Surface texture method of solar battery silicon slice

A technology of surface texture and solar cells, which is applied in the field of solar cells, can solve the problems of reduced reflectivity, inability to use alkali texture technology, and irregular orientation, etc., and achieve low average reflectivity, strong repeatability and technology transplantation , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

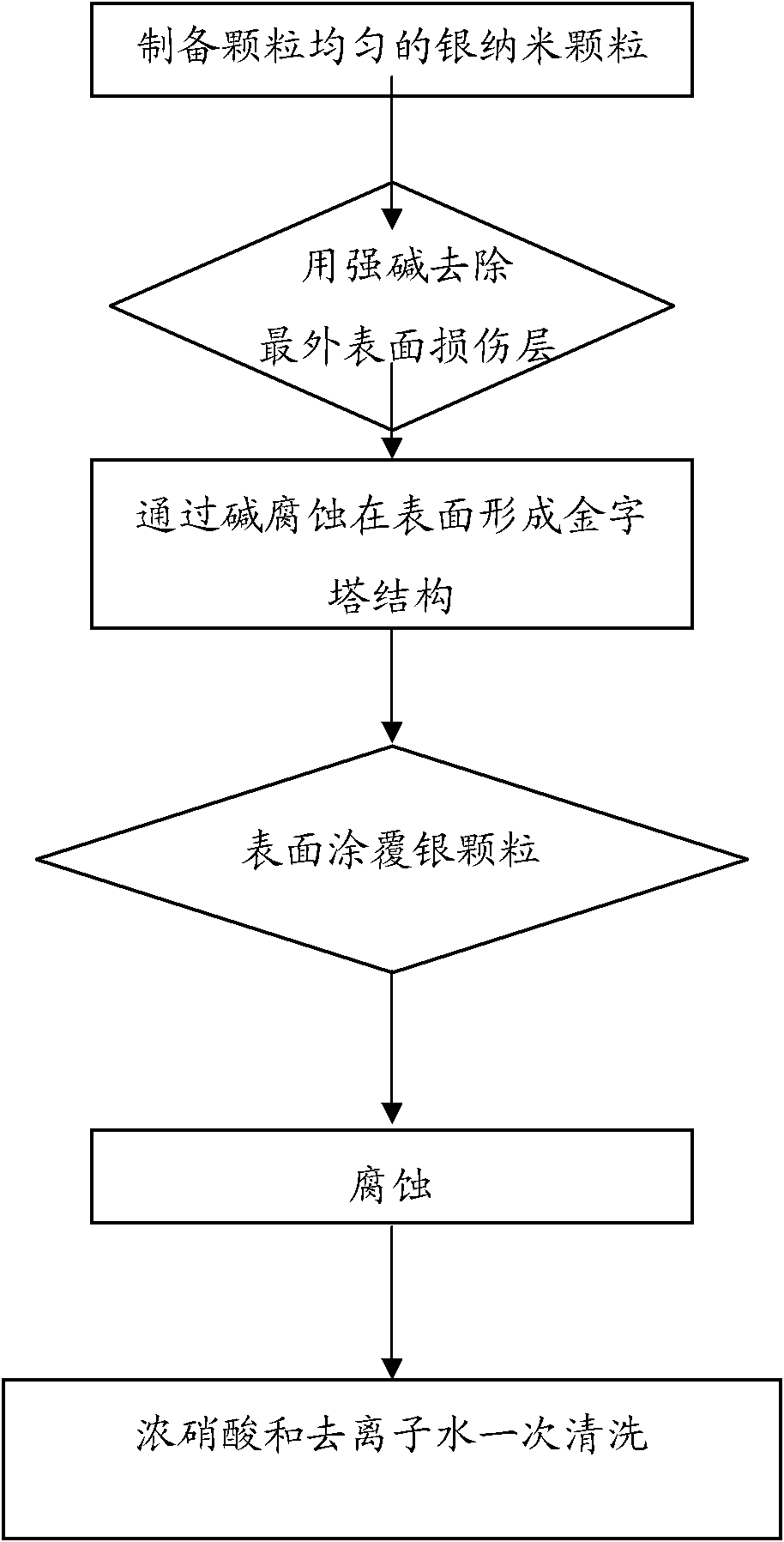

[0041] see figure 1 , the process of using nanoscale silver particles to texture a single crystal silicon wafer is as follows:

[0042] (1) Utilize chemical method to prepare nanoscale silver particle, preparation process is: react with silver nitrate and ethylene glycol, PVP is as additive, silver nitrate and ethylene glycol mass ratio are 1: 179, the mass ratio of PVP and silver nitrate is 4.2:1, the reaction temperature is 100°C; the prepared nano-scale silver particles are well dispersed, with an average size of 18-25nm, and its TEM is as follows: Figure 6 shown;

[0043] (2) Using potassium hydroxide solution to remove the damaged layer on the silicon wafer, wherein the mass percentage concentration of potassium hydroxide is 10.5%, the corrosion time is 10min, and the corrosion temperature is 80°C;

[0044] (3) Using potassium hydroxide solution to pre-texture the silicon wafer to obtain a pyramid shape, wherein the mass percentage concentration of potassium hydroxide ...

