High-temperature superconducting motor

A high-temperature superconducting and electric motor technology, applied in the direction of winding conductive materials, electric components, electrical components, etc., can solve the problems of motor structure, performance and efficiency, increase the air gap distance, affect the performance of the motor, etc., to reduce loss, self- The effect of small field leakage flux and high current carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

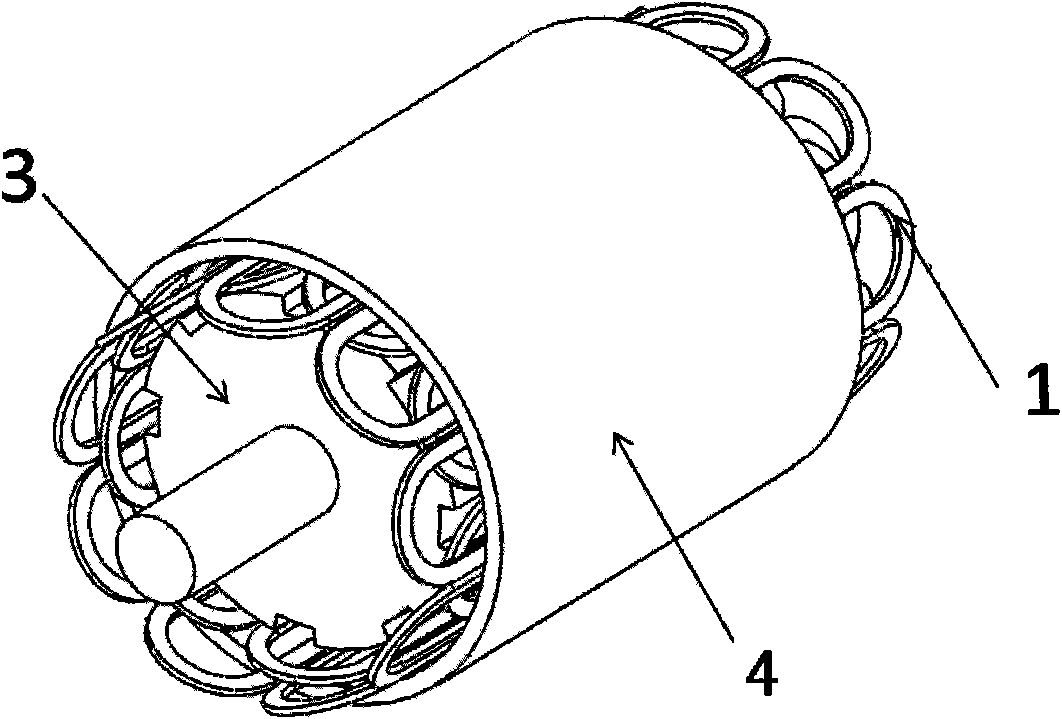

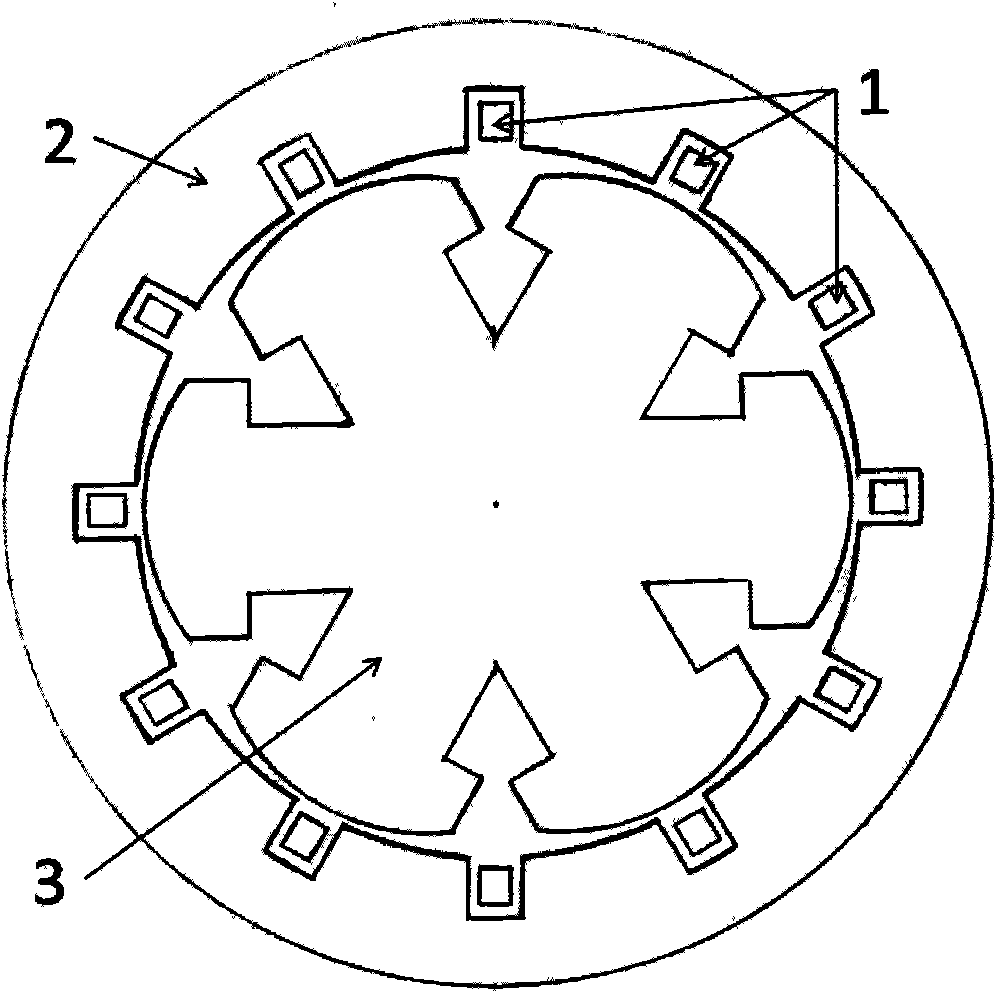

[0053] In this embodiment, the heat-insulating Dewar 4 as the heat-insulating layer is in the outermost layer, the rotor 3 is a DC excitation winding wound with a high-temperature superconducting armature winding 1, and the stator core 2 is a wind-driven generator wound with a high-temperature superconducting AC armature winding . The specific structure is a centralized three-phase winding structure with 8 poles and 9 slots. The stator core 2 is made of silicon steel sheets and has nine stator slots, each of which has two conductor sides of different coils placed in parallel. The notch is fitted with a magnetic slot wedge structure. The pitch of each superconducting coil is 1, that is, a coil spans only one tooth, and the coil shape of the high-temperature superconducting armature winding 1 is a racetrack shape. The main magnetic flux of the air gap in the motor is generated by the DC excitation coil of the high temperature superconducting armature winding 1 on the rotor 3 ....

Embodiment 2

[0055] In this embodiment, the heat-insulating Dewar 4 as the heat-insulating layer is on the outermost layer, the rotor 3 is a permanent magnet, and the stator core 2 is a generator wound with high-temperature superconducting AC armature windings. A 10Hz alternating current is passed through the high temperature superconducting alternating current armature winding. The specific structure is a centralized three-phase winding structure with 8 poles and 9 slots, such as Figure 10 shown. The stator iron core 2 is made of silicon steel sheet and is divided into two parts: stator teeth 14 and stator yoke 15. There are nine stator slots 13 in total, and the conductor sides of two different coils are placed in each stator slot and placed in parallel. The notches of the stator slots are fitted with magnetic slot wedge structures. The span of each high-temperature superconducting coil is 1, that is, a coil spans only one tooth. The shape of the high temperature superconducting coil...

