Directionally woven flexible camouflage composite material and preparation method thereof

A composite material and flexible technology, used in textiles and papermaking, fiber type, fiber processing, etc., can solve problems such as poor radar wave performance, and achieve the effects of good weather resistance, good camouflage effect, and strong reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] A method for preparing a directional-woven flexible camouflage composite material, comprising the following steps:

[0054] S1. Base fabric layer: Weave conductive and magnetic fibers and non-conductive fibers according to the warp and weft ratio of 3 to 10:1 to form a mesh cloth with a thickness of 0.5 to 3mm;

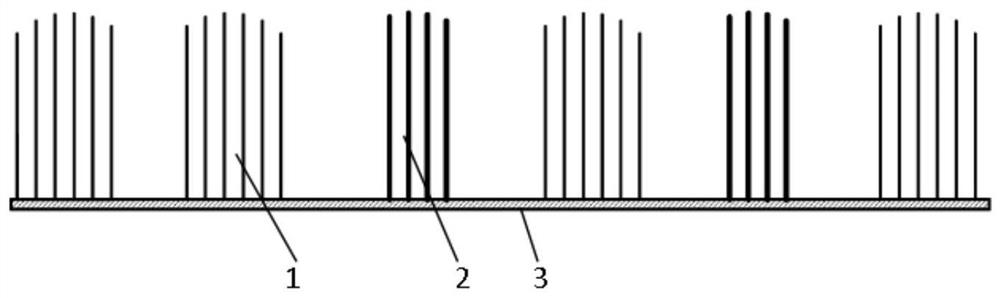

[0055] S2. Plant bionic body: Directly implant conductive fibers and non-conductive fibers on the grid cloth obtained in S1, and form plant bionic body on the base cloth layer;

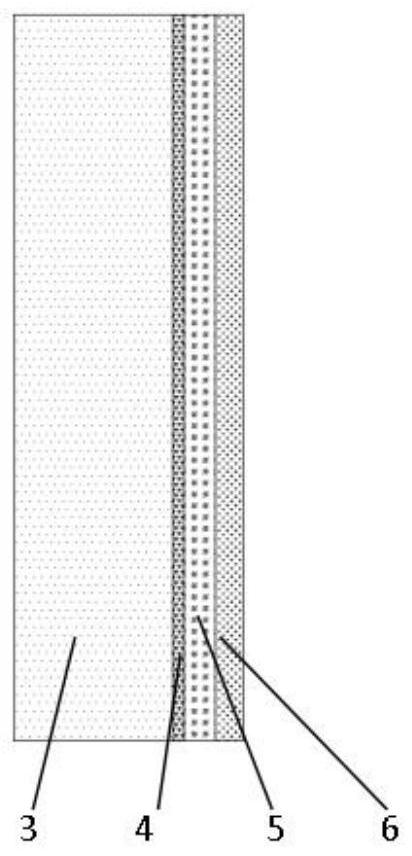

[0056] S3. Infrared camouflage coating spraying: spray the infrared camouflage coating material on the surface of the finished product of S2, and dry and solidify;

[0057] S4. Visible light camouflage coating spraying: the visible light camouflage coating material is sprayed on the surface of the finished product of S3, and dried and cured.

[0058] Specifically: after the fiber fabric sprayed by S4 is dried at room temperature for 48 hours, it can be cut according to the required si...

Embodiment 1

[0064] It includes a base cloth layer 3 composed of mixed fibers, directionally woven conductive and magnetic fibers 2, and non-conductive fibers 3.

[0065] The preparation method of the material comprises the steps of:

[0066] S1: base fabric weaving

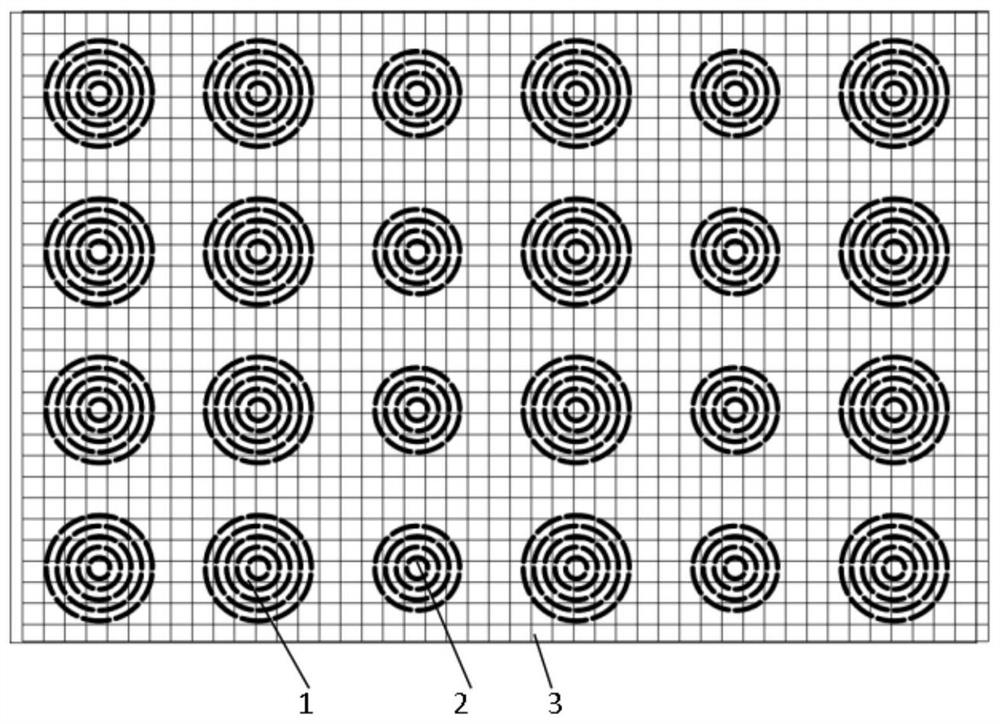

[0067] Such as figure 2 As shown, 6k nickel-plated carbon fiber and 4800Tex glass fiber are woven according to the warp and weft ratio of 5:1 to form a mesh cloth as shown in the figure, and the thickness of the fabric is about 1-2mm.

[0068] S2: Directional fabric weaving (i.e. plant bionics)

[0069] Press 12k nickel-plated carbon fiber cloth with 9600Tex glass fiber figure 1 , 2 The structure is oriented on the surface of the base fabric completed in S1, the arrangement interval is 2 mm, and the length of the oriented fabric is 20-30 mm.

[0070] S3: Infrared camouflage coating material spraying

[0071] The prepared infrared camouflage coating material is sprayed on the surface of the S2 finished product with a hi...

Embodiment 2

[0084] It includes a base cloth layer 3 composed of mixed fibers, directionally woven conductive and magnetic fibers 2, and non-conductive fibers 3.

[0085] The preparation method of the material comprises the steps of:

[0086] S1: base fabric weaving

[0087] Such as figure 2 As shown, 6k copper-plated carbon fiber and 1200D glass fiber are woven according to the warp and weft ratio of 4:1 to form a mesh cloth as shown in the figure, and the thickness of the fabric is about 0.5-1mm.

[0088] S2: Directional Fabric Weaving

[0089] Press 12k nickel-plated carbon fiber cloth with 2400D aramid fiber figure 1 , 2 The structure is oriented weaving on the surface of the base fabric completed in S1, the arrangement interval is 1 mm, and the length of the oriented fabric is 20-25 mm.

[0090] S3: Infrared camouflage coating material spraying

[0091] The prepared infrared camouflage coating material is sprayed on the surface of the S2 finished product with a high-pressure sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com