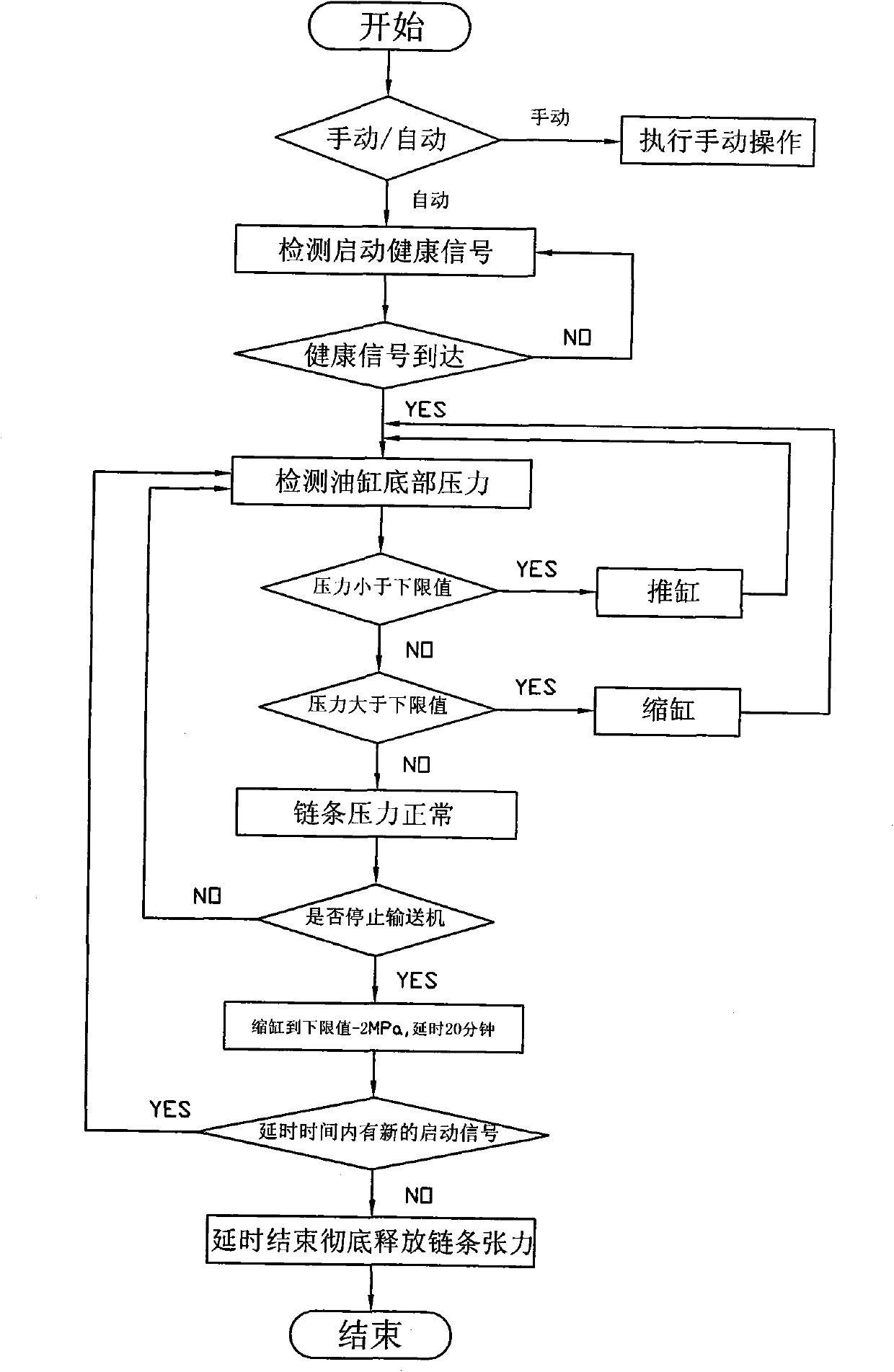

Control device for automatic tension degree of chain

A control device and automatic technology, applied in the direction of conveyor control device, transportation and packaging, conveyor, etc., can solve the problems of reduced chain life, increased chain wear, cumbersome process, etc., to increase service life, reduce manual operation, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

