Central vertical grounding leading-down method for composite pole tower and pole tower thereof

A composite material and grounding down-conductor technology, which is applied in the configuration of grounding wires, towers, building types, etc., can solve the problems that affect the lightning protection effect of composite material towers, reduce the width of transmission corridors, and affect the anti-fouling of lines. Avoid inconvenient influence, simple structure, the effect of enhancing the insulation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

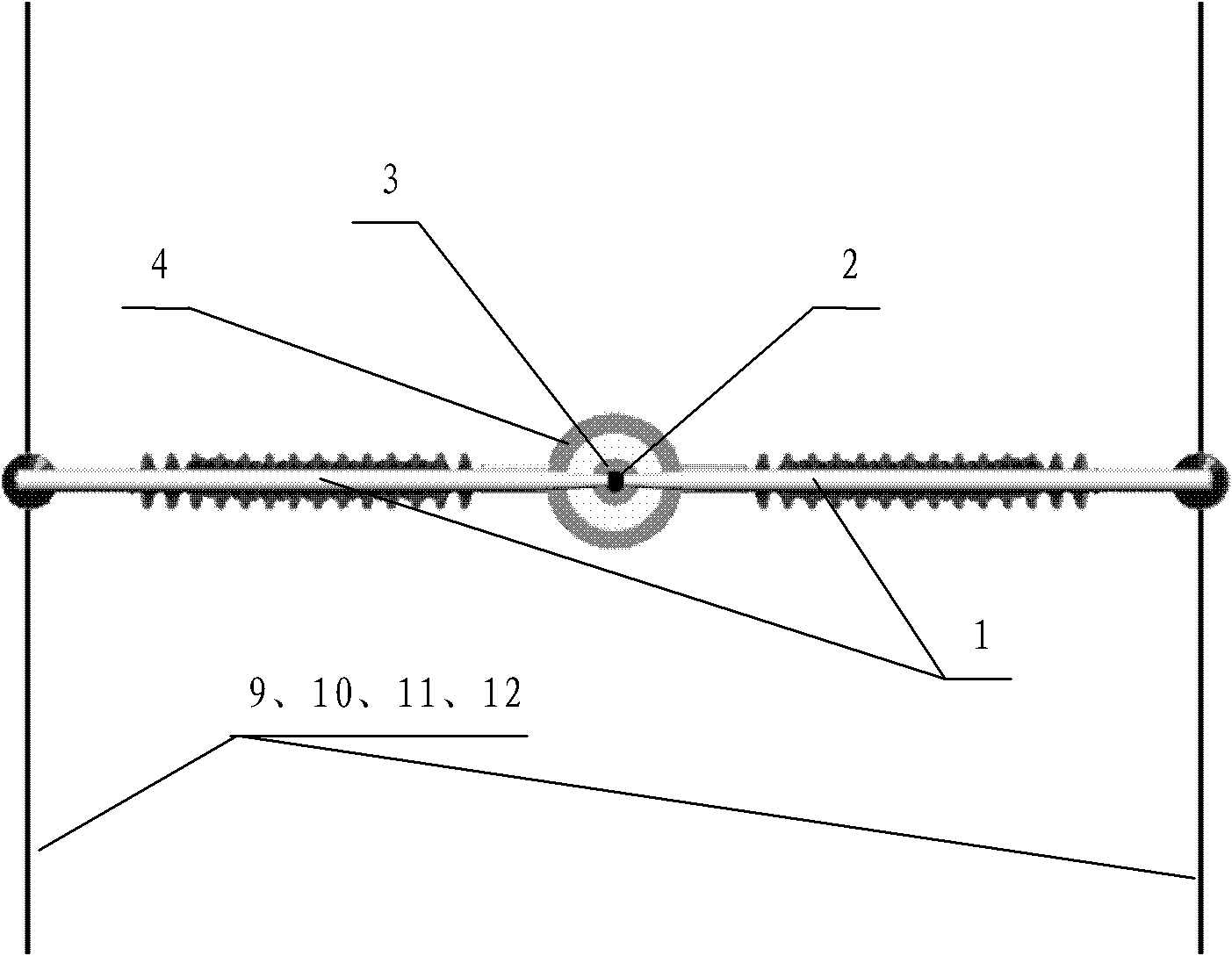

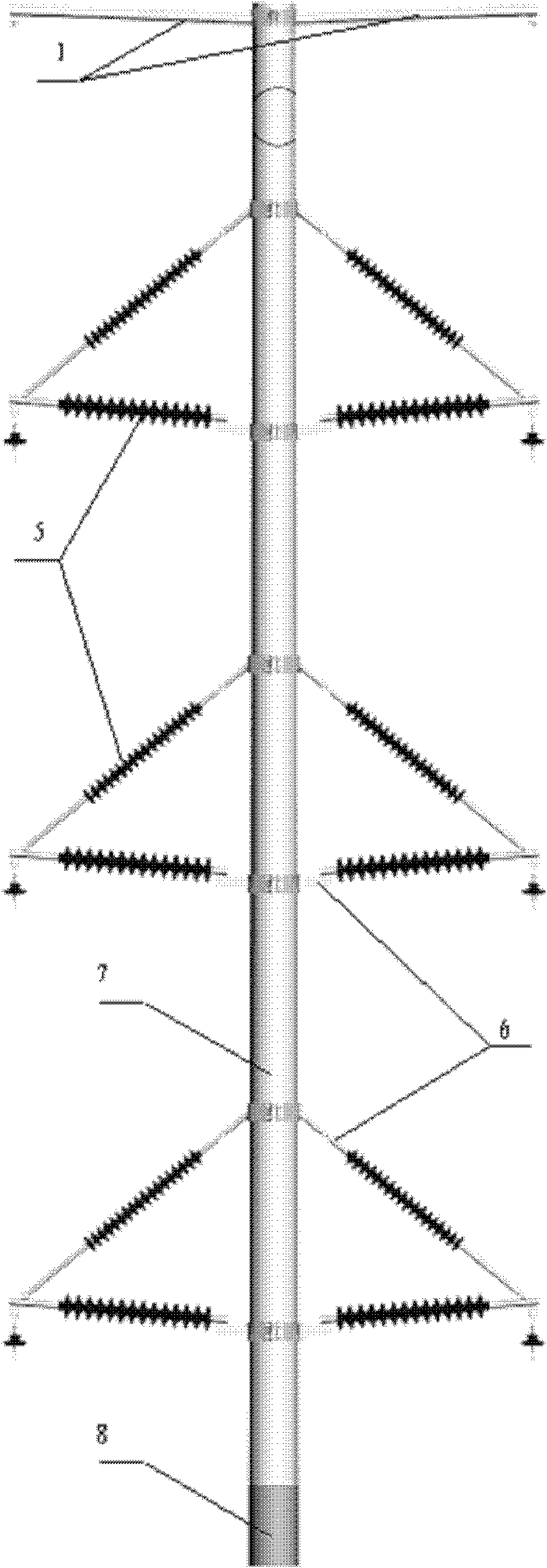

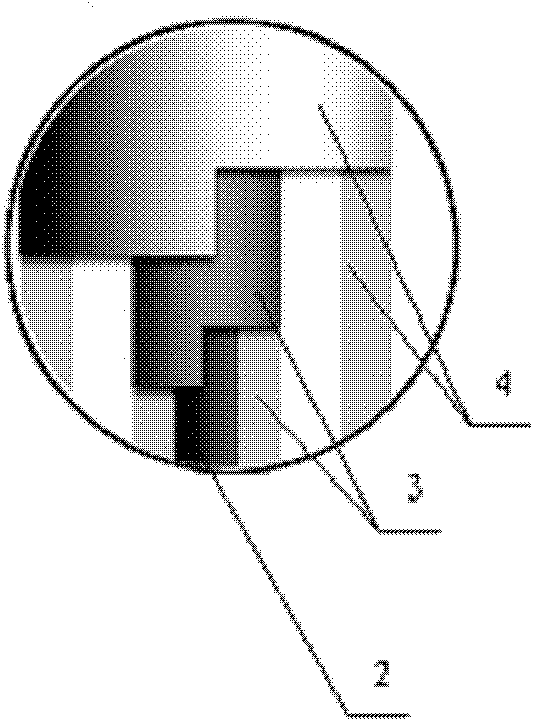

[0028] figure 1 , 2 , Mark description in 4: 1-ground wire crossarm, 2-ground downconductor, 3-ground downconductor insulation cladding, 4-composite material tower wall insulation layer, 5-composite insulator, 6-composite insulator Connecting and supporting parts, 7-tower body part of tower head, 8-tower body lower part, 9-ground wire, 10-upper phase wire, 11-middle phase wire, 12-lower phase wire, 13-flashover point, 14- Flashover point and grounding down conductor electrical connection parts.

[0029] The ground cross arm 1 in the present invention is made of metal material, and the ground down conductor 2 is drawn out from the center of the ground wire cross arm 1, and the ground down conductor 2 is vertically connected to the ground from the center of the composite material tower. Part 8 under the body is a steel pipe, and the grounding downconductor 2 can be directly connected to the steel pipe for grounding.

[0030] Since the tower body part 7 of the tower head of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com