Method for preparing microcystin-LR

A microcystin, semi-preparation technology, applied in the direction of algae/bryopeptide, peptide source, etc., can solve the problem of immature pure isomers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

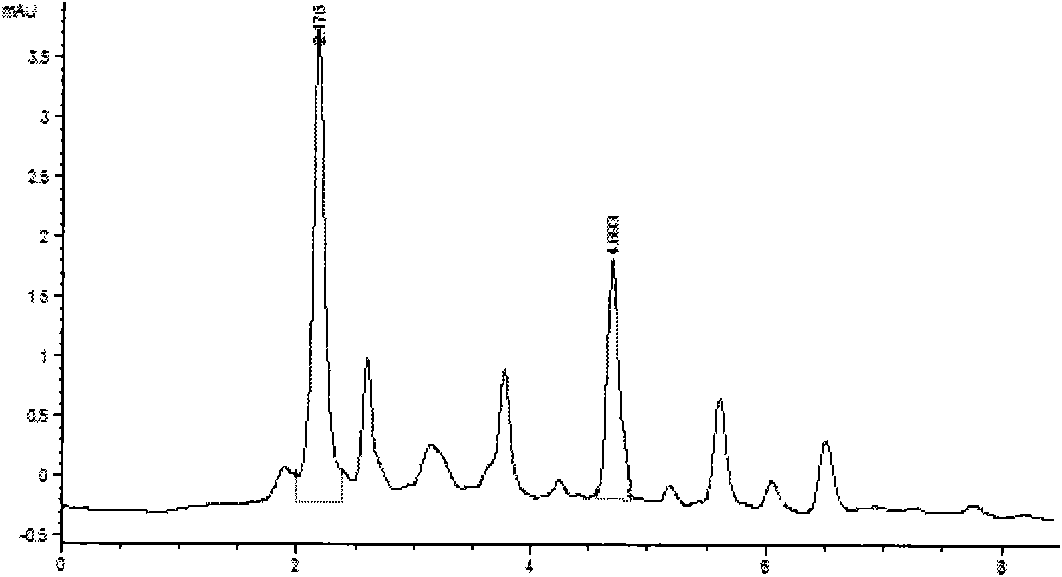

[0013] In a 150 mL Erlenmeyer flask, add 2 g of dry cyanobacteria powder collected from Dianchi Lake and 40 mL of 65% (v / v) acetonitrile / water solution, stir magnetically for 60 min at room temperature, oscillate ultrasonically for 20 min, and freeze in liquid nitrogen for 10 min. After thawing, centrifuge at 10,000 rpm for 10 min, and remove the supernatant. The residue was extracted twice using the above steps, and the supernatants were combined. Filtrate with a 0.45 μm microfiltration membrane to obtain crude microcystin. Preliminary purification of the crude product by solid-phase extraction: activate the solid-phase extraction column with 10mL 100% methanol and 10mL ultrapure water successively, and flow the crude extract through the solid-phase extraction column at a flow rate of 1mL / min for concentration and enrichment, 5mL 40 % (v / v) methanol / water solution was rinsed to remove impurities, 10mL 70% (v / v) acetonitrile / water solution was eluted and sample components wer...

Embodiment 2

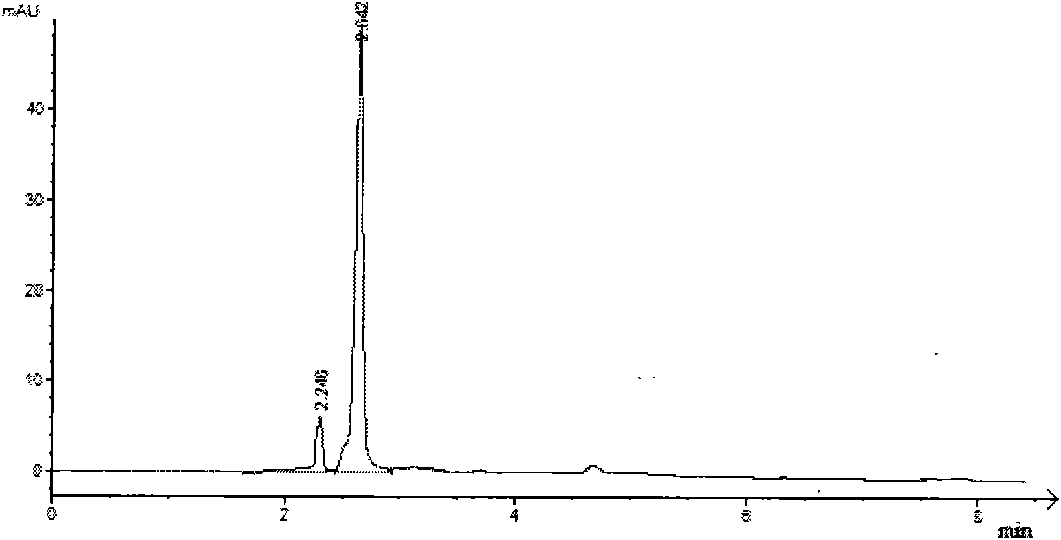

[0015] In a 150 mL Erlenmeyer flask, add 4 g of dry cyanobacteria powder collected from Dianchi Lake and 100 mL of 65% (v / v) acetonitrile / water solution, stir magnetically for 90 min at room temperature, oscillate ultrasonically for 20 min, and freeze in liquid nitrogen for 10 min. After thawing, centrifuge at 10,000 rpm for 10 min, and remove the supernatant. The residue was extracted twice using the above steps, and the supernatants were combined. Filtrate with a 0.45 μm microfiltration membrane to obtain crude microcystin. Preliminary purification of the crude product by solid-phase extraction: sequentially activate the solid-phase extraction column with 10mL 100% methanol and 10mL ultrapure water, and flow the crude extract through the solid-phase extraction column at a flow rate of 1mL / min for concentration and enrichment, 5mL40% (v / v) methanol / water solution was rinsed to remove impurities, 10mL 80% (v / v) acetonitrile / water solution was eluted and sample components were...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com