Low temperature resistant sweet potato storage cellar and application

A technology of low temperature resistance and sweet potato, which is applied in the field of agricultural product storage in food engineering. It can solve the problems of low cost performance in greenhouse cellars, unsuitability for popularization and application, and moisture damage in cellars. It can achieve temperature and humidity control to facilitate thermal insulation performance and overcome poor thermal insulation performance. , good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

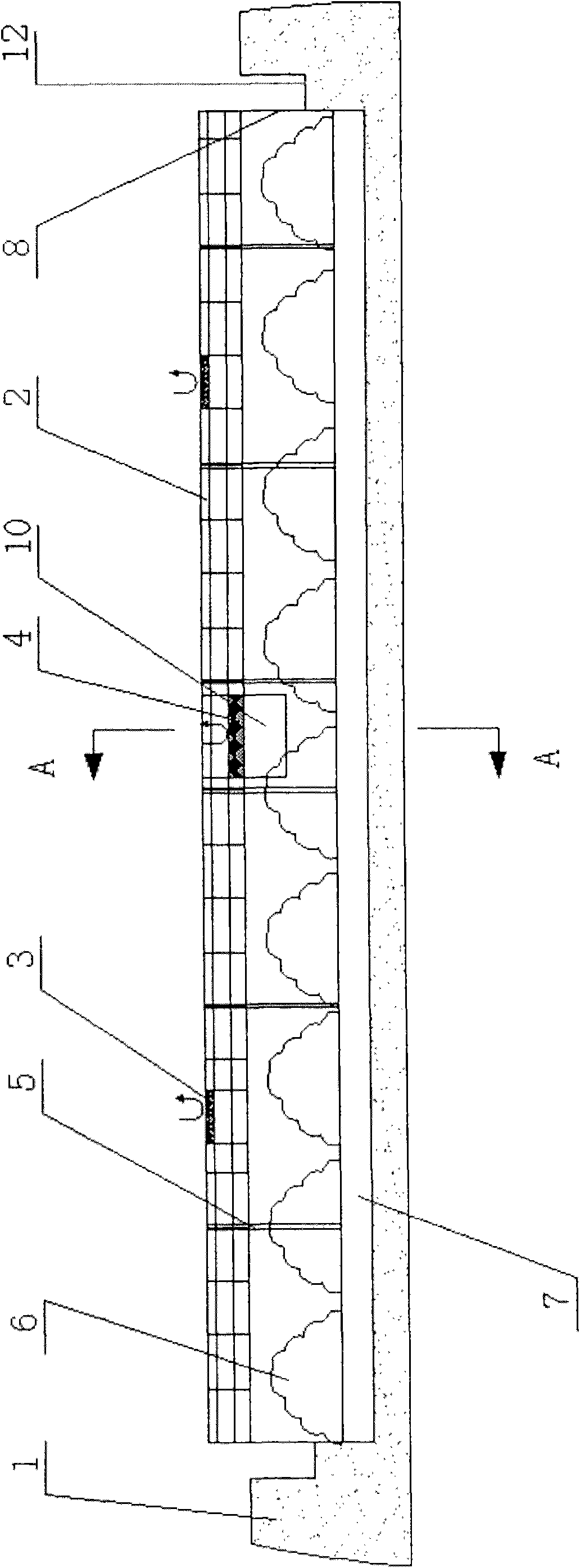

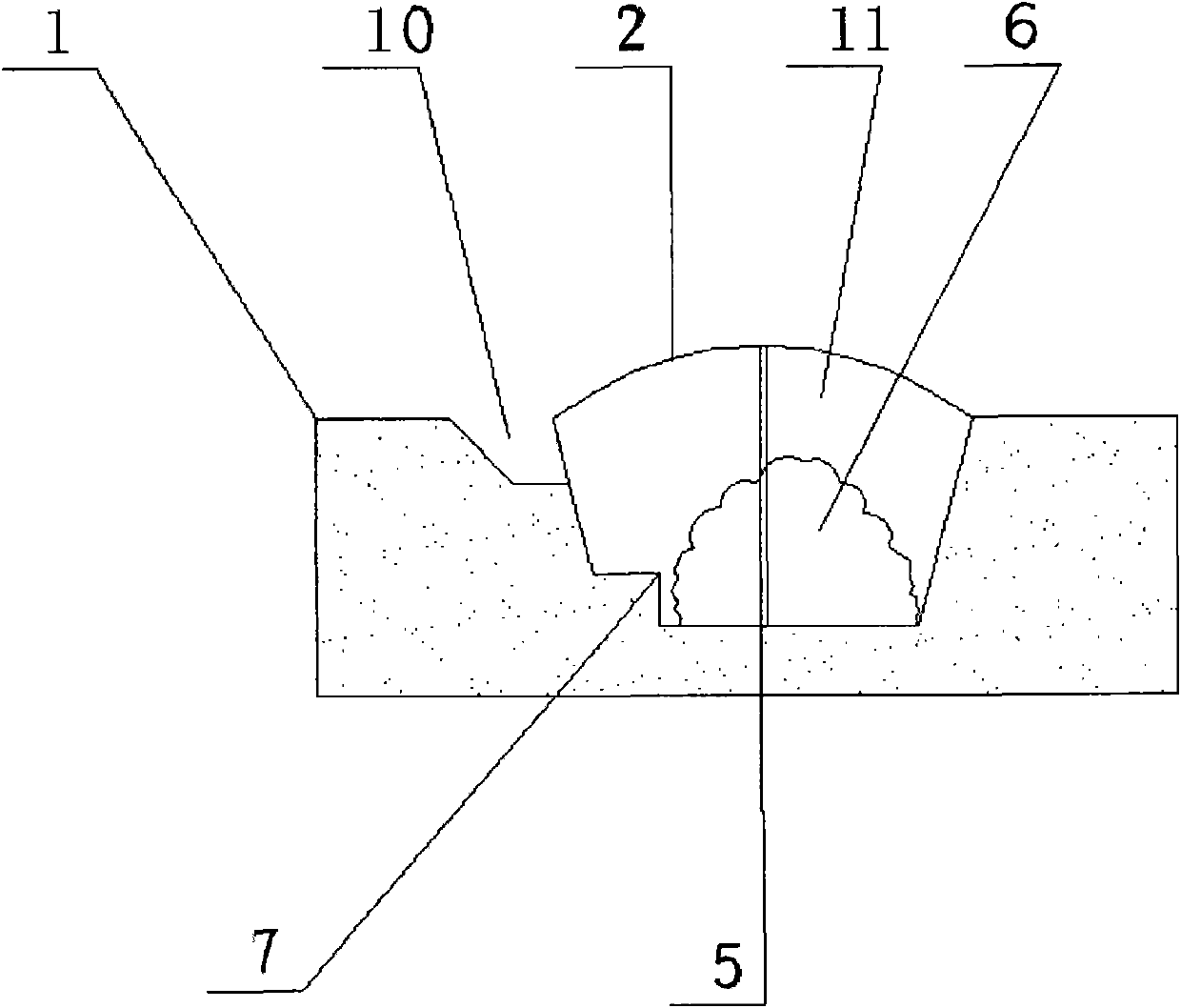

[0045] Low temperature resistant sweet potato storage cellar, the structure is as follows Figure 1-3 As shown, it includes a cellar 11 and a shed 2. The cellar 11 is located underground, and the shed 2 is located on the ground. The cellar is an inverted trapezoidal soil ditch, wide at the top and narrow at the bottom. There are air vents and delivery ports on the side of the shed. The length of the cellar is 50m, the width of the top of the cellar is 4m, the width of the bottom of the cellar is 2.6m, and the depth of the cellar is 2m. The height of the top of the arch shed 2 from the ground is 70cm. The details are as follows:

[0046] 1) Choose a flat and well-drained plot around, and dig a 50m-long inverted trapezoidal ditch underground as the cellar 11. The earth walls on both sides of the ditch are inclined, which is conducive to load bearing, and the ditch is deep (that is, the cellar is deep). 2m, the width of the top of the ditch (that is, the width of the top of th...

Embodiment 2

[0048] Embodiment 2, the application of cold-resistant sweet potato storage cellar

[0049] Utilize the method for storing sweet potatoes in the low-temperature-resistant sweet potato storage cellar described in embodiment 1, the steps are as follows:

