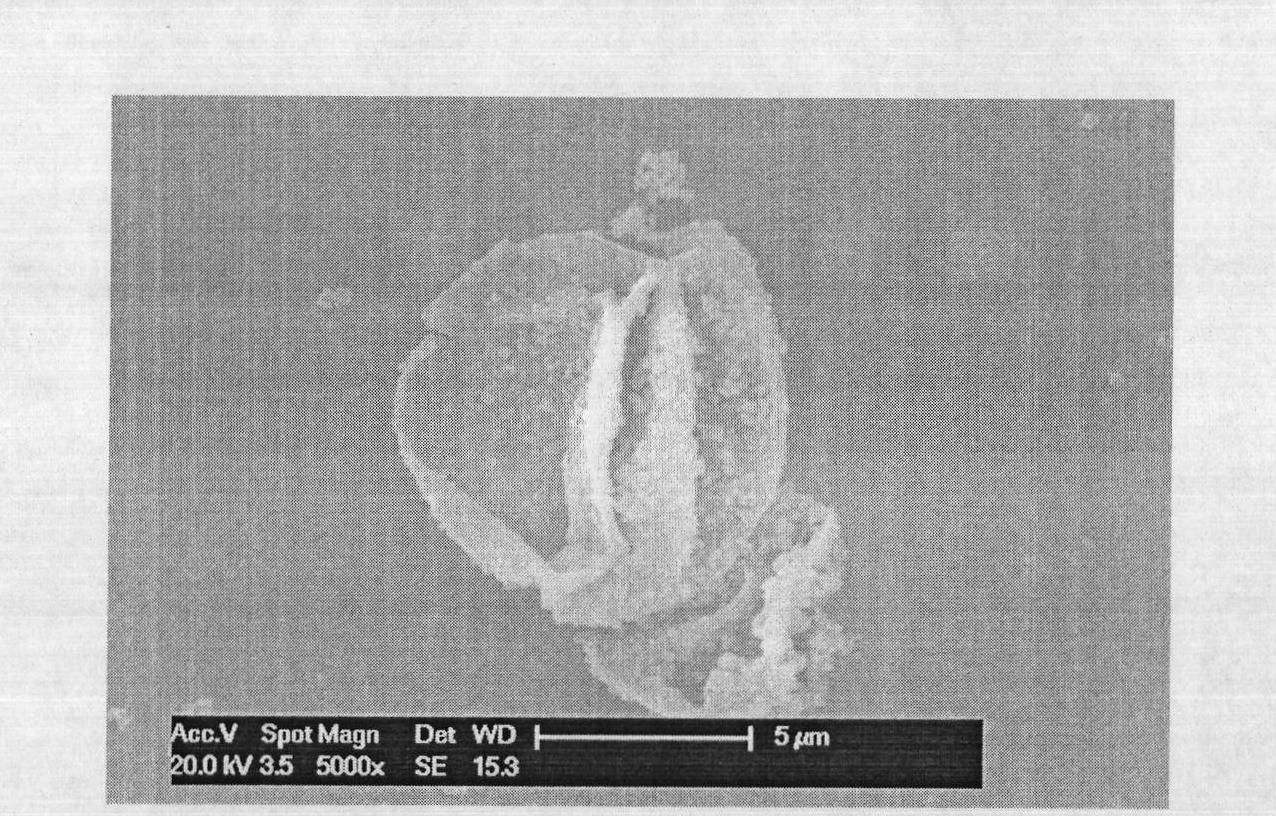

[0024] Prepare 0.01M Tris-HCl buffer solution, adjust its PH to 6.5, and prepare 2mg / mL dopamine solution. After adding the dopamine solution to the washed calcium carbonate and stirring for 48 hours, the solid particles were collected by centrifugation at 3000 rpm for 3 minutes, and 5 mL of...