Embodiment 2

[0049] see figure 1 , the process of using nanoscale silver particles to texture a single crystal silicon wafer is as follows:

[0050] (1) Utilize the chemical method to prepare the nanoscale silver particle that average size is 18~25nm, preparation process is: react with silver nitrate and ethylene glycol, without additive, silver nitrate and ethylene glycol mass ratio are 1: 194, reaction temperature is 120°C;

[0051] (2) Use potassium hydroxide solution to remove the damaged layer on the silicon wafer, wherein the concentration of potassium hydroxide is 15% by mass, the corrosion time is 8min, and the corrosion temperature is 85°C;

[0052] (3) Use potassium hydroxide solution to pre-texture the silicon wafer to obtain a pyramid shape, wherein the concentration of potassium hydroxide is 3% by mass, the corrosion time is 65min, and the corrosion temperature is 90°C;

[0053] (4) uniformly coat the silver particles on the product of (3), with a thickness of 0.5mm, and dry...

Embodiment 3

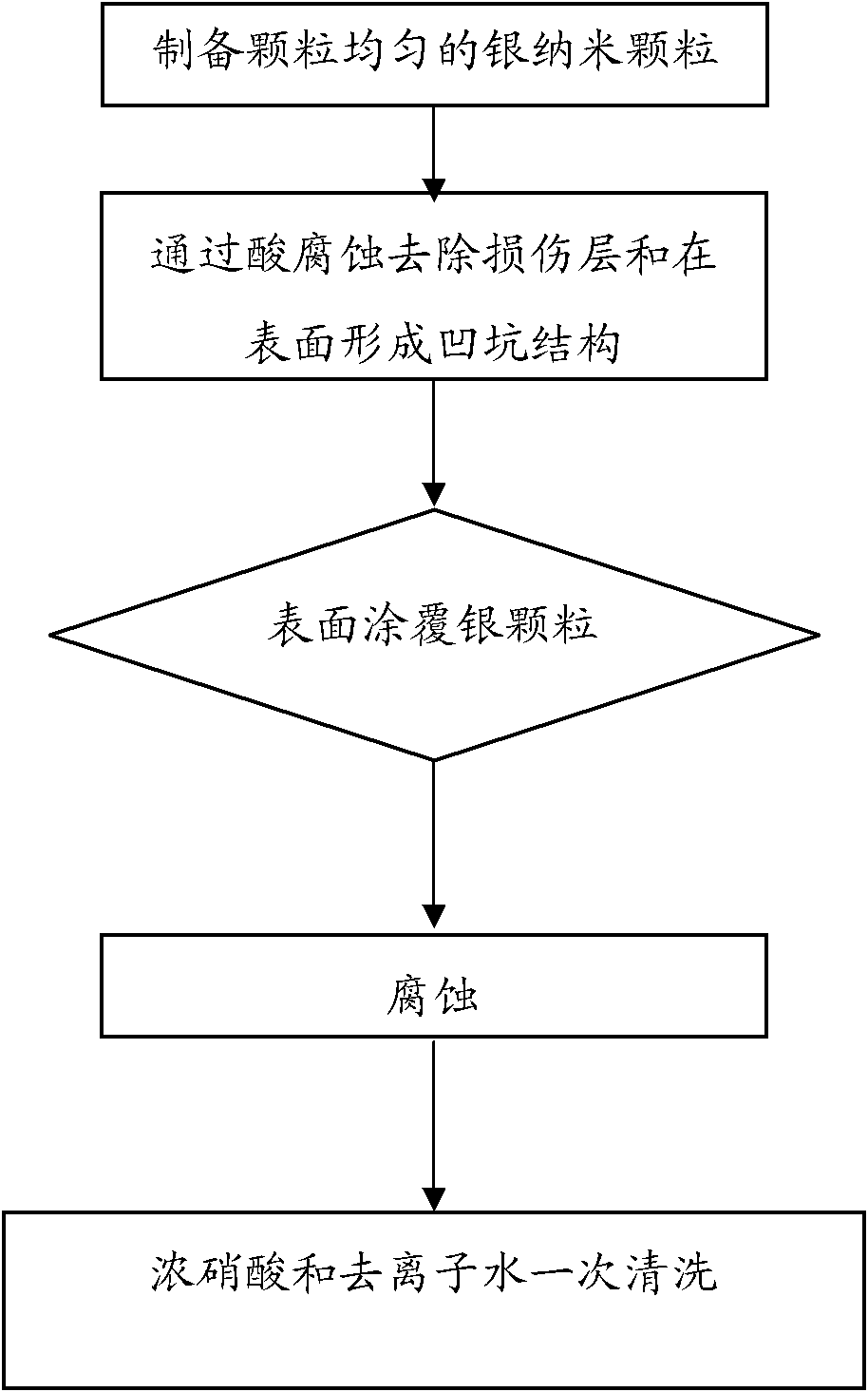

[0058] see figure 2 , the process of using nano-scale silver particles to texture polycrystalline silicon wafers is as follows:

[0059] (1) Utilize the chemical method to prepare nanoscale silver particles with an average size of 8-11nm, the preparation process is: react with silver nitrate and ethylene glycol, PEI is used as an additive, the mass ratio of silver nitrate and ethylene glycol is 1: 152, PEI The mass ratio with silver nitrate is 5:1, and the reaction temperature is 115°C;

[0060] (2) Use an acid mixed solution to remove the damaged layer and pre-texture the silicon wafer, wherein the acid mixed solution is an aqueous solution of nitric acid and hydrofluoric acid, wherein the nitric acid with a mass percentage concentration of 60% and the hydrofluoric acid with a mass percentage concentration of 40% The volume ratio of the solution is 14:1, the volume ratio of the hydrofluoric acid solution with a mass percent concentration of 40% to deionized water is 1:5, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com