Fiber grating-based transformer internal temperature detection system

A fiber grating and internal temperature technology, which is applied in the direction of physical/chemical change thermometers, thermometers, instruments, etc., can solve the problem of large positioning errors of transformers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

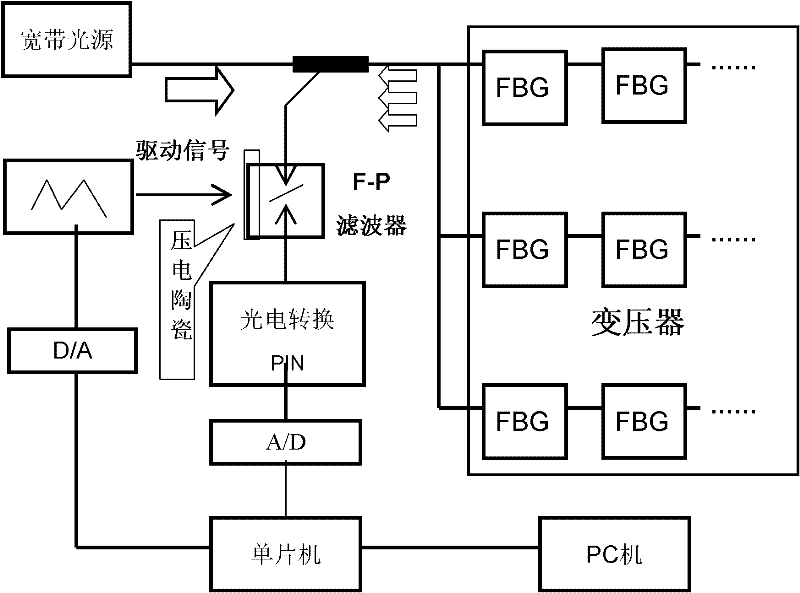

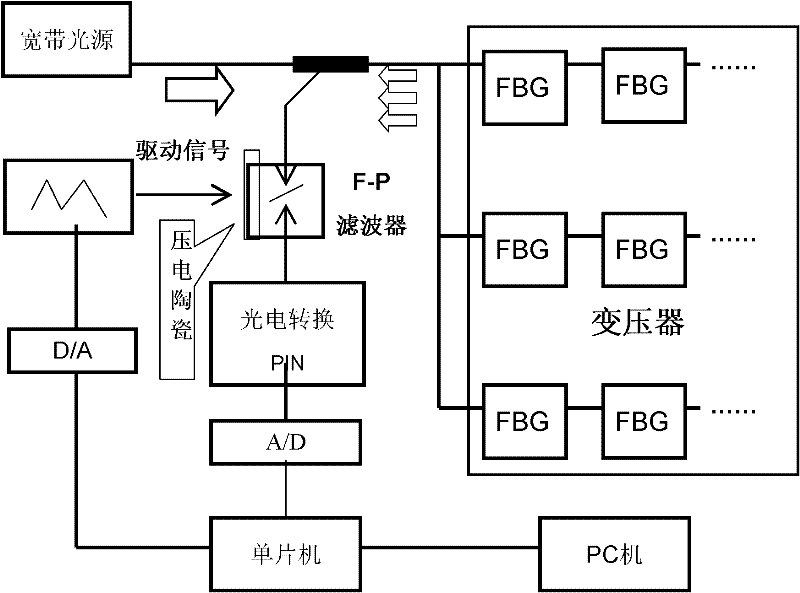

[0015] The working principle of the system of the present invention is as follows: figure 1 shown. The principle of use is as follows. The broadband light source is reflected by the Bragg grating into narrow-band light, and its reflection wavelength is determined by the grating period. When the external temperature changes or the strain acts on the grating, the fiber grating period and effective refractive index change, and then the reflection wavelength When the change occurs, the demodulator converts the wavelength-coded sensor signal into a digital signal and sends it to the computer for calculation and processing. After the transformer works for a period of time, the temperature of the transformer winding will rise, so that the reflection wavelength of the fiber grating attached to the winding will change. The wavelength of the F-P cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com