Tyre gripping device of hydraulic tyre forming vulcanizer

A technology for shaping vulcanization and tires, which is applied in the field of automation, and can solve problems such as uneven force, the influence of tire grippers, and inaccurate positioning, and achieve the effects of ensuring vulcanization quality, repeatability accuracy, and small mechanical impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

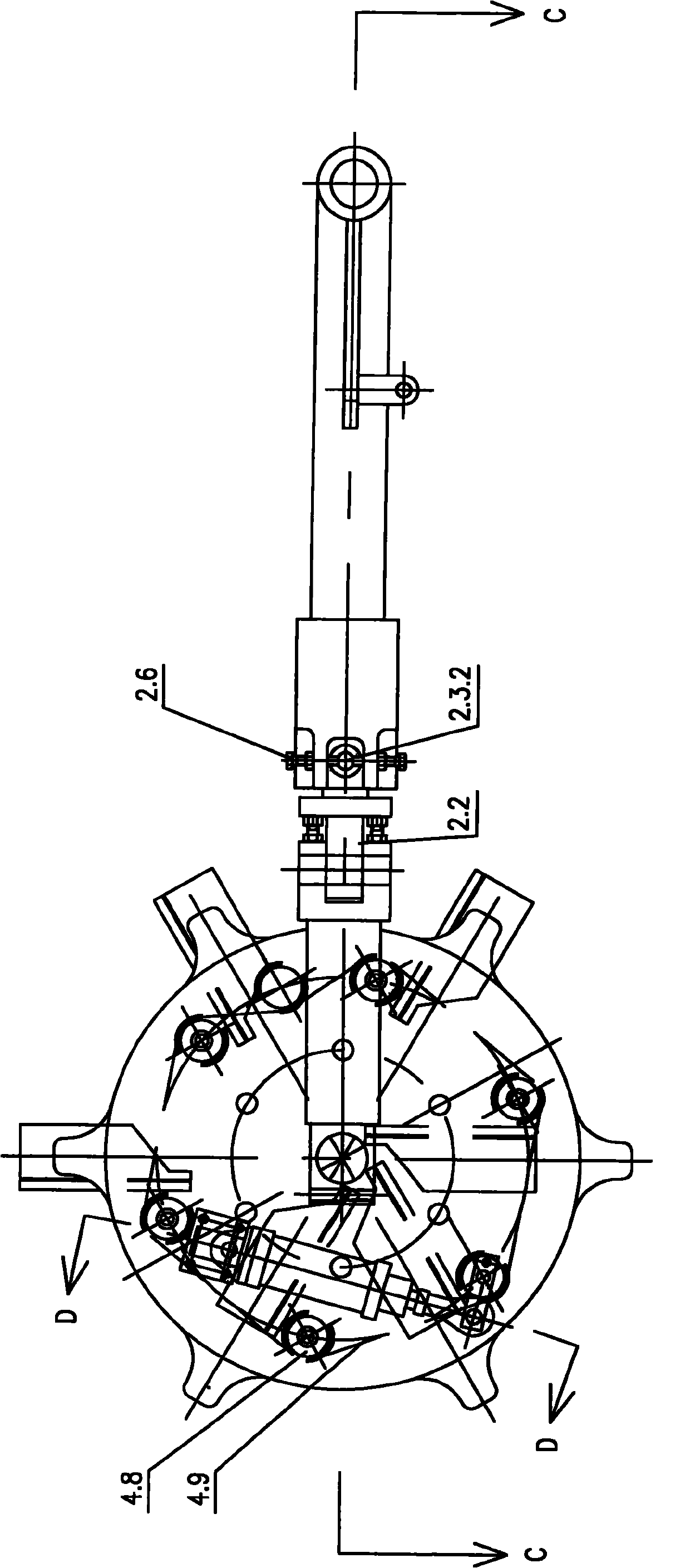

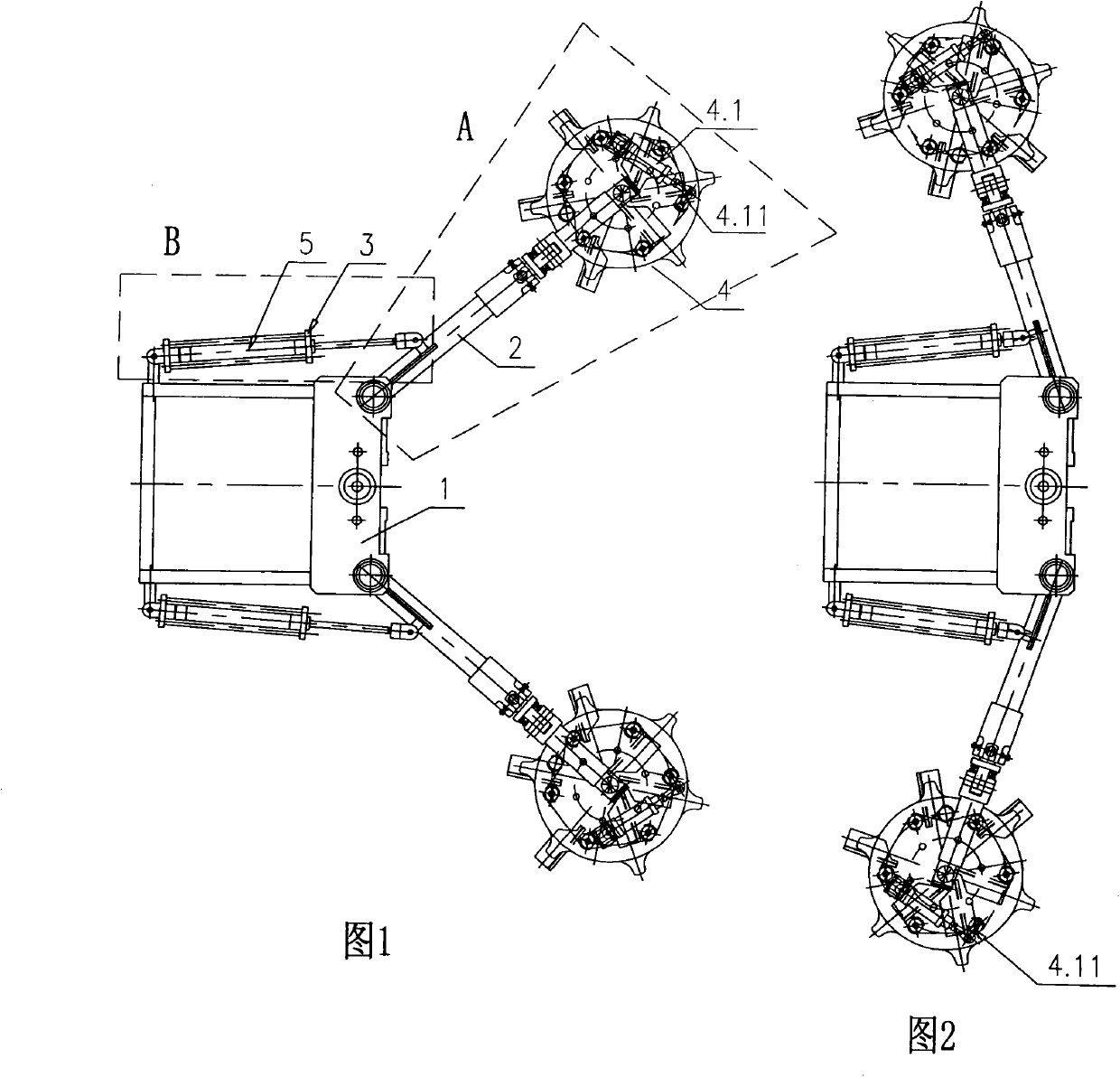

[0039] see figure 1 , figure 2 , a tire gripping device for a hydraulic tire shaping vulcanizer related to the present invention, mainly consists of a lifting frame 1, a rotating arm 2, a cylinder support 3, a tire gripping device 4, and a rotating in and out cylinder 5;

