Double buckling-restrained steel brace for continuous restraint on yield thin wall surface

A steel support and thin-wall technology, applied in the field of double anti-buckling steel support, can solve the problems of poor reliability and durability, difficulty in connection and installation of engineering construction, unstable energy consumption performance, etc., so as to improve work reliability and reduce The effect of low maintenance cost and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

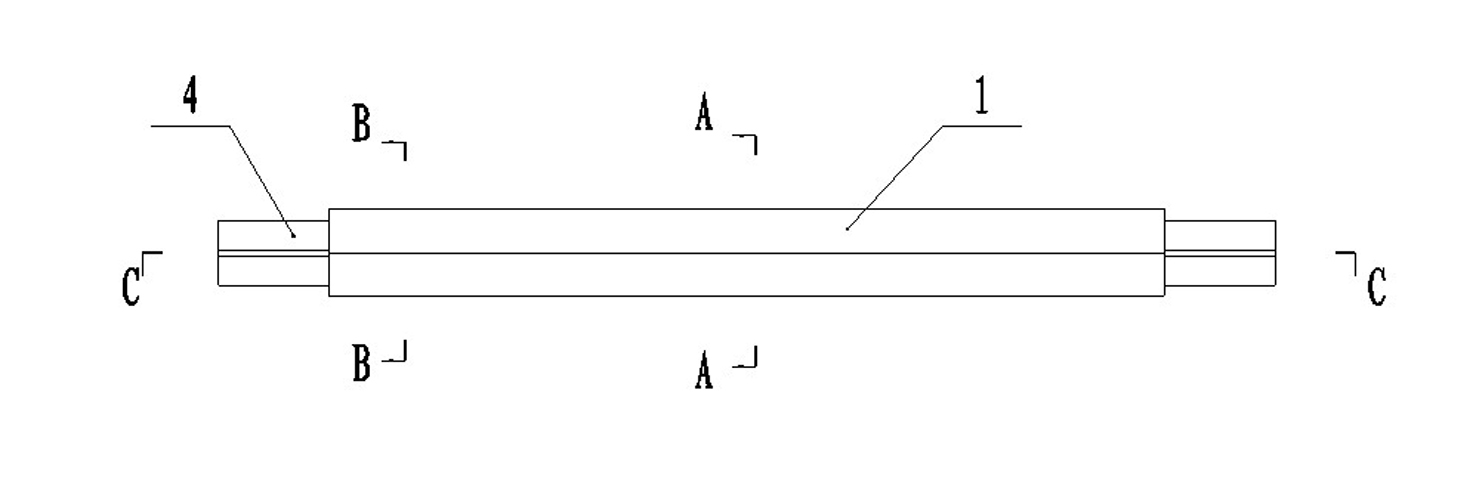

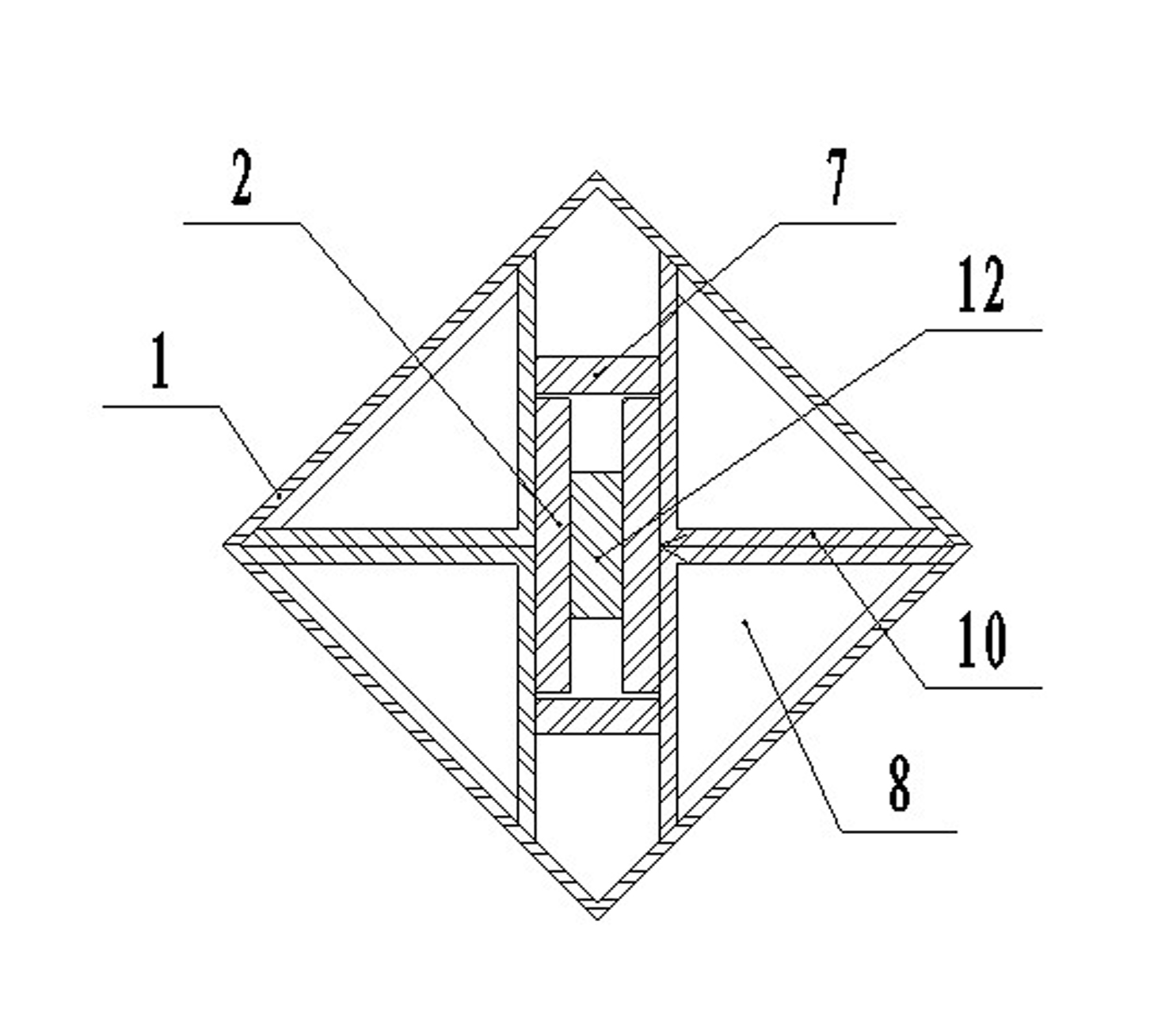

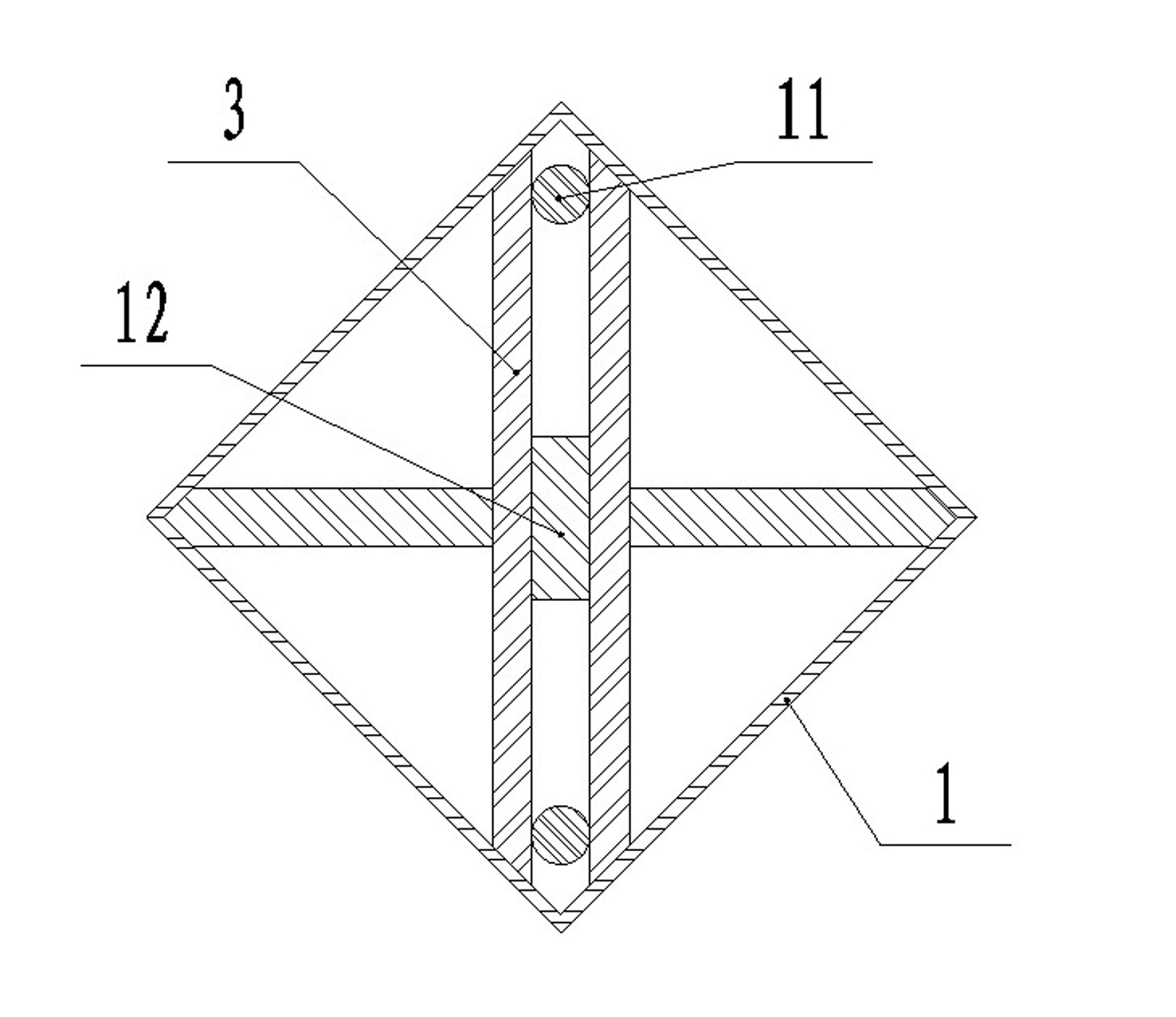

[0034] The double anti-buckling steel support with continuous constraints on the yielding thin-walled surface, including the core axial force steel part and the outer restraint steel sleeve 1, the core axial force steel part includes the yield section 2 located in the middle, and the axial force fixed on the yield section 2 The transition section 3 at both ends and the connecting section 4 fixed on the outside of the two transition sections 3, the yield section 2 is a thin-walled steel strip plate with a rectangular cross section, and each of the two connecting sections 4 includes two adjacent plates with a gap The joint steel plates parallel to each other and the joint steel plates are fixed with stiffening steel plates 5 perpendicular to their axial directions, the cross-sectional areas of the transition section 3 and the connecting section 4 are larger than the cross-sectional area of the yield section 2; the outer restraint steel sleeve 1 Covered on the yield section 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com