Method for preparing metal composite material bonding interface separated sample

A metal composite material, material testing machine technology, applied in the field of metal composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

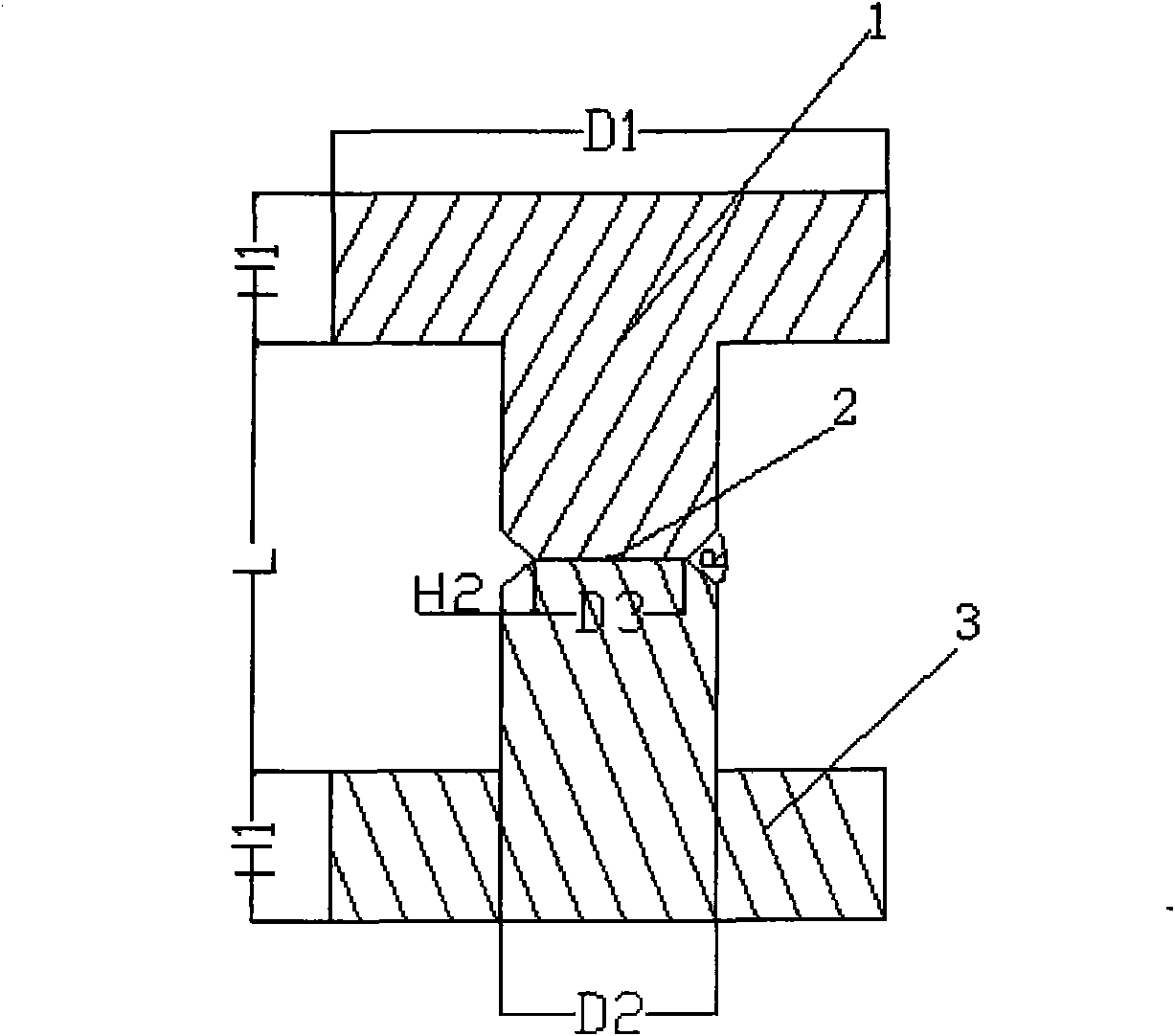

[0021] The material combination is 1060 / TA2 aluminum-titanium bimetallic composite bonded interface separation sample, the thickness of the clad metal 1060 and base metal TA2 of the metal composite is 12mm, processed by lathe figure 1 For the sample shown, D1=25mm, D2=14mm, H1=8mm, D3=6mm, L=8mm, angle R=30° of the V-shaped groove, height H2=4mm, use a 50-ton universal material testing machine to break the test In this way, the binding interface was completely separated, and the useful part was cut out. The morphology, microdomain composition and crystal structure of the binding interface were studied with a JSM-35C scanning electron microscope and a NEOPHOT1 metallographic microscope.