Embodiment 2

[0026] Dissolve 45 mg of sodium polystyrene sulfonate (PSS) in 15 mL of filtered calcium chloride solution (concentration of 0.3M), and add 15 mL of filtered 0.3M sodium carbonate solution to the solution at a rotation speed of 1000 rpm React in an electromagnetic stirrer for 20 seconds, let it stand for 20 minutes and then turn on electromagnetic stirring to mix the reaction solution evenly, add 5 mL to the centrifuge tube, and take 4 tubes in total. Centrifuge the 4 tubes of suspension in a centrifuge with a rotating speed of 3000 rpm for 3 minutes and wash with deionized water, and repeat the centrifugation-water washing operation twice.

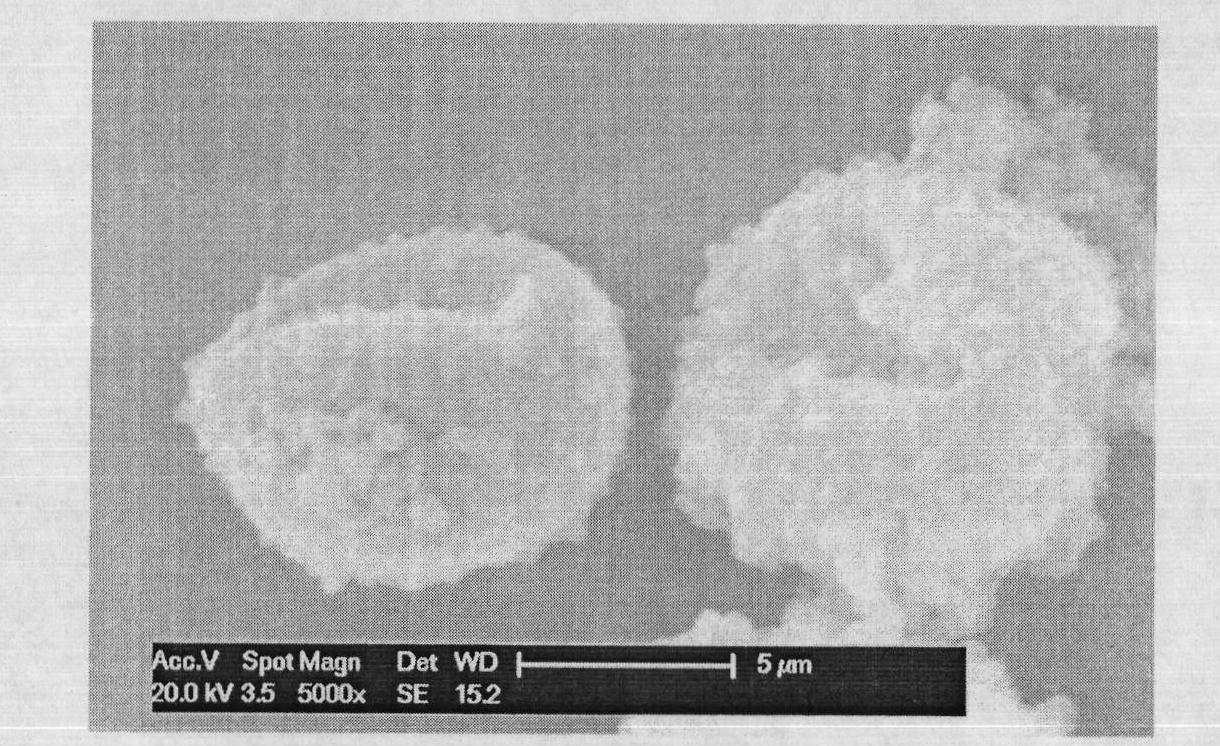

[0027] Prepare 0.02M Tris-HCl buffer solution, adjust its pH to 7.5, prepare 5mg / mL dopamine solution. After adding the dopamine solution to the washed calcium carbonate and stirring for 24 hours, the solid particles were collected by centrifugation at 3000 rpm for 3 minutes, 5 mL of Tris-HCl buffer solution was added to each centrifuge tube...

