Tensioning winch transmission device of belt conveyer

A technology for belt conveyors and transmissions, applied in transmissions, gear transmissions, conveyors, etc., can solve the problems of low efficiency of hydraulic motors, slow response of hydraulic systems, high prices, etc., to reduce installation space, extend The service life and the effect of preventing safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

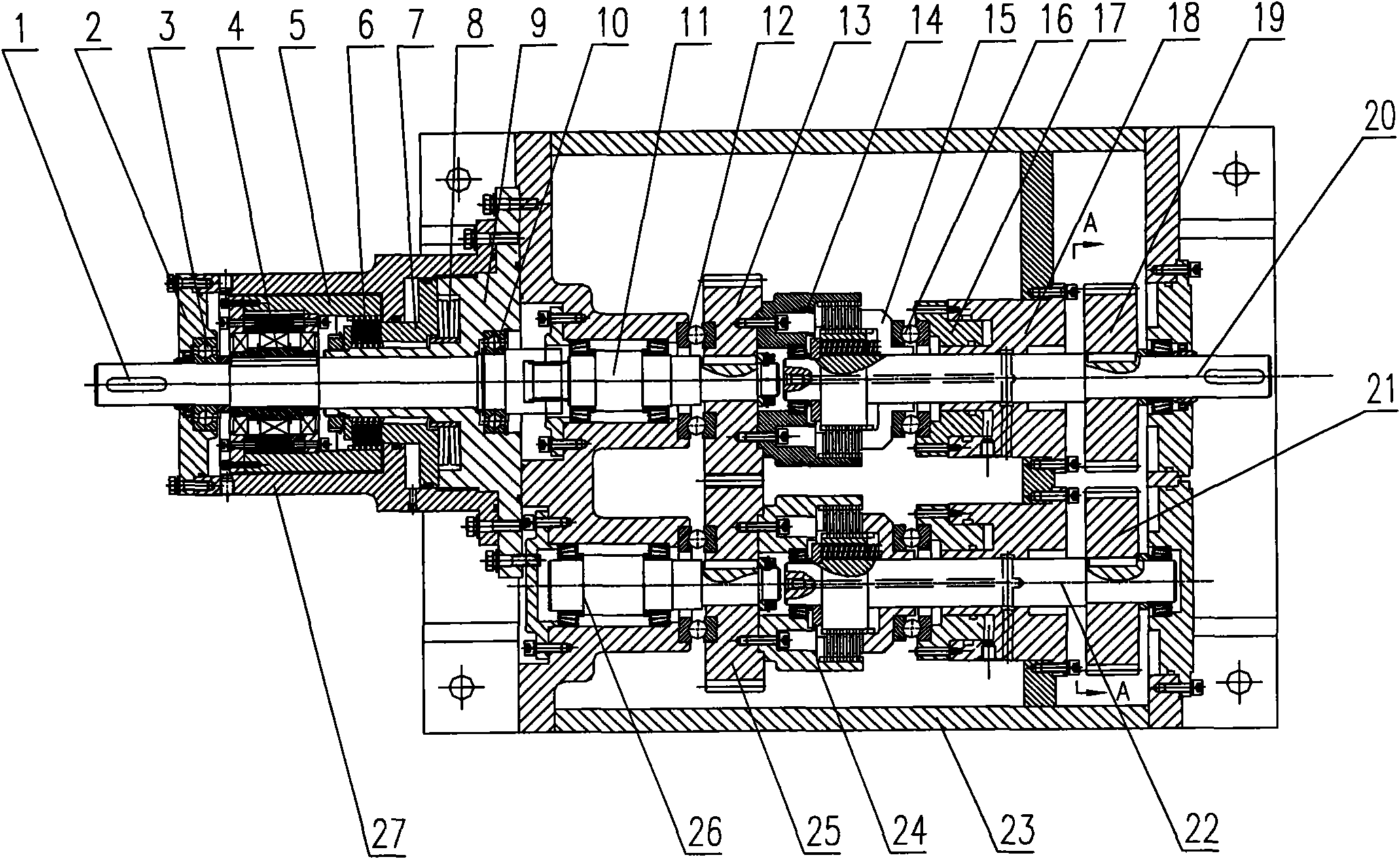

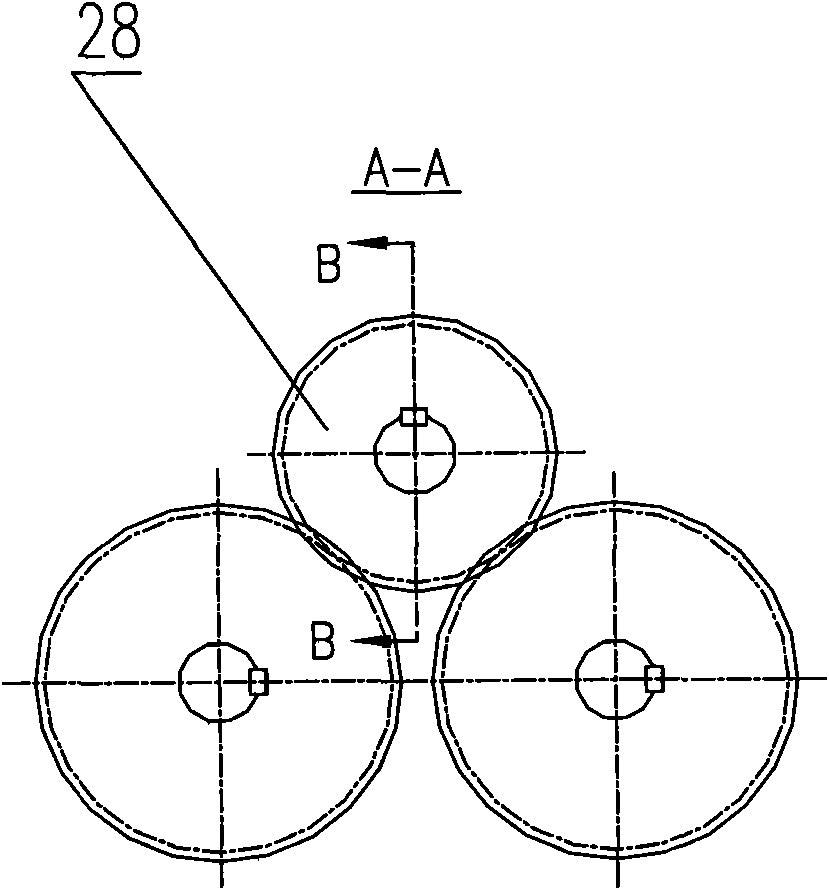

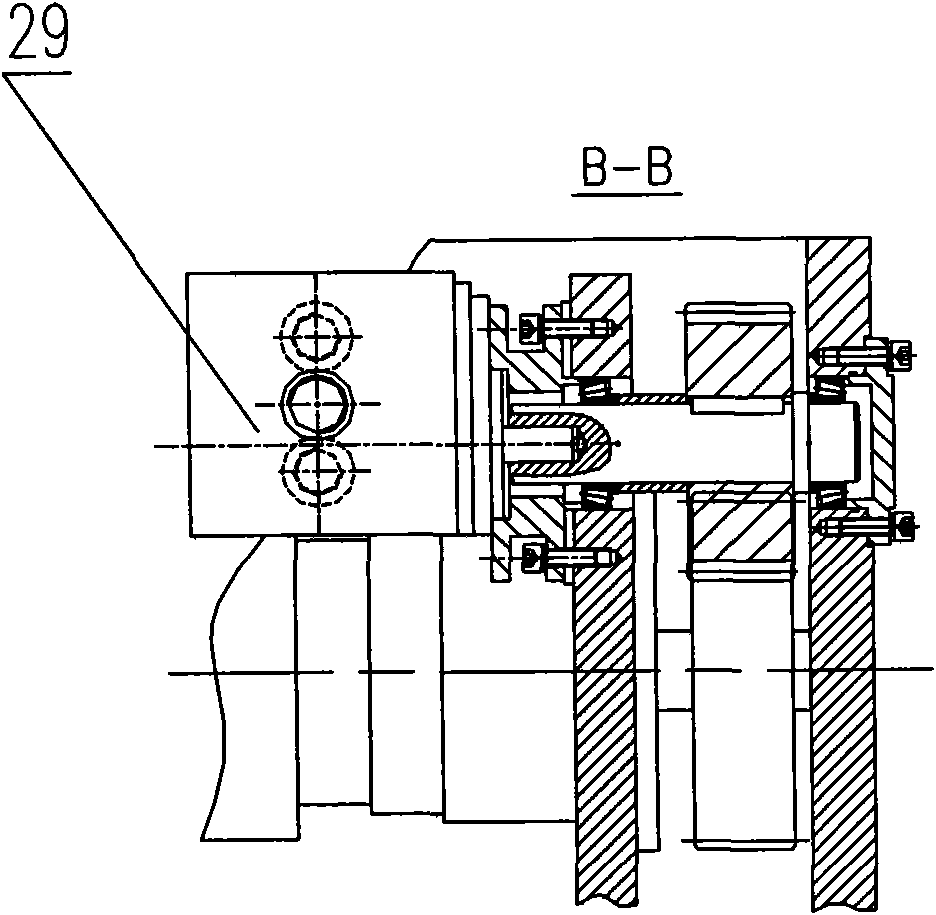

[0016] figure 1As shown, the belt conveyor tensioning winch transmission device is mainly composed of a casing 26, a main transmission mechanism arranged in parallel in the casing 26, an auxiliary transmission mechanism and an output transmission mechanism connected to the main transmission mechanism. The main transmission mechanism is mainly composed of input shaft 22, main clutch output shaft 11, main clutch fixed gear 14, main clutch 15, main clutch thrust plate 16, main clutch oil cylinder piston 18, main clutch oil cylinder 19, main input shaft gear 20; The transmission mechanism is mainly composed of auxiliary clutch input shaft gear 23, auxiliary clutch input shaft 25, auxiliary clutch oil cylinder piston 27, auxiliary clutch thrust plate 29, auxiliary clutch 30, auxiliary clutch fixed gear 31, auxiliary clutch output shaft 34; auxiliary clutch thrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com