Transparent heat insulation polyvinyl chloride rubberized fabric and preparation method thereof

A technology of polyvinyl chloride and tape, applied in adhesives, film/sheet adhesives, adhesive additives, etc., can solve the problem of high processing cost of process equipment, achieve low processing cost, fast production speed, and save equipment investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

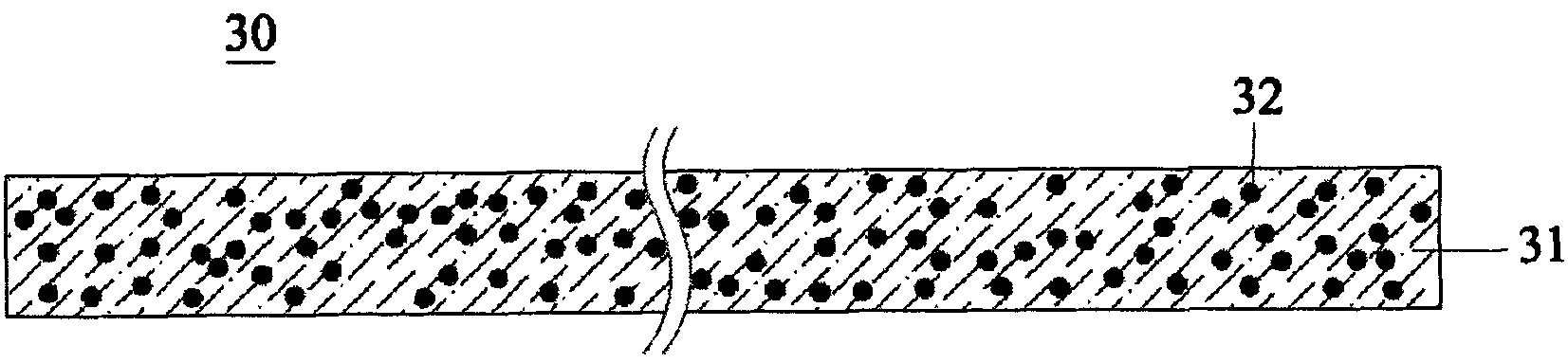

[0059] To produce transparent heat-insulating polyvinyl chloride tape 30 with a thickness of 0.2mm and a softness of 40PHR, the preparation method is as follows:

[0060] According to the specific formula in Table 1, the inorganic heat-insulating particles LaB 6 Raw materials such as additive amount 0.25PHR, modifier 0.81PHR, dispersant 0.17PHR, ultraviolet absorber 0.8PHR, stabilizer 3PHR, plasticizer 40PHR and polyvinyl chloride resin 100PHR were put into the mixer in order (manufactured by HenschelMixer N.P.C, 300L) After mixing evenly, introduce a 10,000-horsepower machine (manufactured by N.P.C, 100L drop-door type) to mix evenly;

[0061] After being gelled by two roller-type roller machines (manufactured by N.P.C, roller speed difference 1:1.15), the temperature of the material is controlled at 150-190°C, and the material is sent to a four-wheel reverse L-shaped calender (manufactured by N.P.C, specification 24″ ×72″), hot-melt adhesive cloth with a thickness of 0.2mm....

Embodiment 2

[0065] According to the specific formula in Table 1, the inorganic heat-insulating particles CeB 6 Addition amount of 0.25 PHR, modifier 0.81 PHR and other raw materials were produced using the method of Example 1 to produce a transparent heat-insulating polyvinyl chloride tape 30 with a thickness of 0.2 mm and a softness of 40 PHR.

[0066] The test results are shown in Table 1, the light transmittance is as high as 70%, and the haze is 2.0%, which shows that the prepared transparent heat-insulating polyvinyl chloride adhesive tape 30 has transparency, and its light transmittance is slightly lower than that of Example 1. Its infrared shielding rate is 64%, second only to Example 1, and its ultraviolet shielding rate is 99%, and the inorganic heat-shielding particles will not precipitate during the processing.

Embodiment 3

[0068] According to the specific formula in Table 1, the raw materials such as the addition amount of inorganic heat-insulating particles ATO 1.8PHR, LaB6 addition amount 0.25PHR, modifier addition amount 6.97PHR, etc., were produced using the method of Example 1 to produce a transparent glass with a thickness of 0.2mm and a softness of 40PHR. Heat insulation polyvinyl chloride tape 30.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Softness | aaaaa | aaaaa |

| Softness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com