Grid type membrane module with glass fiber braided tube

A technology of glass fiber and braided tubes, which is applied in the field of membrane separation technology. It can solve the problems of sludge layer clogging between membrane filaments, uneven distribution of membrane flux, and low strength of membrane modules, so as to reduce membrane pollution and reduce maintenance costs. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

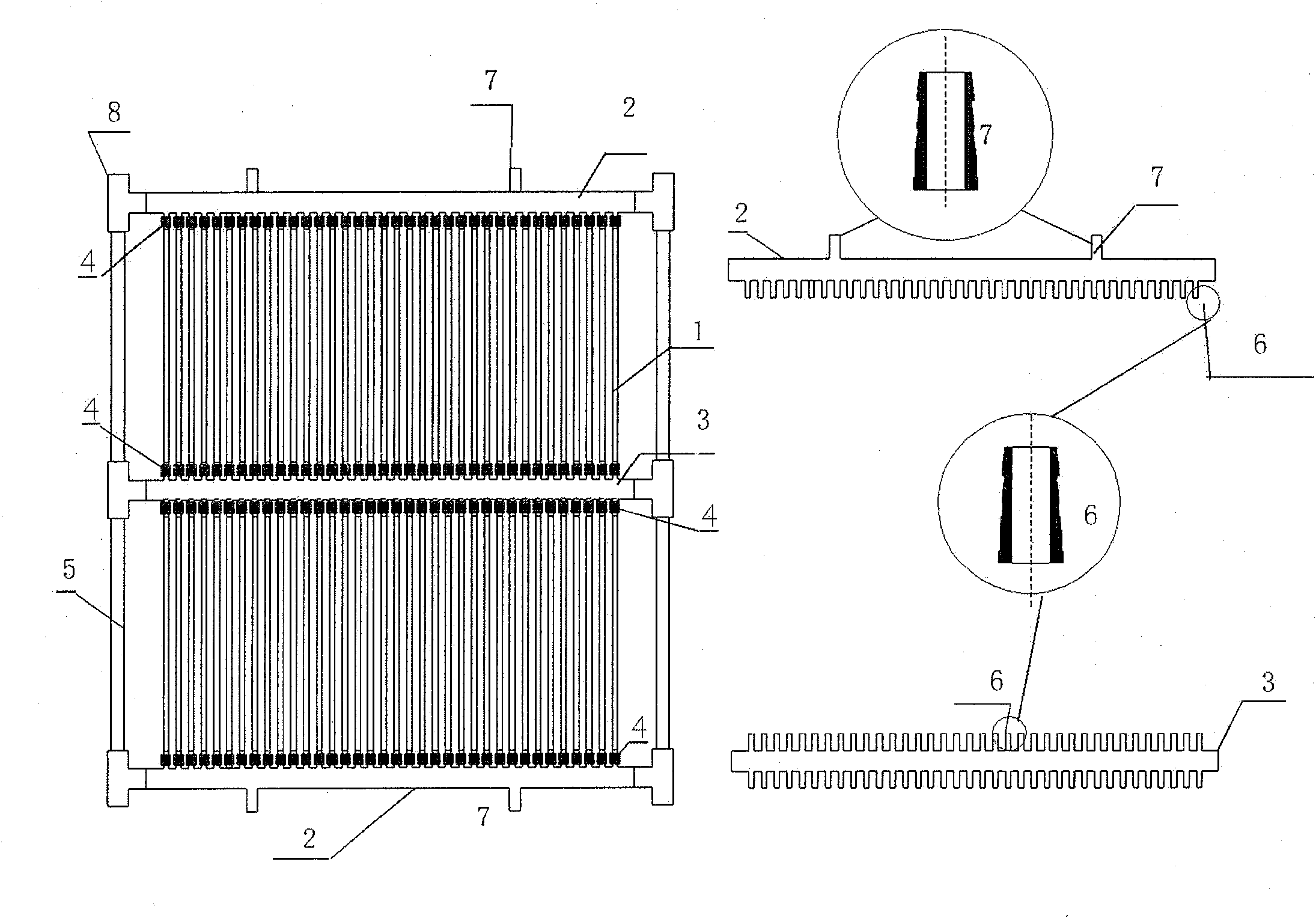

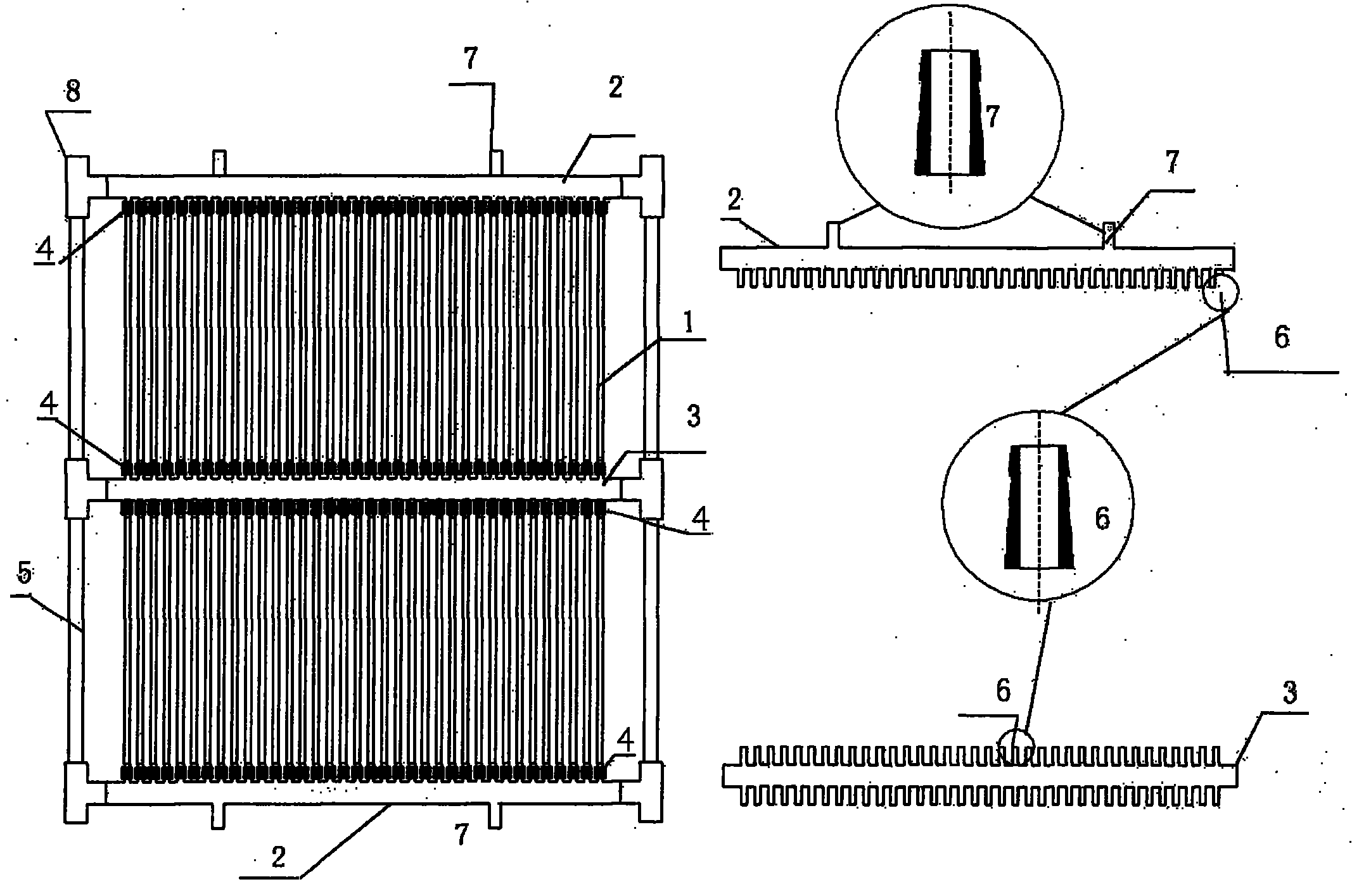

[0008] (1) Make the water collection pipes at both ends and the middle water collection pipe respectively, and use the film-coated or cured glass fiber braided pipe as the membrane substrate. For the configuration of the membrane module, see figure 1 ;

[0009] (2) Will contain COD 200 ~ 500mg / L, BOD 5 100-300mg / L, ammonia nitrogen 50-160mg / L, SS 20-50mg / L domestic sewage, enter the activated sludge glass fiber braided tube membrane bioreactor for treatment, and the membrane unit adopts the glass fiber braided tube of the present invention Grid-type membrane module, under the condition of air-water ratio of 20:1 (the general design value is 15-30:1), the blowing volume is 5m 3 / hr, temperature 12~29℃, pH 6.5~8.0, operating pressure 16~20kPa, stable operation for 6 months. The COD value of the system effluent varies between 30 and 100mg / L, generally stable below 50mg / L, the BOD5 value below 10mg / L, the ammonia nitrogen below 10mg / L, the turbidity below 5NUT, and the effluent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com