Embodiment 2

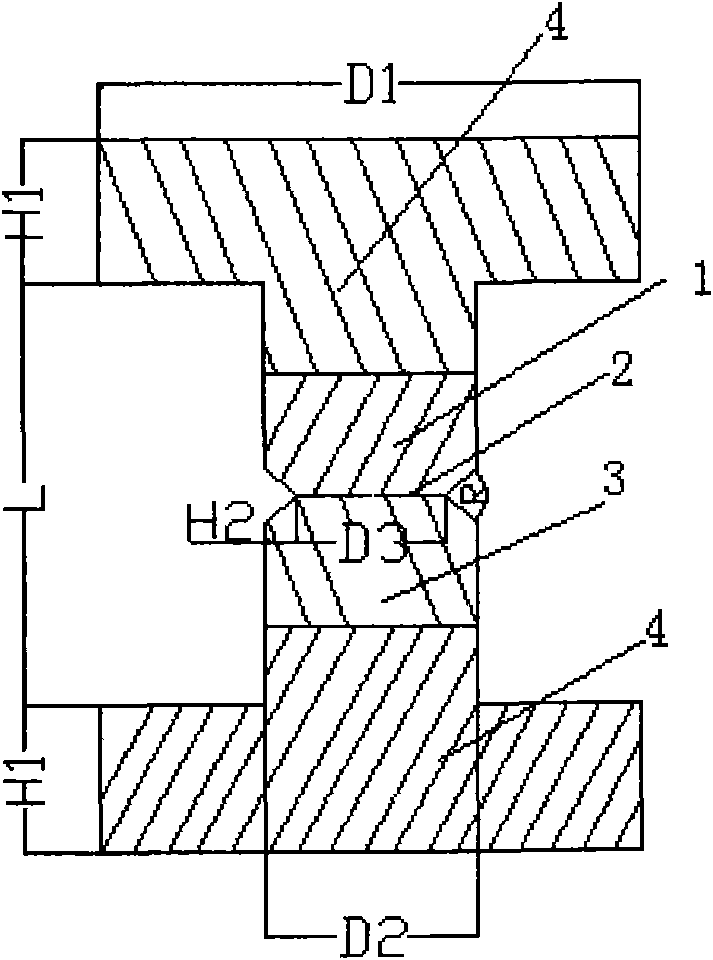

[0023] Prepare the stainless steel-steel bimetallic composite material combined interface separation sample with the material combination of 321 / Q370, the thickness of the clad metal 321 and the base metal Q370 of the metal composite material are 3mm and 6mm respectively, processed by a lathe figure 2 The sample shown is stainless steel 321 with a length of 15mm welded on the multilayer, Q370 with a length of 12mm welded on the base layer, D1=20mm, D2=10mm, H1=5mm, D3=6mm, L=20mm, the angle of the V-shaped groove R=90°, height H2=2mm, the sample was pulled off with a 50-ton universal material testing machine, the bonding interface was completely separated, and useful parts were cut out, and the structure of the bonding interface was studied with a JSM-35C scanning electron microscope and a NEOPHOT1 metallographic microscope Morphology, domain composition, and crystal structure.

Embodiment 3

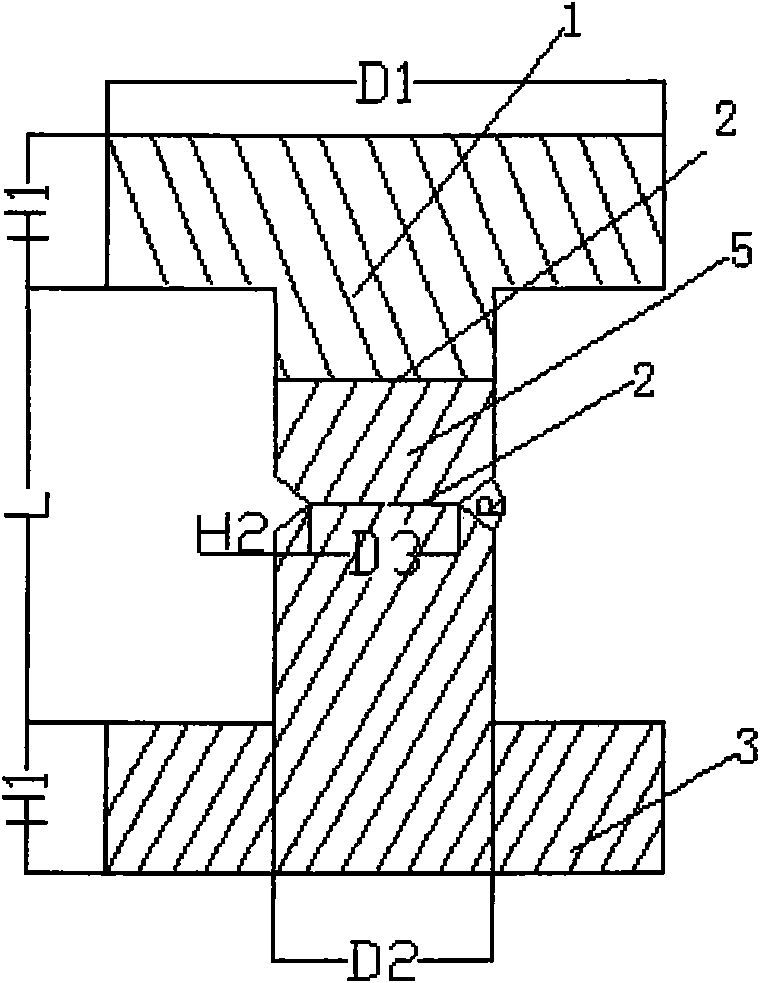

[0025] Prepare the aluminum alloy-aluminum-steel three-layer metal composite material 1060 / CCSB bonded interface separation sample whose material combination is 5083 / 1060 / CCSB. 8mm, 20mm, processed by lathe image 3 The sample shown, D1=15mm, D2=6mm, H1=10mm, D3=4mm, L=20mm, the angle R=45° of the V-shaped groove, the height H2=1mm. In this way, the binding interface was completely separated, and the useful part was cut out. The morphology, microdomain composition and crystal structure of the binding interface were studied with a JSM-35C scanning electron microscope and a NEOPHOT1 metallographic microscope.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com