Saving type valve low temperature test system

A low-temperature test and test system technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring the acceleration and deceleration rates of fluids, lighting and heating equipment, etc., can solve the problem of increasing the risk of accidents for test personnel and manual intervention. and other problems, to achieve the effect of good thermal insulation effect, reducing test cost and increasing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

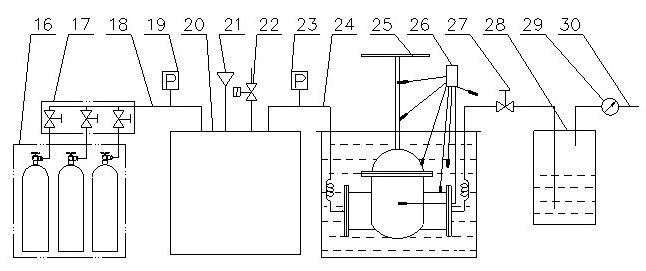

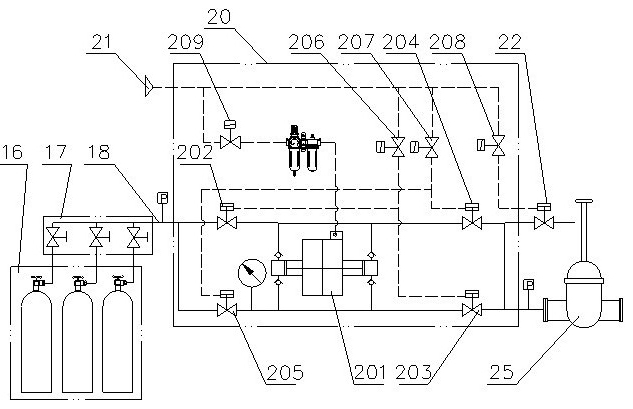

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0028] Cryogenic valve parts whose working temperature is lower than -100°C need cryogenic treatment before finishing, so that the metal phase transformation and deformation of the parts can fully occur. After cryogenically treated components are assembled into finished valves, a low temperature test in a low temperature environment is required to test the sealing and operating performance of the whole machine. Therefore, the present invention is described by taking cryogenic valve parts cryogenic treatment and low temperature test as implementation cases.

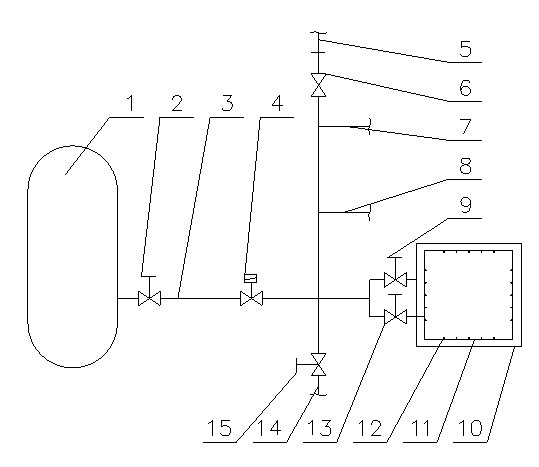

[0029] refer to figure 1 , the low-temperature environment unit in the present invention, its low-temperature storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com