Method for preparing cuprous oxide composite titanium dioxide nanotube array

A technology of nanotube array and cuprous oxide, which is applied in the field of nanotubes, can solve the problem that the visible light catalytic performance of photocatalysts has not been significantly improved, and achieve the effect of effective degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

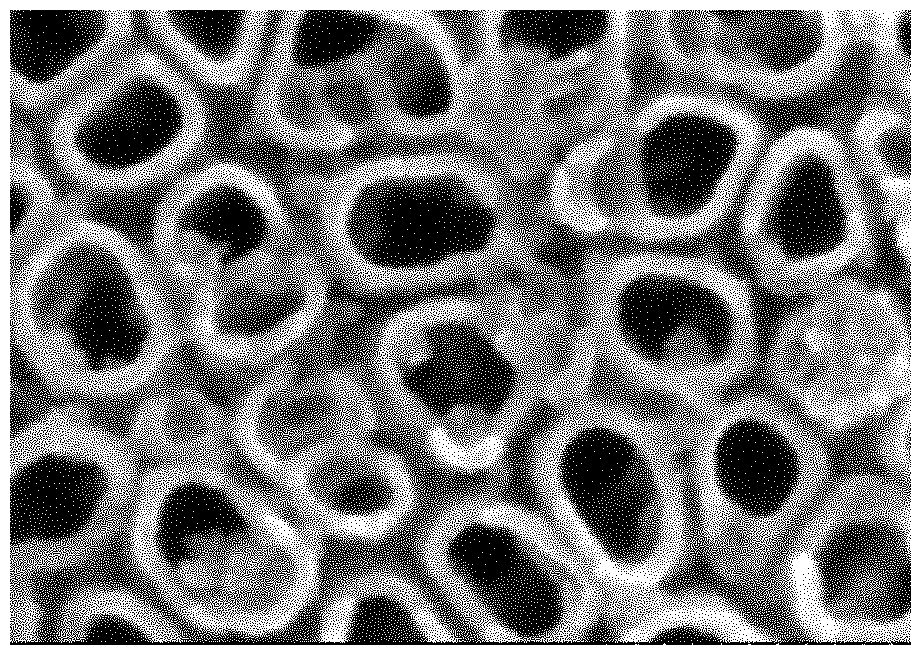

[0020] (1) The base material is a pure titanium plate with a thickness of 2 mm. The surface is polished with metallographic sandpaper until there are no scratches, cleaned with acetone, ethanol and three times of ultrasonic water, and dried in air for use. Prepare an electrolyte solution of 0.1wt% HF, use platinum as the counter electrode at room temperature, perform electrochemical anodic oxidation at 20V for 1h, and calcinate at 400°C for 0.5h to obtain ordered Ti0 on the surface of the titanium plate 2 The nanotube array film layer has an inner diameter of 80-90nm and a film thickness of about 500nm.

[0021] (2) Using an ultrasonic method, a cuprous oxide-composite TiO2 nanotube array is prepared. 0.025mol CuAc 2 Dissolve in 30ml of ethanol, then add 0.06mmol of PVP to it, after the solution is uniformly dispersed, put the film layer obtained in step 1, put all the solution in a 100°C water bath, then add 0.38mol of glucose and 0.60mol of NaOH , after ultrasonication for...

Embodiment 2

[0024] (1) TiO 2 The preparation of the nanotube array film layer is the same as in Example 1.

[0025] (2) Using ultrasonic method to prepare composite cuprous oxide nanoparticles modified TiO 2 Nanotube Array Photocatalysts. 0.005mol CuAc 2 Dissolve in 40ml of ethanol, then add 0.02mol of PVP to it, after the solution is uniformly dispersed, put the film layer obtained in step 1, put all the solution in a 100°C water bath, then add 0.26mol of glucose and 0.40mol of NaOH , after ultrasonication for 60 min, the sample was taken out and vacuum-dried at 100° C. for 2 h to prepare a cuprous oxide composite TiO2 nanotube array photocatalyst.

[0026] (3) TiO compounded with cuprous oxide 2 The test of the apparent rate constant k of the nanotube array photocatalyst for the visible light catalytic degradation of rhodamine B is the same as in Example 1, and the results are shown in Table 1.

Embodiment 3

[0028] (1) TiO 2 The preparation of the nanotube array film layer is the same as in Example 1.

[0029] (2) Using ultrasonic method to prepare composite cuprous oxide nanoparticles modified TiO 2 Nanotube Array Photocatalysts. 0.05mol CuAc 2 Dissolve in 50ml of ethanol, then add 0.04mmol of PVP to it, after the solution is uniformly dispersed, put the film layer obtained in step 1, put all the solution in a 100°C water bath, then add 0.32mol of glucose and 0.18mol of NaOH , after ultrasonication for 30min, the sample was taken out and vacuum-dried at 120°C for 2h to obtain the TiO composite cuprous oxide nanoparticles. 2 Nanotube Array Photocatalysts.

[0030] (3) TiO compounded with cuprous oxide 2 The test of the apparent rate constant k of the nanotube array photocatalyst for the visible light catalytic degradation of rhodamine B is the same as in Example 1, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com