Exposure method of exposure machine

An exposure method and technology of an exposure machine, applied in the field of exposure, can solve the problems of waste of processing costs, a large exposure machine, and a complex structure of the exposure machine, thereby reducing the number of bulbs, improving applicability and practicability, and reducing heat accumulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

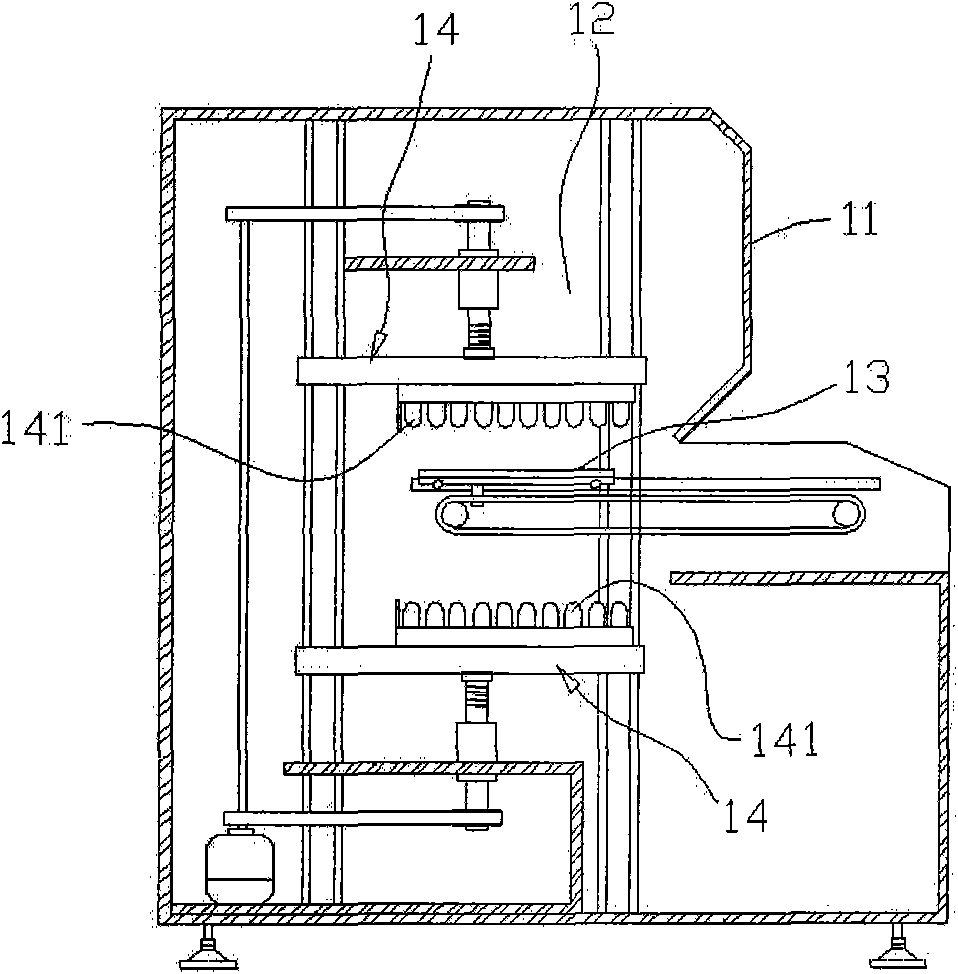

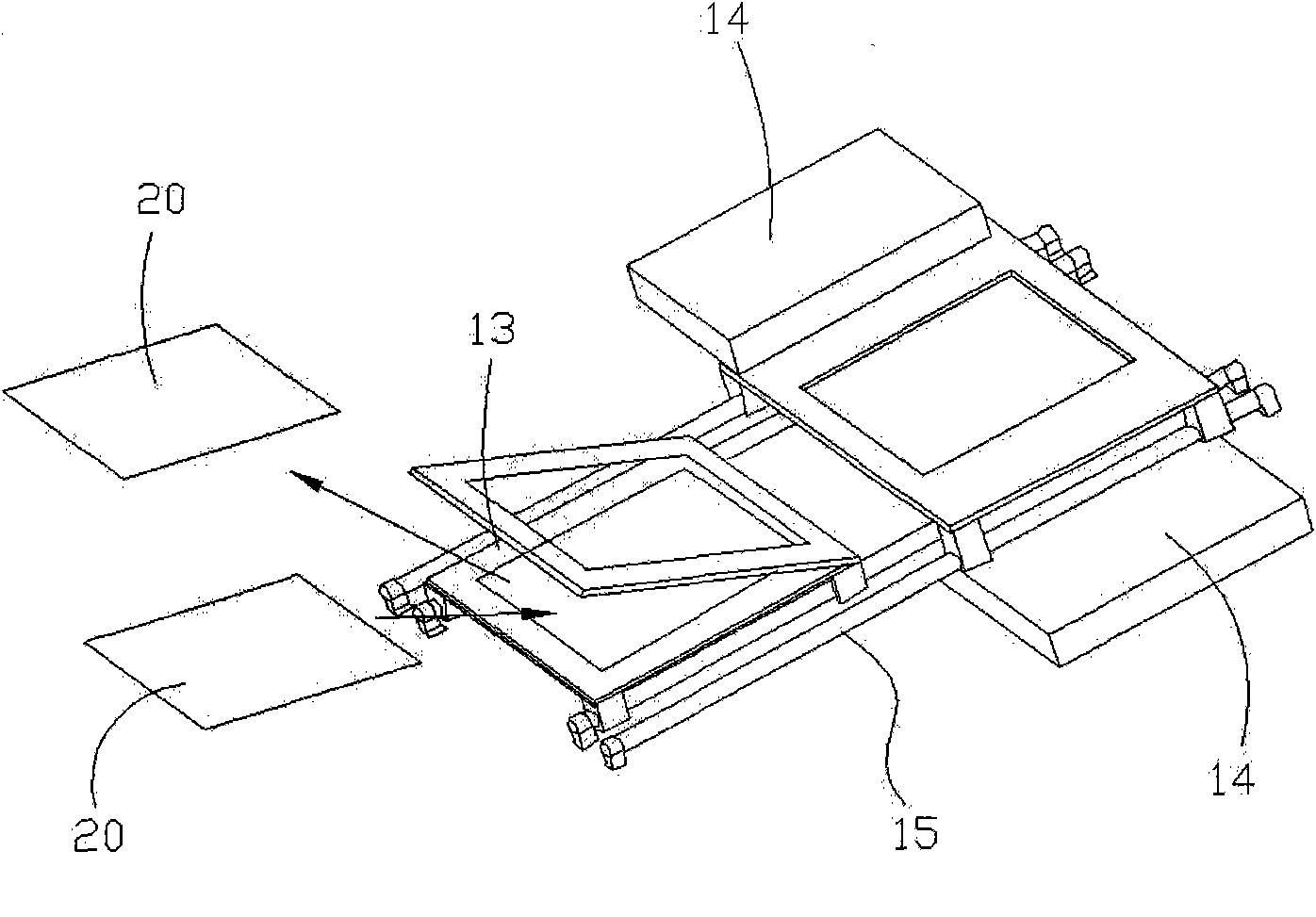

[0037] The purpose of the present invention is to provide an exposure machine that can perform exposure operations on a specific area of an exposure platform, relatively does not generate heat accumulation, and can reduce equipment volume and cost, as well as an exposure method related to it; the exposure method is first in Above an exposure platform for carrying workpieces and originals, at least one light source group is provided to generate exposure light toward the exposure platform, and then the light source group is displaced according to a preset path to allow the exposure light source to reach the exposure platform. The predetermined area of the platform is used to expose and develop the processed object on the exposure platform.

