Method and device for processing high-concentration undegradable waste water by using jet flow membrane bioreactor (MBR)

A high-concentration, refractory technology, applied in the direction of anaerobic digestion, sustainable biological treatment, chemical instruments and methods, etc., can solve the problems that restrict the large-scale and wide application of MBR, the difficulty of cross-flow velocity on the surface, and serious membrane fouling, etc. Achieve excellent and stable effluent quality, accelerate sludge granulation, and improve water flow conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

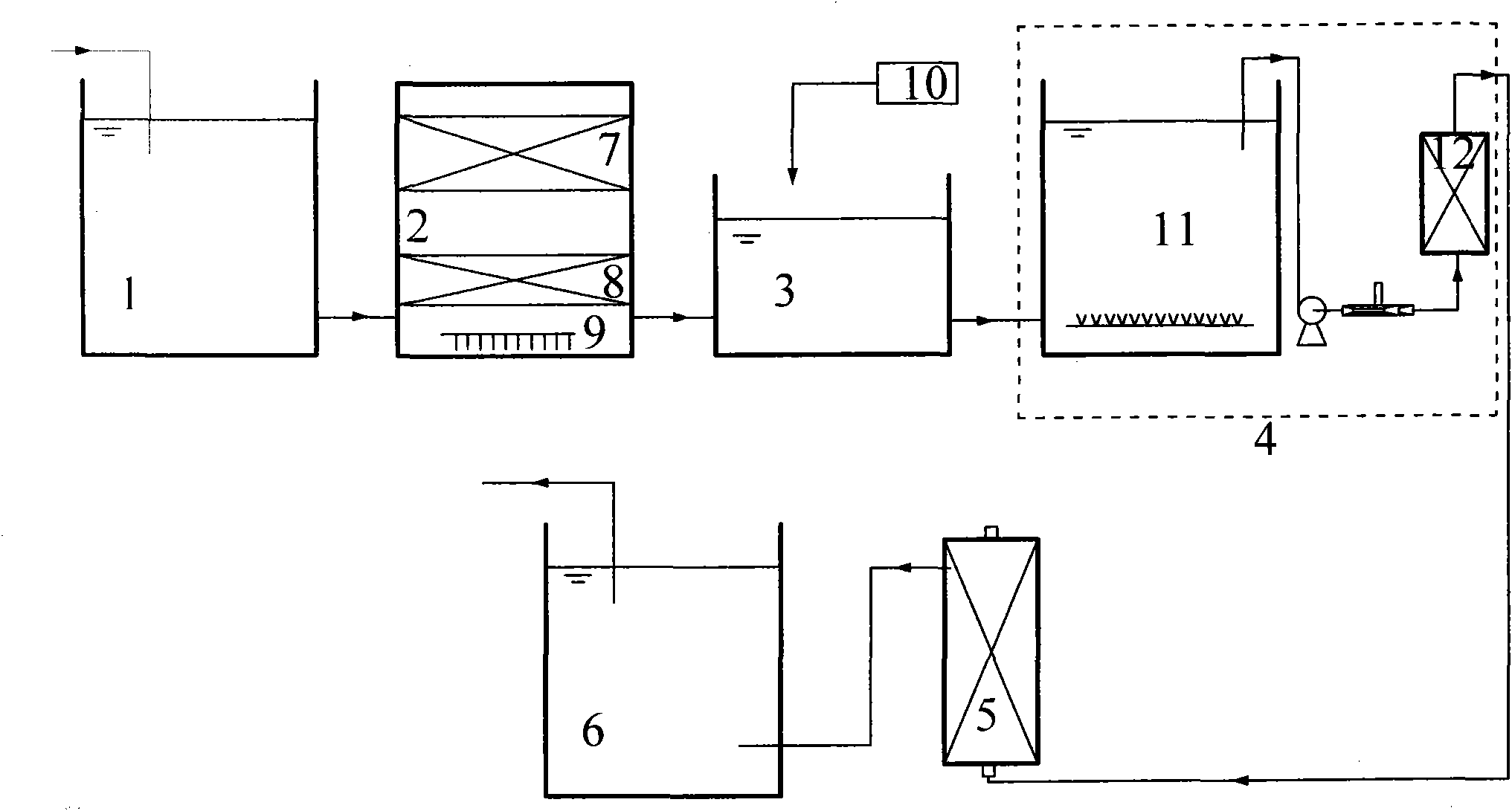

[0028] Example 1: The source of sewage is wastewater from a coking plant, and the water quality condition is: COD Cr The content is 3000~5000mg / L, the BOD content is 700~900mg / L, the total nitrogen is 220mg / L, and the SS is 600mg / L. After compound anaerobic bed-intermediate pool-jet flow MBR-small pore ultrafiltration membrane system-multi-effect oxidation system, the intermediate pool uses O 3 As an oxidant, the ultrafiltration membrane used in the small pore ultrafiltration membrane system has a molecular weight cut-off of 1000 Daltons. Final effluent COD Cr 50mg / L, the total nitrogen concentration is less than 10mg / L, and the chromaticity is less than 15, meeting the industry's first-class discharge standard A;

example 2

[0029] Example 2: The source of sewage is wastewater from a dye chemical factory, and the water quality condition is: CODCr Content 10000~20000mg / L, BOD content 1800~5000mg / L, SS 1200mg / L. After compound anaerobic bed-intermediate pool-jet flow MBR-small pore ultrafiltration membrane system-multiple oxidation system, the intermediate pool uses H 2 o 2 / O 3 As an oxidant, the ultrafiltration membrane used in the small-pore ultrafiltration membrane system has a molecular weight cut-off of 30,000 Daltons. Final effluent COD Cr It is 50mg / L, and the chromaticity is less than 15, reaching the first-class A standard of the industry.

example 3

[0030] Example 3: The sewage water quality condition is: COD Cr The content is 10000~15000mg / L, the BOD content is 1800~3000mg / L, and the SS is 1200mg / L. After compound anaerobic bed-intermediate pool-jet flow MBR-small pore ultrafiltration membrane system-multi-effect oxidation system, the intermediate pool uses H 2 o 2 / Iron carbon is used as an oxidant, and the molecular weight cut-off of the ultrafiltration membrane used in the small pore ultrafiltration membrane system is 5000 Daltons. Final effluent COD Cr It is 50mg / L, and the chromaticity is less than 15, reaching the first-class A standard of the industry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com