LED (Light Emitting Diode) condensing lens

A concentrating lens and lens technology, applied in the field of lighting, can solve problems such as uneven spot, and achieve the effect of small beam divergence angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

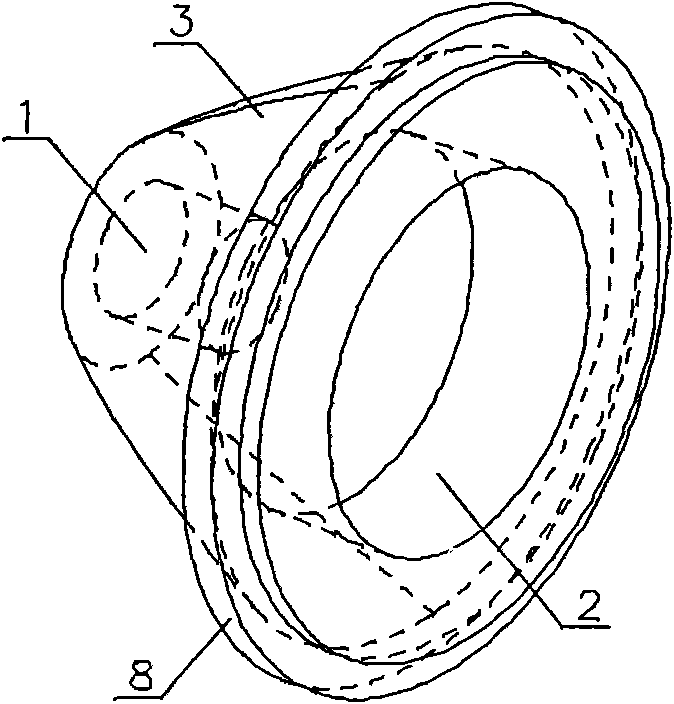

[0026] Such as figure 1 , 2 Shown is an LED condenser lens, the lens is a truncated cone lens made of optical material with a refractive index of 1.4-1.7. The optical material specifically selected is PMMA or PC material, and the refractive index of PMMA material is 1.494, and the refractive index of PC material is 1.591, and the rear end face of frustum-shaped lens has cylindrical first refraction groove 1, and lens front face has cylindrical first refraction groove 1. The second refraction groove 2, the outer wall 3 of the lens is a total reflection surface, and the groove walls of the first refraction groove 1 and the second refraction groove 2 form a refraction surface. Wherein the refraction surface of the first refraction groove 1 is its surrounding side wall 5 and bottom surface 6 respectively, the refraction surface of the second refraction groove 2 is its bottom surface 7, and the first refraction groove 1 and the second refraction groove 2 are symmetrical about the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com