Method and device for controlling electrolysis current density

A control device and electrolytic current technology, applied in the field of power supply, can solve the problems of presetting by production workers, difficulty in controlling current density, inability to accurately, quantify, and intuitively display and control the current density value, affecting the quality and stability of processed products, etc. , to achieve the effect of accurate quality control, ensure product quality and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

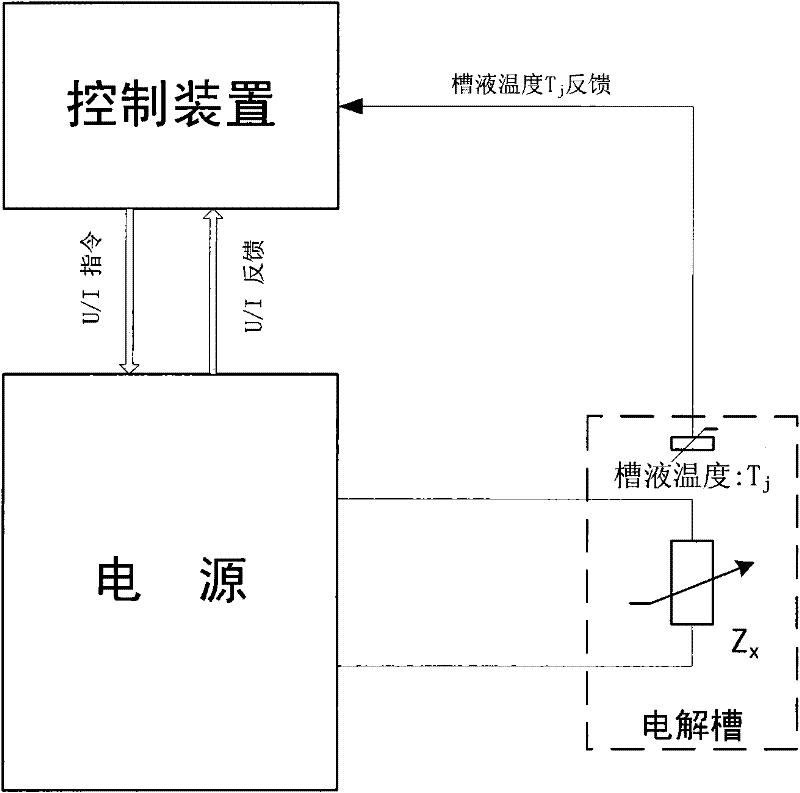

[0030] see figure 1 , the present invention is illustrated by anodizing as an example:

[0031] In the anodizing treatment circuit composed of current density control power supply, bath liquid, parts (or test board), line copper bar, anode part hanger and cathode lead plate, etc., the loop load is mainly caused by the surface of the part (or test board) The equivalent resistance of the corresponding bath solution, the equivalent capacitance of the oxide film formed on the surface of the part, and the leakage resistance of the oxide film;

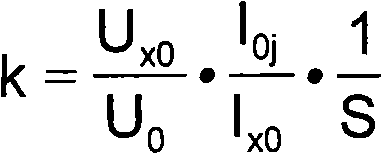

[0032] For anodic oxidation, at the initial stage of energized oxidation treatment, the oxide film on the surface of the part (or test plate) has not yet formed, and the load characteristic of the entire circuit is purely resistive, that is, the load is the corresponding bath liquid on the surface of the part (or test plate) Equivalent resistance R x , the equivalent capacitance C of the oxide film at this time m =0, the leakage resistanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com