[0050] Sweet potato variety for storage: Jishu No. 18 sweet potato; storage time: mid-October to early April of the following year.

[0051] 1) Clean the cellar, use sulfur fumigation and disinfection, put in 10 grams of sulfur per square meter, and sterilize in a multi-point combustion manner. After 22 hours of airtight fumigation and disinfection, ventilate for 24 hours to complete the disinfection of the storage cellar;

[0052] 2) Harvest the sweet potatoes in good time. When the sweet potatoes are harvested, the temperature is higher than 10°C. On the day of harvest, the sweet potatoes need to be dried in the sun for 3-4 hours, and then select good quality potato pieces without injury or disease and pack them into the cell...

Embodiment 3

[0056] Low-temperature-resistant sweet potato storage cellar, as shown in the structure example 1, the difference is: the length of the cellar 11 is 100m, the width of the top of the cellar is 4.1m, the width of the bottom of the cellar is 2.8m, and the depth of the cellar is 2.2m. The height of the arc shed 2 from the ground is 75cm. The details are as follows:

[0057] 1) adopt the same method as embodiment 1 to dig a long 100m inverted trapezoidal ditch underground as the cellar chamber 11, the earth walls on both sides in the ditch are inclined, which is conducive to load bearing, and the ditch depth (i.e. cellar chamber depth) is 2.2m, The top width of the ditch (that is, the top width of the cellar) is 4.1m, and the width of the bottom of the ditch (that is, the bottom width of the cellar) is 2.8m; a delivery step 7 with a height of 50cm and a width of 50cm is set on the side of the bottom of the cellar where there is a delivery port. The length of cargo step 7 is ident...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com