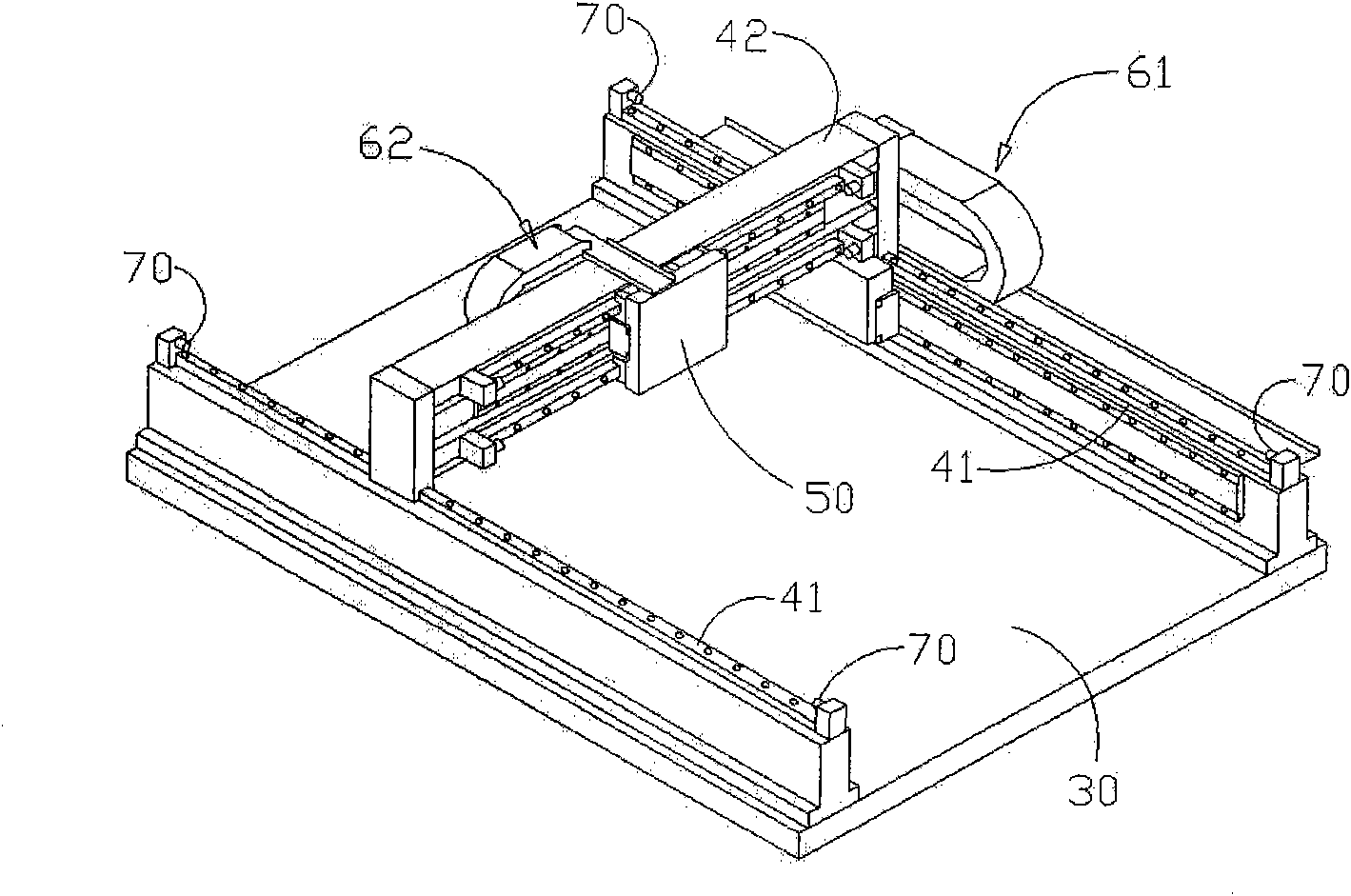

[0038] Such as image 3 and Figure 4 As shown, the exposure machine of the present invention includes: an exposure platform 30, two first linear slide rails 41, at least one second linear slide rail 42, at least one light source group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com