Method for processing garbage leachate by using microbial fuel cell

A landfill leachate and fuel cell technology, which is applied in biochemical fuel cells, biological water/sewage treatment, chemical instruments and methods, etc., to achieve the effects of easy implementation, small power generation, and small treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

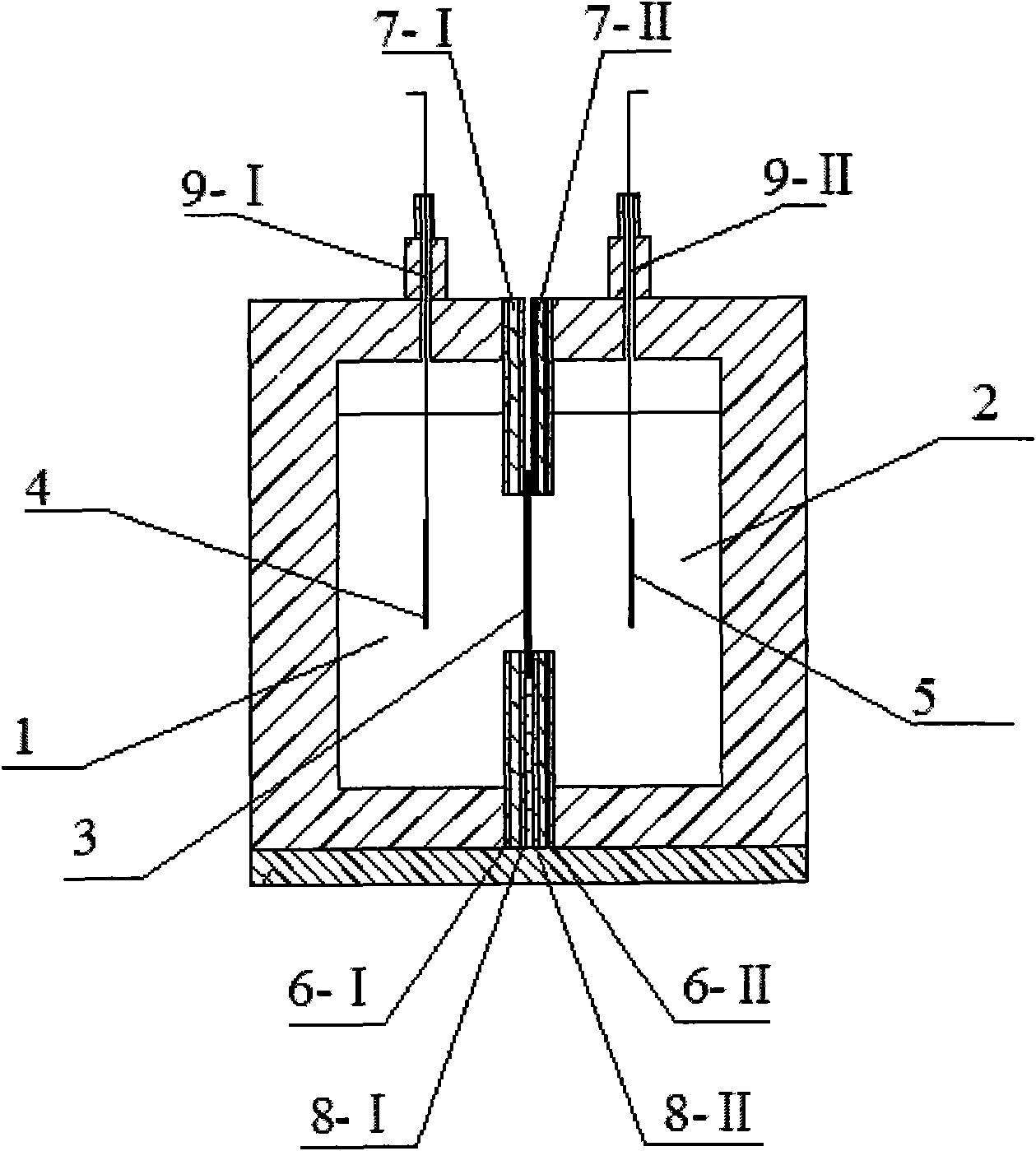

[0020] A method for treating landfill leachate using a microbial fuel cell, the microbial fuel cell has a structure such as figure 1 As shown, it is composed of anode chamber 1, cathode chamber 2, proton membrane 3, anode 4, cathode 5, silica gel gasket 6-I, II, backing plate 7-I, II and silica gel gasket 8-I, II, the anode chamber 1 and the cathode chamber 2 are both head-type cylinder structures, the cylinder part is the reaction chamber, the upper part of the cylinder of the anode chamber 1 and the cathode chamber 2 are respectively provided with electrode jacks 9-I, II, the anode reaction chamber and The anode 4 and the cathode 5 are respectively arranged in the cathode reaction chamber and are respectively sealed and drawn out from the electrode jacks 9-I and II through wires. The proton membrane 3 is square, which is sandwiched between two silica gel gaskets 8-I and II and passed through two A backing plate 7-I, II is fixed, and the center of silica gel spacer 8-I, II an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com