Composite bonding agent for sliding plate refractory material and preparation method thereof

A composite binder and refractory technology, which is applied in the directions of aldehyde/ketone condensation polymer binders, binder types, binder additives, etc., can solve problems such as unfavorable industrial production, limited dispersibility improvement, and complex processes. Achieve the effects of being beneficial to industrial production, improving oxidation resistance and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

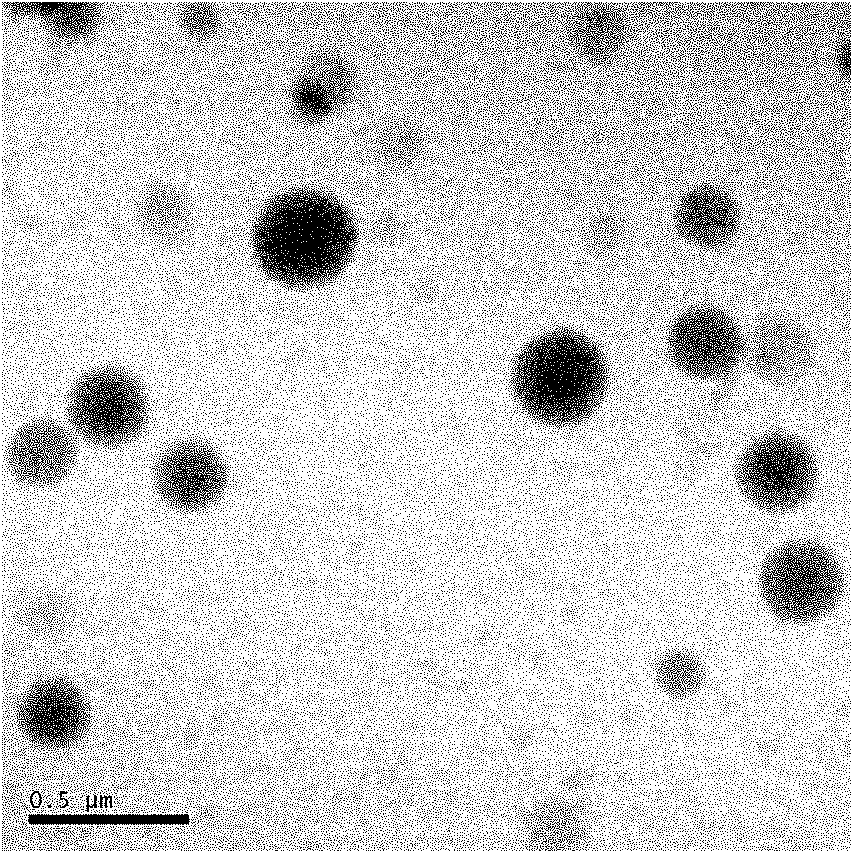

[0013] A composite binder for a sliding board refractory material and a preparation method thereof. Add absolute ethanol to the phenolic resin to configure a 30-40wt% phenolic resin absolute ethanol solution; then add the modified white carbon black to the phenolic resin absolute ethanol solution, and the modified white carbon black The addition amount is 1-5wt% of the phenolic resin, stirred at 30-40°C for 3-4 hours to obtain a white carbon black modified phenolic resin mixed solution; then the white carbon black modified phenolic resin mixed solution is decompressed Ethanol is distilled off to obtain a composite binder for sliding board refractory materials.

[0014] The preparation method of the modified white carbon black in this embodiment is: the white carbon black is the white carbon black produced by the vapor phase method, the particle size of the white carbon black is 7-40nm, and the specific surface area is 150-400m 2 / g. First activate the white carbon black at 2...

Embodiment 2

[0018] A composite binder for a sliding board refractory material and a preparation method thereof. Except that the modifier is Tween 60, the preparation method of the composite binder for the slide plate refractory is the same as in Example 1.

[0019] The properties of the slide plate refractory material prepared with the composite binder obtained in this example are: the flexural compressive strength is 100-145MPa, and the bulk density is 3.13-3.14g / cm 3 , The weight gain rate after hydration is 0.21-0.29%, and the strength retention rate after hydration is 90.65-93.43%.

Embodiment 3

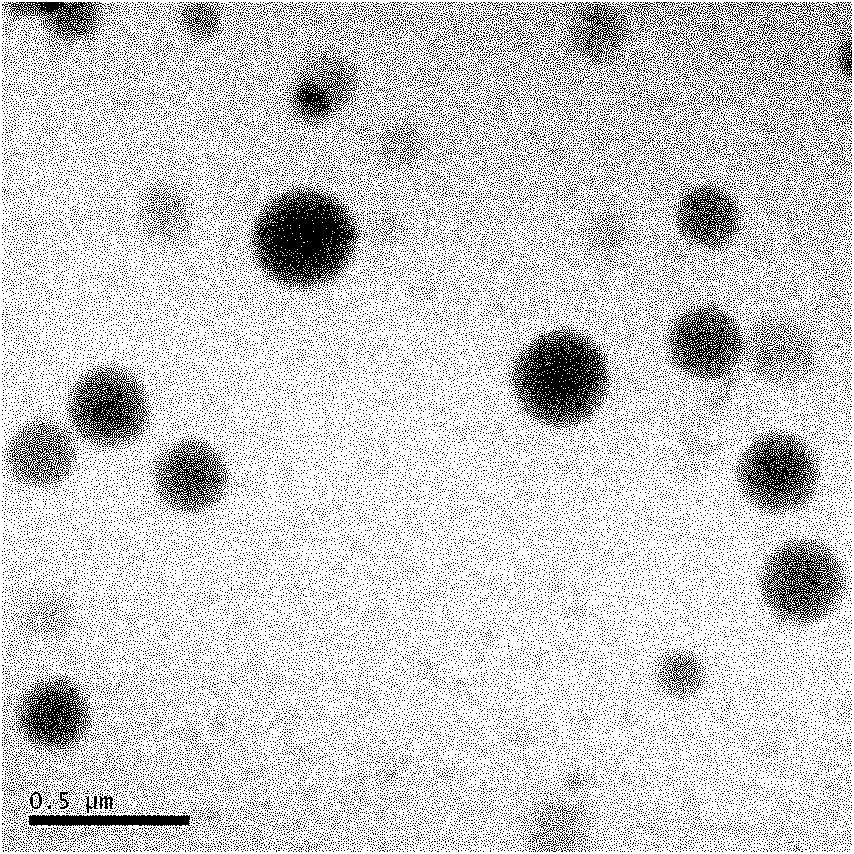

[0021] A composite binder for a sliding board refractory material and a preparation method thereof. Add absolute ethanol to the phenolic resin to configure a 40-50 wt% phenolic resin absolute ethanol solution; then add the modified white carbon black to the phenolic resin absolute ethanol solution, and the modified white carbon black The addition amount is 5-10wt% of the phenolic resin, stirred at 40-50°C for 4-5 hours to obtain a white carbon black modified phenolic resin mixed solution; then the white carbon black modified phenolic resin mixed solution is decompressed Ethanol is distilled off to obtain a composite binder for sliding board refractory materials.

[0022] The preparation method of the modified white carbon black in this embodiment is: the white carbon black is the white carbon black produced by the vapor phase method, the particle size of the white carbon black is 7-40nm, and the specific surface area is 150-400m 2 / g. First activate the white carbon black at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| Strength retention | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com