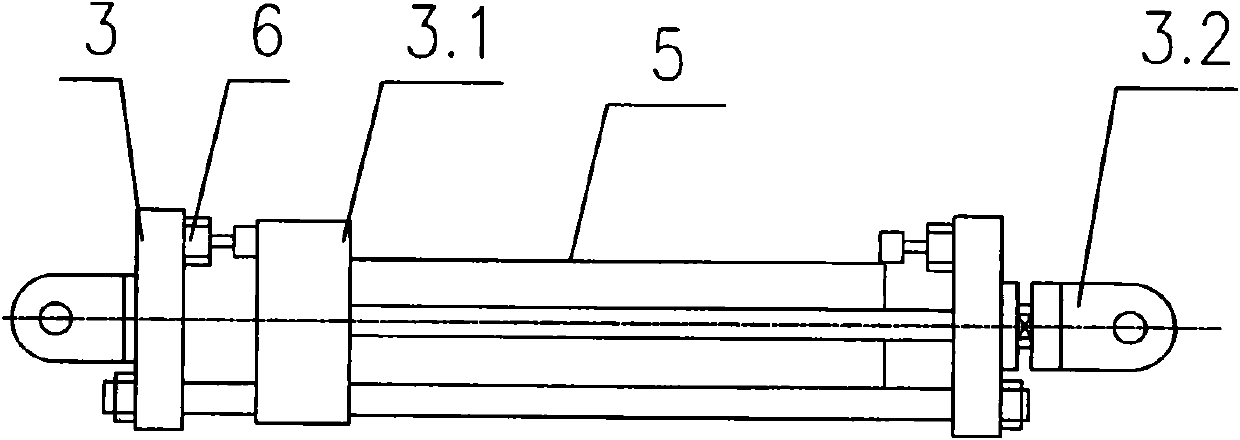

[0040] The lifting frame 1 is installed on the column of the machine platform, the rotating arm 2 is symmetrically installed on the lifting frame 1, the tire catcher 4 is installed on the rotating arm 2 through the guide shaft 4.13, and the rotating in and out cylinder 5 Installed on the cylinder bracket 3, one end of the cylinder bracket 3 is installed on the lifting frame 1, and the piston rod of the said turning in and out cylinder 5 passes through the other end of the cylinder bracket 3 and connects with the piston rod connecting seat 3.2. The pivoting arm 2 is connected.

[0041] see Image 6 , Figure 7 , the two ends of the cylinder bracket 3 are respectively equipped with a hydraulic buffer 6, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com