Cracking auxiliary agent-containing paste composition

A composition and size technology, which is applied in the field of size composition to improve the desizing efficiency of glass fibers, can solve the problems of affecting the strength of glass fibers, consuming energy, etc., to reduce the desizing time, reduce the desizing temperature, and improve the desizing efficiency. The effect of slurry efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

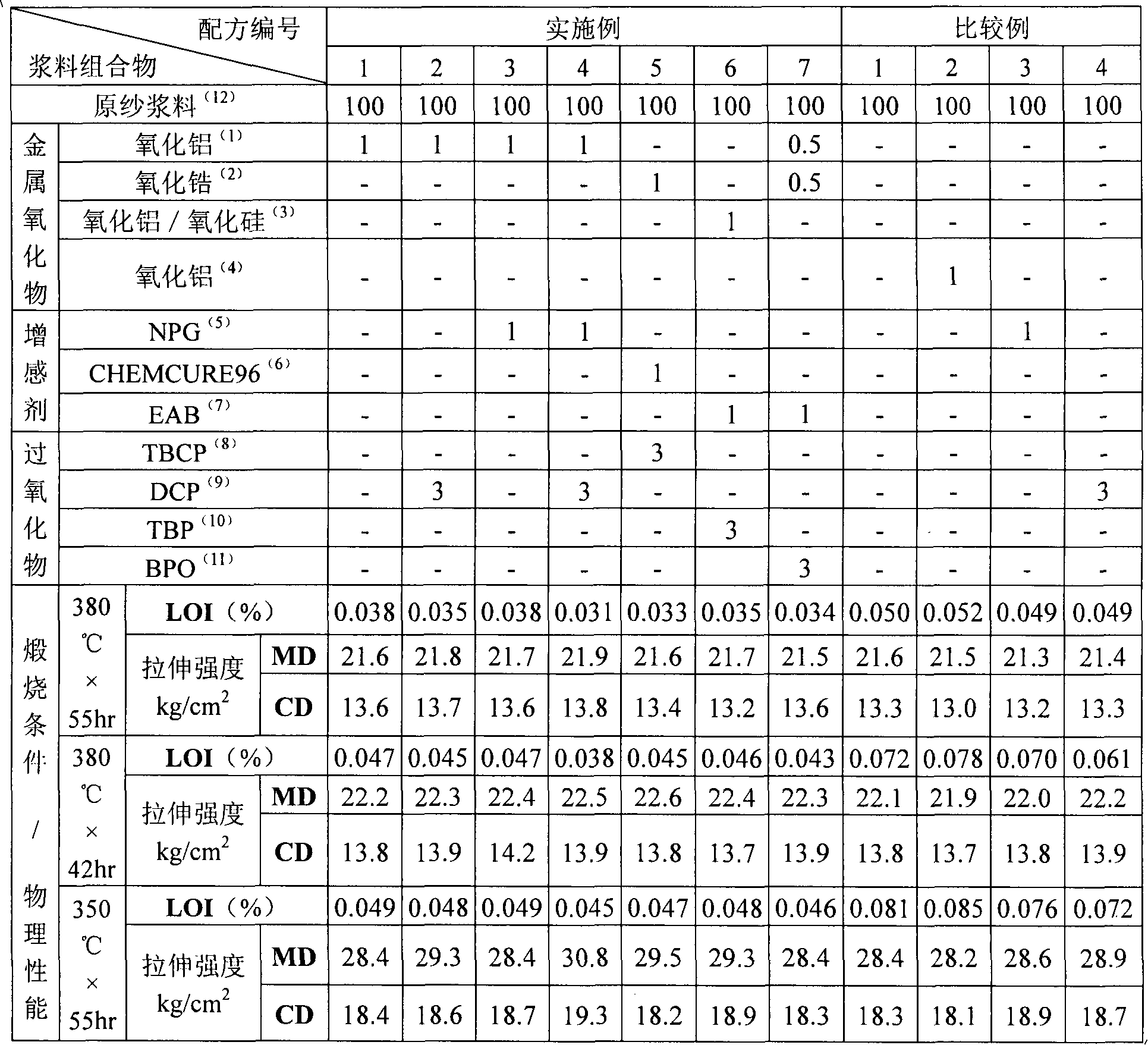

[0057] Take 100 grams of the current raw yarn size according to Table 1, add 1 gram of alumina with a particle size of 10 nm and evenly mix it into a slurry. The desizing loss on ignition (LOI%) and longitudinal and transverse (MD, CD) tensile strength of the glass fiber cloth were evaluated according to the above test methods.

[0058] The test results are shown in Table 1. Calcined at 380°C for 55 hours, the loss on ignition rate was 0.038%, and the MD / CD tensile strength was 21.6 / 13.6kg / cm 2 ; Calcined at 380°C for 42 hours, the loss on ignition rate is 0.047%, and the MD / CD tensile strength is 22.2 / 13.8kg / cm 2 ; Calcined at 350°C for 55 hours, the loss on ignition rate is 0.049%, and the MD / CD tensile strength is 28.4 / 18.4kg / cm 2 .

[0059] The loss on ignition rate of the slurry is all below 0.05%, and the tensile strength after calcination at 350°C for 55 hours is the highest, indicating that the lower the calcination temperature, the higher the tensile strength.

Embodiment 2

[0061] According to Table 1, take 100 grams of the current raw yarn size, add 1 gram of alumina with a particle size of 10 nm and 3 grams of peroxide DCP and evenly mix to form a slurry.

[0062] The test results are shown in Table 1. Calcined at 380°C for 55 hours, the loss on ignition rate of the slurry is 0.035%, and the MD / CD tensile strength is 21.8 / 13.7kg / cm 2 ; Calcined at 380°C for 42 hours, the loss on ignition rate of the slurry is 0.045%, and the MD / CD tensile strength is 22.3 / 13.9kg / cm 2 ; Calcined at 350°C for 55 hours, the loss on ignition rate of the slurry is 0.048%, and the MD / CD tensile strength is 29.3 / 18.6kg / cm 2 .

[0063] The loss on ignition rate of the slurry is all below 0.05%, and the tensile strength after calcination at 350°C for 55 hours is the highest, indicating that the lower the calcination temperature, the higher the tensile strength.

Embodiment 3

[0065] According to Table 1, take 100 grams of the current raw yarn size, add 1 gram of alumina with a particle size of 10 nm and 1 gram of sensitizer NPG and mix evenly to form a slurry.

[0066] The test results are shown in Table 1. Calcined at 380°C for 55 hours, the loss on ignition of the slurry was 0.038%, and the MD / CD tensile strength was 21.7 / 13.6kg / cm 2 ; Calcined at 380°C for 42 hours, the loss on ignition rate of the slurry is 0.047%, and the MD / CD tensile strength is 22.4 / 14.2kg / cm 2 ; Calcined at 350°C for 55 hours, the loss on ignition rate of the slurry is 0.049%, and the MD / CD tensile strength is 28.4 / 18.7kg / cm 2 .

[0067] The loss on ignition rate of the slurry is all below 0.05%, and the tensile strength after calcination at 350°C for 55 hours is the highest, indicating that the lower the calcination temperature, the higher the tensile strength.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com