Embodiment 3

[0029] Dissolve 36 mg of sodium polystyrene sulfonate (PSS) in 15 mL of filtered calcium chloride solution (with a concentration of 0.4M), and add 15 mL of filtered 0.4M sodium carbonate solution to the solution at a rotation speed of 1000 rpm React in the electromagnetic stirrer for 30 seconds, turn off the electromagnetic stirring and let it stand for 25 minutes, then turn on the electromagnetic stirring, stir the reaction solution evenly, add 5 mL to the centrifuge tube, and take 4 tubes in total. Centrifuge the 4 tubes of suspension in a centrifuge with a rotating speed of 3000 rpm for 3 minutes and then wash with deionized water, and repeat the centrifugation-washing operation twice.

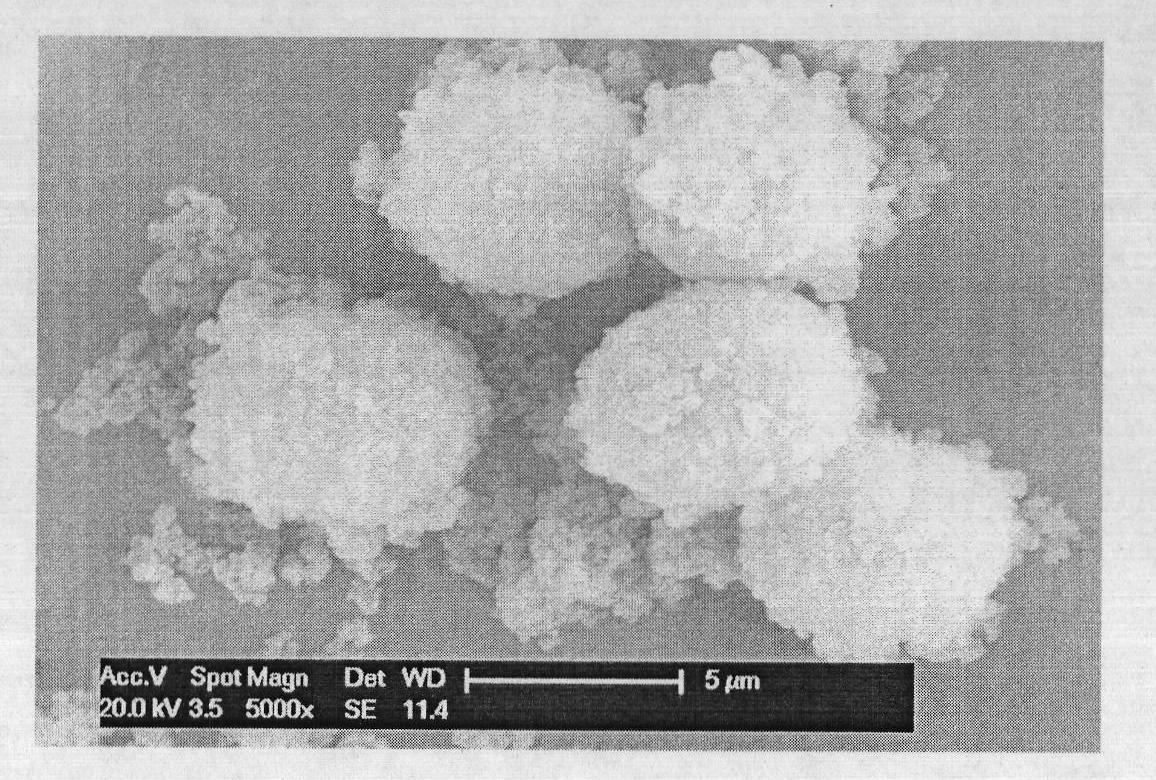

[0030] Prepare 0.1M Tris-HCl buffer solution, adjust its pH to 8.5, and prepare 8mg / mL dopamine solution. After adding the dopamine solution to the washed calcium carbonate and stirring for 8 hours, the solid particles were collected by centrifugation at 3000 rpm for 3 minutes, and 5 mL of Tri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com