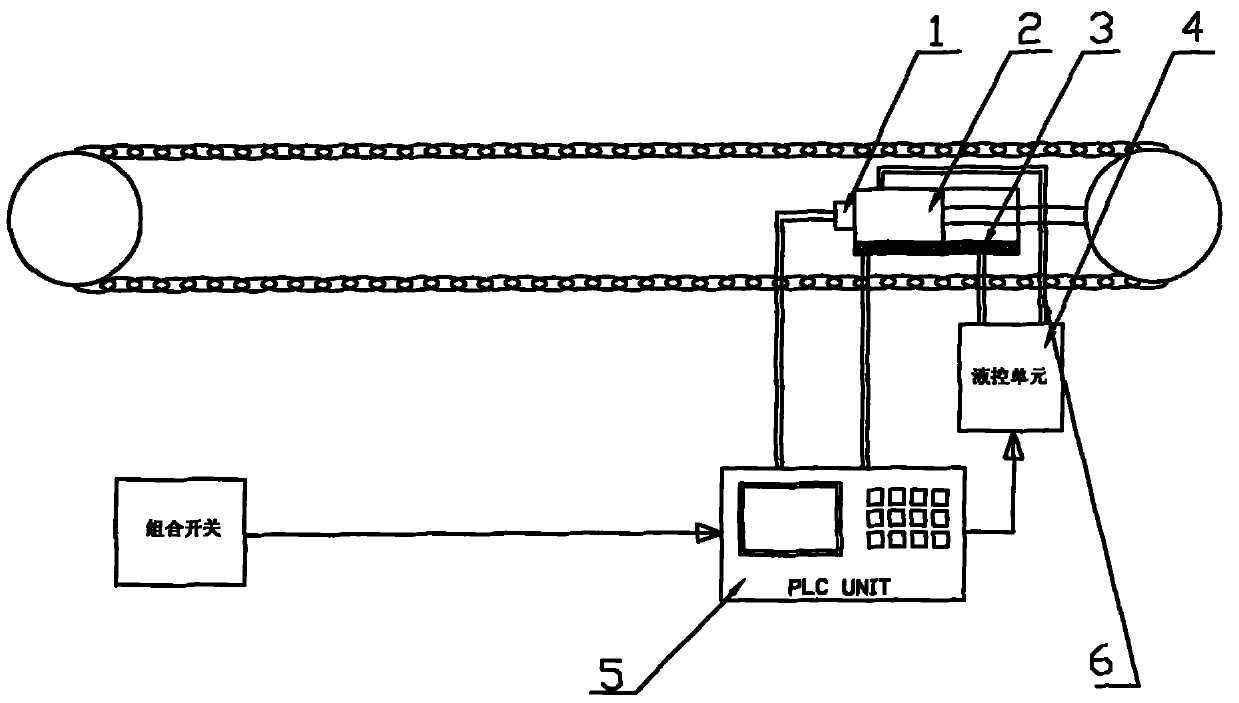

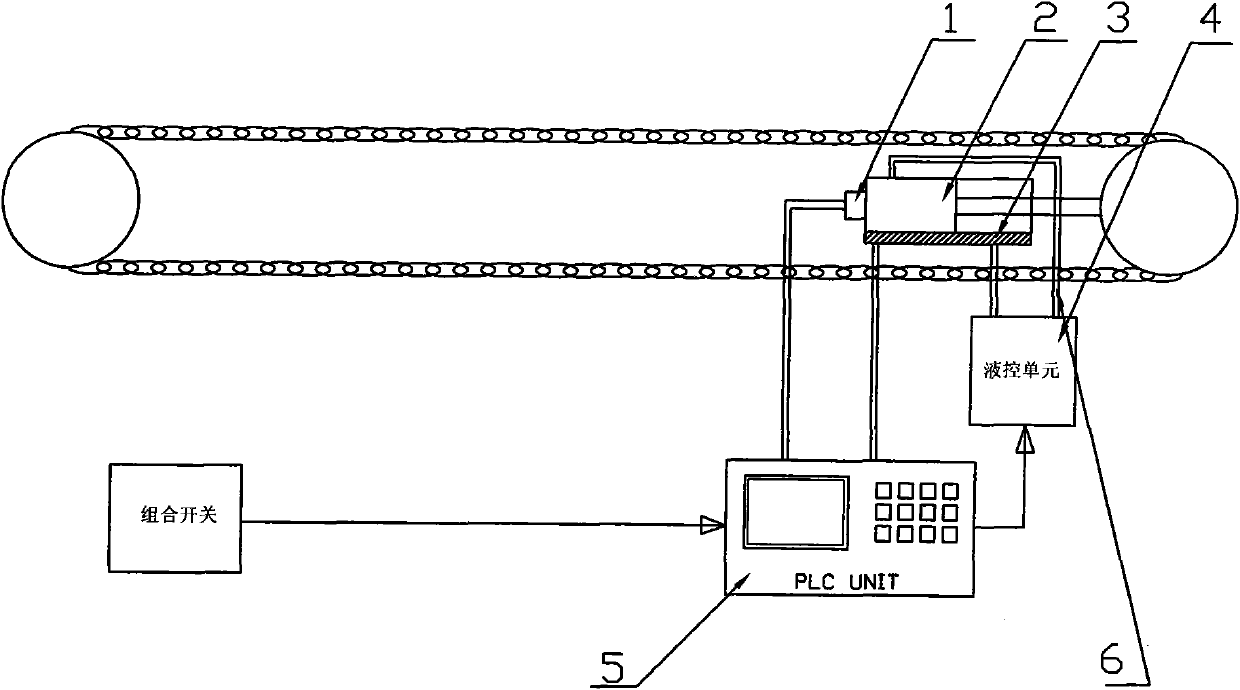

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing:

[0013] Such as figure 1 As shown, the present invention includes a pushing cylinder 2, the piston rod of the pushing cylinder 2 is connected with the shaft of the sprocket so as to push the sprocket to move linearly, the pushing cylinder 2 is also connected with the hydraulic control unit 4 through a hydraulic pipeline 6, the hydraulic pressure The control unit 4 is connected with a controller 5, and the controller 5 specifically adopts PLC, and a pressure sensor 1 and a displacement sensor 3 are respectively installed beside the push cylinder 2 so as to detect the pressure and pressure of the push cylinder 2 when the push cylinder 2 pushes the sprocket. The displacement of the pressure sensor 1 and the displacement sensor 3 are respectively connected with the aforementioned controller 5.

[0014] In addition, it also includes a combination switch, which is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com