Embodiment 3

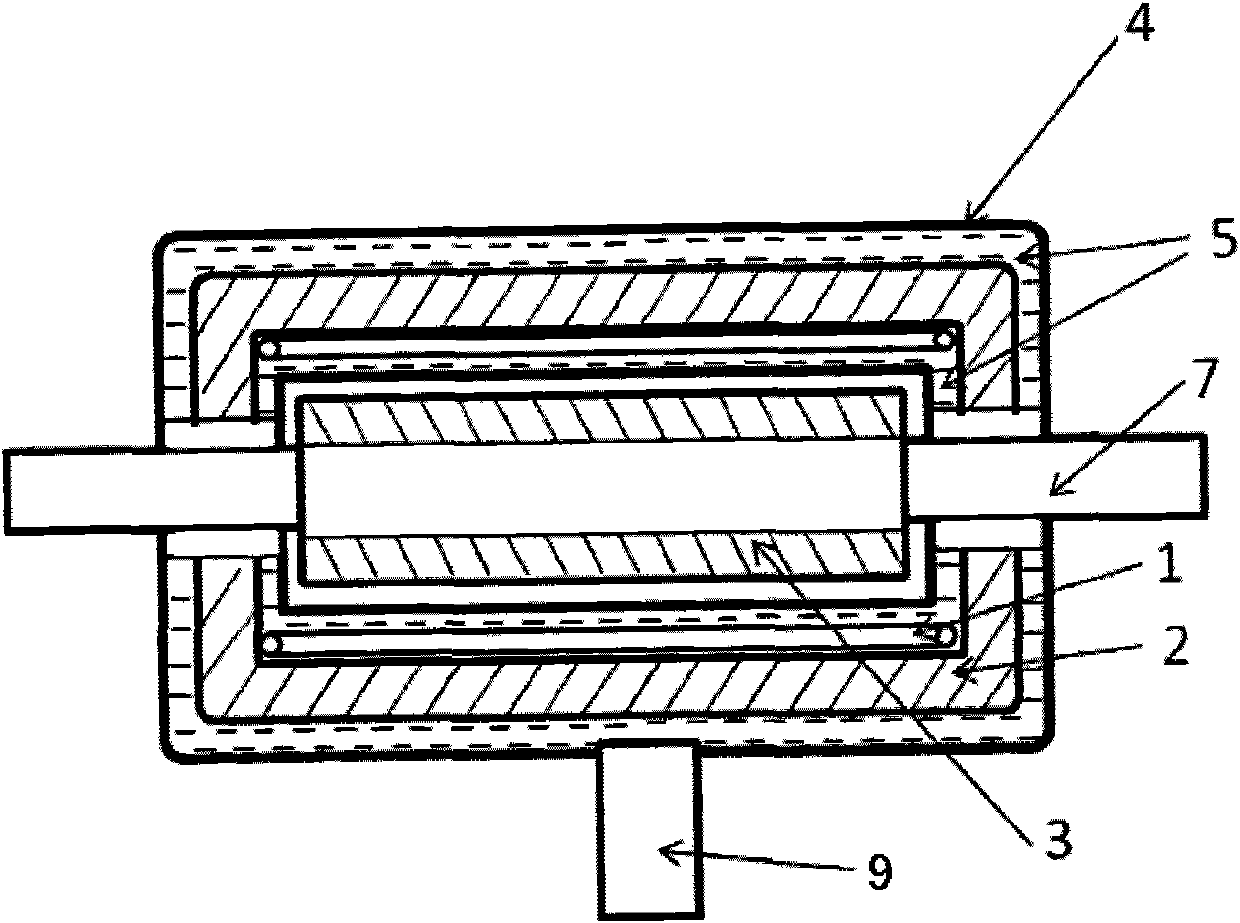

[0057] In this embodiment, the rotor 3 is a permanent magnet, and the stator core 2 is a generator wound with high-temperature superconducting AC armature windings. Its basic structure is as follows Figure 11 shown. The heat-insulating Dewar 4 is located in the outermost layer; the high-temperature superconducting armature winding 1 is located in the interior of the rotor 3; the interior of the stator core 2 is provided with a low-temperature refrigerant 5, which can be directly introduced into a cryogenic liquid (including liquid helium, liquid neon, liquid hydrogen) , liquid nitrogen), can also be connected with refrigeration system; Permanent magnet block 16 is positioned at the outside of air gap 12, can adopt NdFeB permanent magnet, or samarium cobalt permanent magnet, or ferrite permanent magnet, or AlNi Cobalt permanent magnets can also be magnetized YBCO high-temperature superconducting bulk materials.

[0058] The characteristic of this example is that when the gene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal conductivity at room temperature | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com