Tea mechanization and clean production line

A cleaning and production line technology, applied in the field of cleaning production lines and tea mechanization, can solve the problems of charcoal resource environment and pollution, uneven quality, large manpower, etc., and achieve the effect of being conducive to maintenance and replacement and avoiding secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

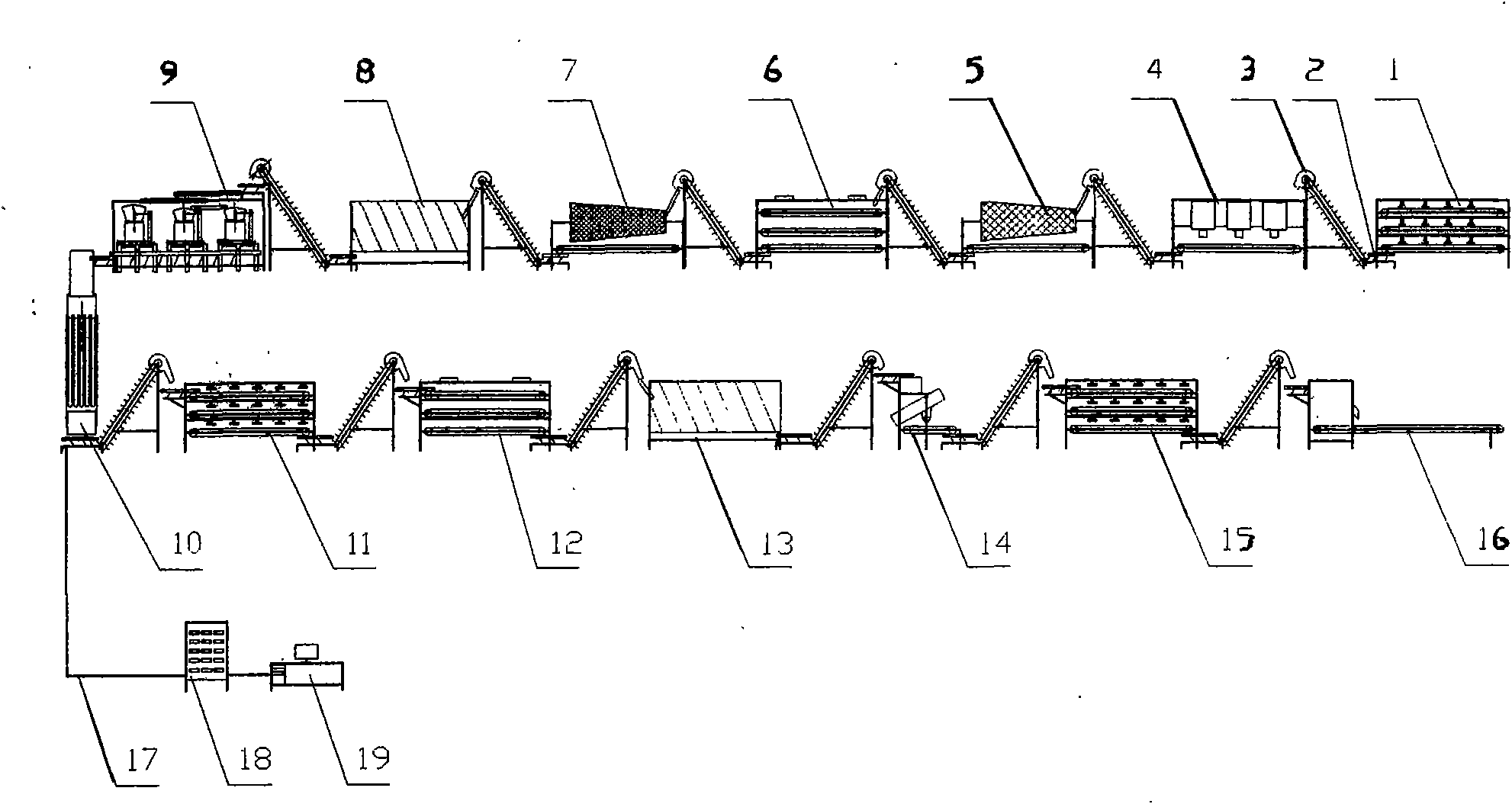

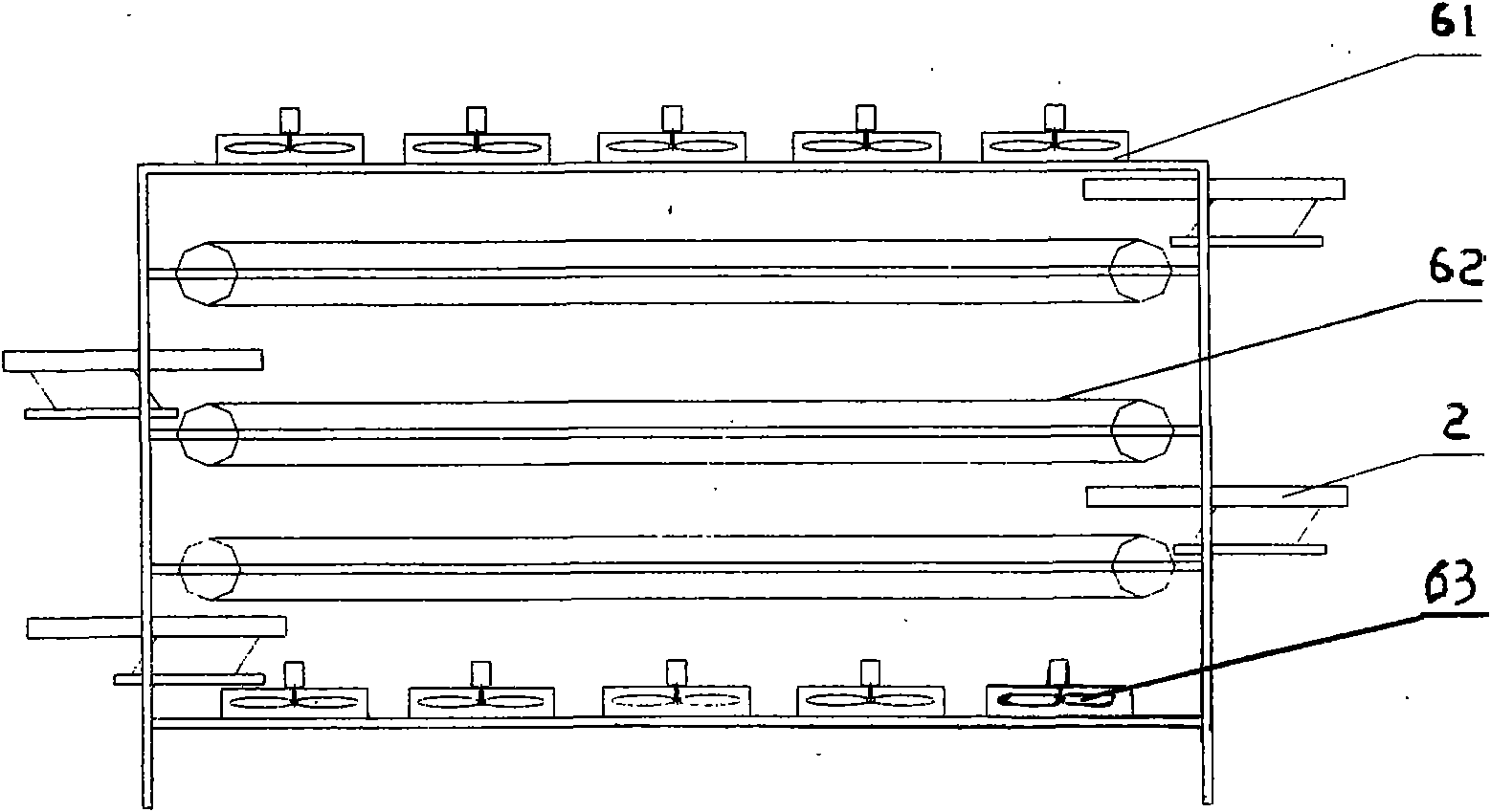

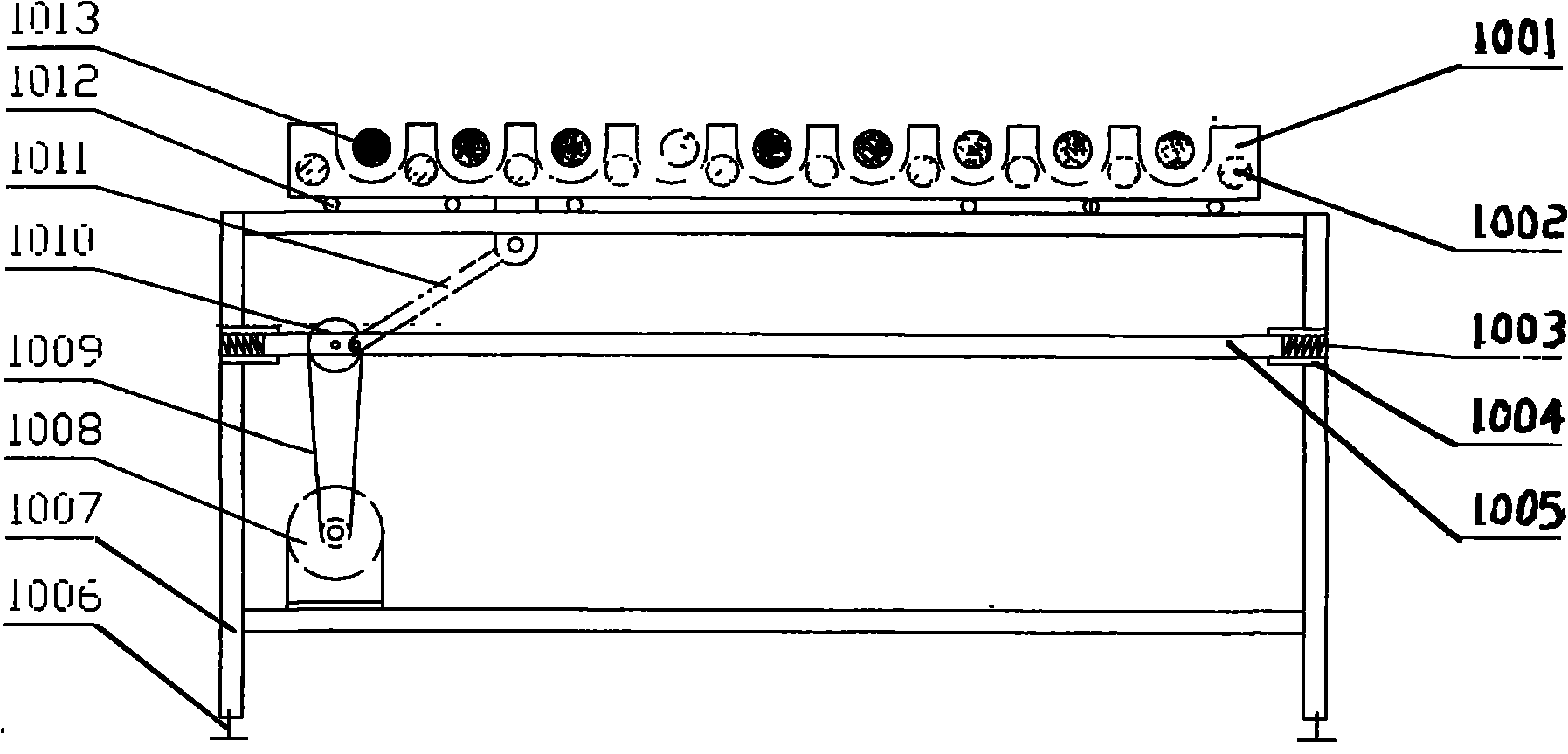

[0014] Such as figure 1 Shown, a kind of tea mechanized, cleaning production line, comprises by cleaning machine 1, dehydrator 4, classifier 5, spreading green machine 6, shaking green machine 7, drum fixing machine 8, kneading machine 9, multi-groove pot type continuous The various process equipments composed of strip machine 10, low-temperature far-infrared roaster 11, cooling machine 12, brilliance pot machine 13, tea color sorter 14, high-temperature far-infrared roaster 15 and tea packaging machine 16 are composed of conveyors and hoisting machines. The feeding mechanism that machine 3 constitutes and the control mechanism that is constituted by microcomputer 19 and central control cabinet 18. The above-mentioned adjacent process equipments are respectively connected in turn by conveyors and elevators, wherein the conveyor belt is installed below the discharge port of the previous process equipment, and the elevator is installed at the discharge port of the conveyor belt....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com