Adjustable water nozzle for oilfield water injection and water distributor with same

A technology for oil field water injection and water distributor, which is applied in the fields of production fluid, wellbore/well components, earth-moving drilling, etc. Good, simplified connection and meshing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

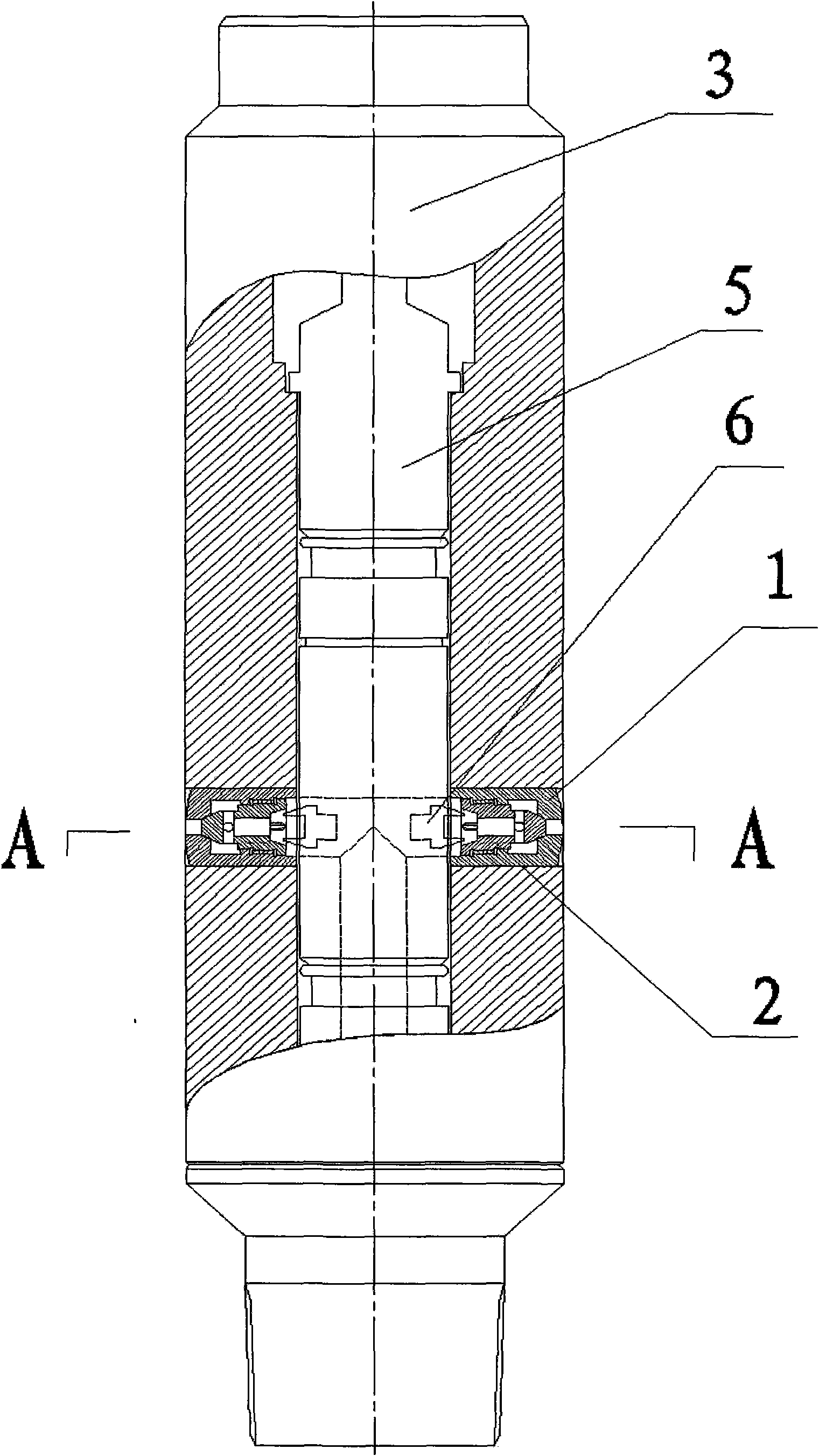

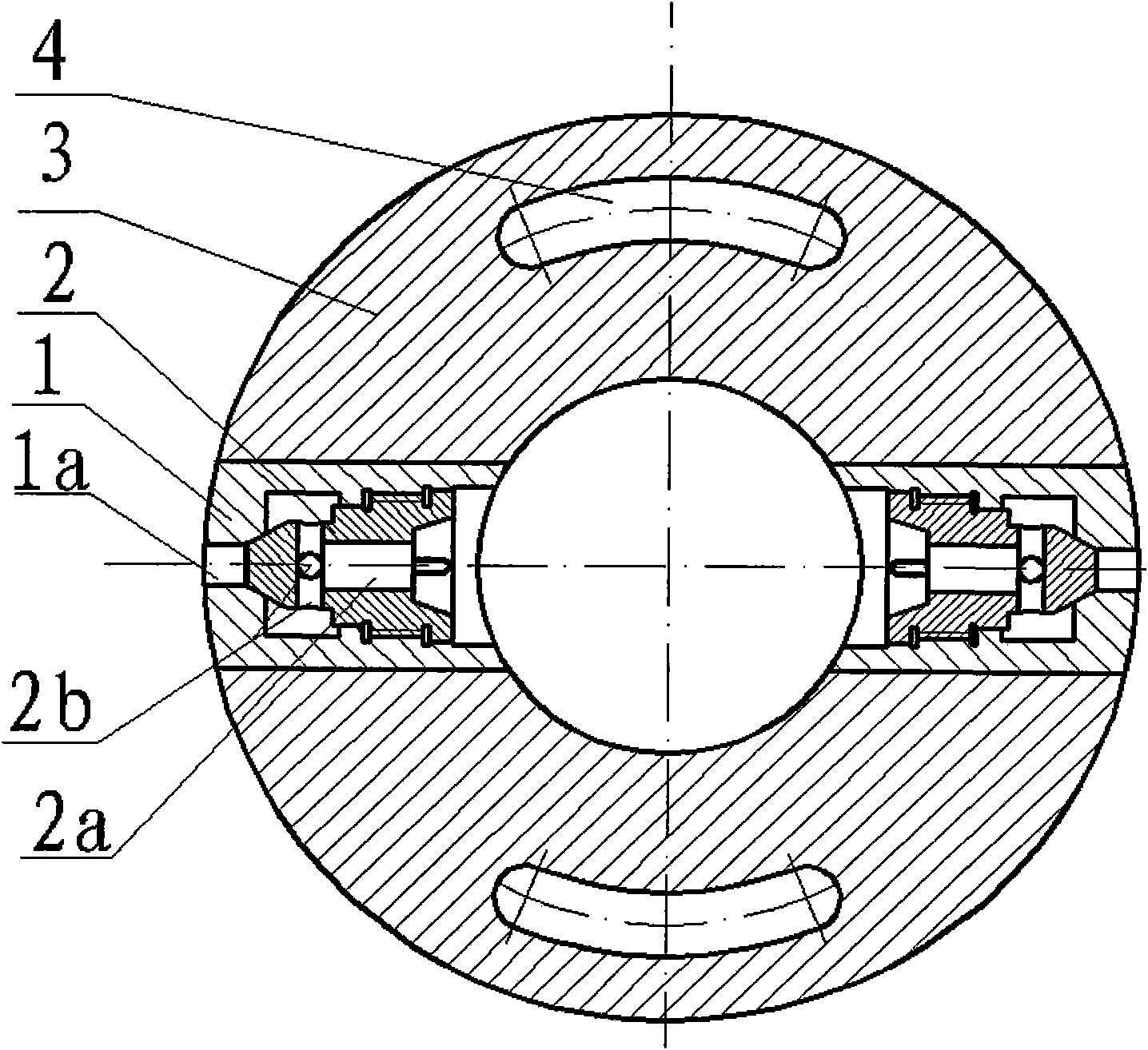

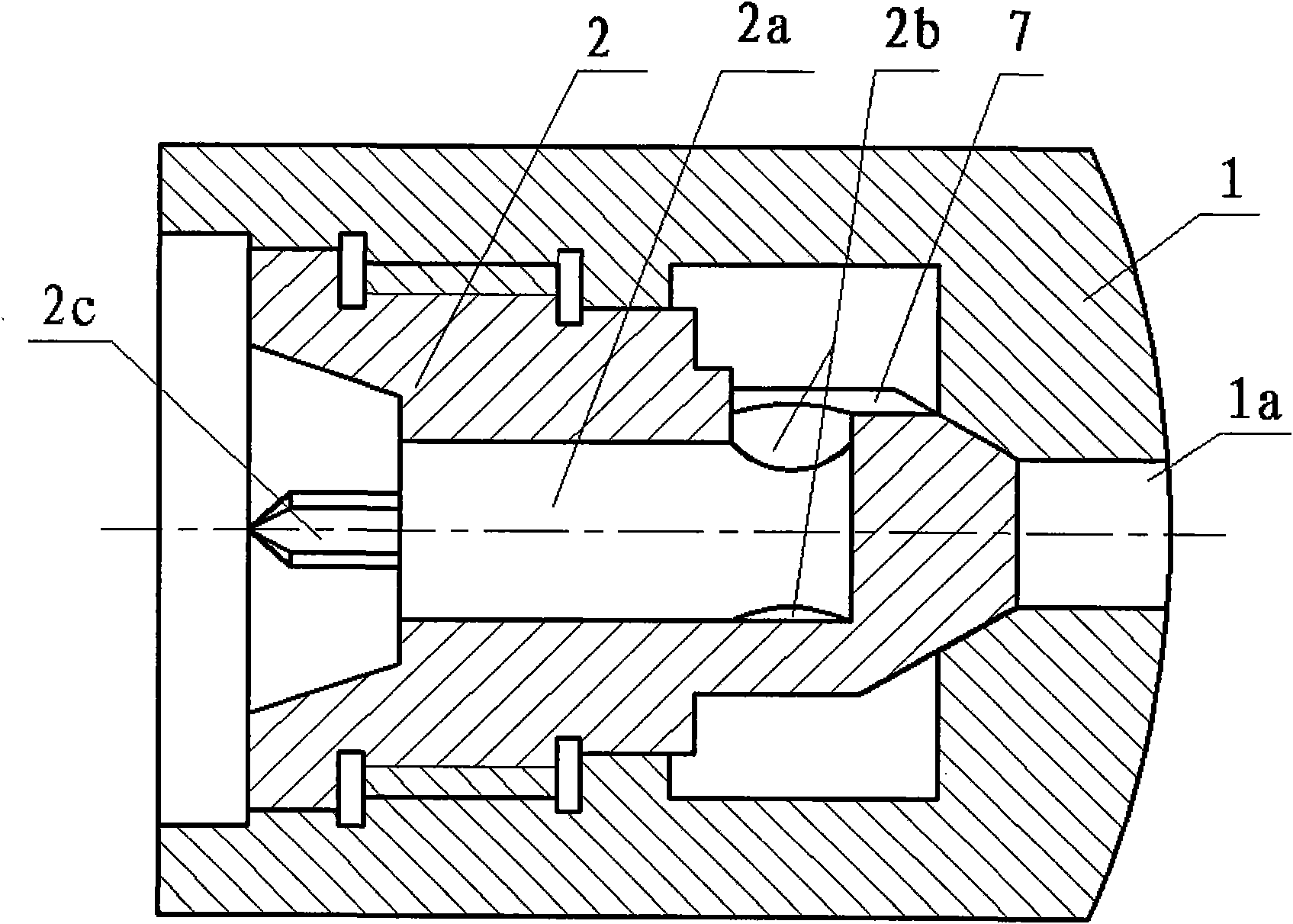

[0043] Example 1 as figure 1 , figure 2 , image 3 As shown, the adjustable nozzle for oilfield water injection of the present invention includes a valve sleeve 1 and a valve core 2 arranged in the valve sleeve 1. The valve sleeve is a cavity structure, and the outside of the valve core 2 is connected to the The inner wall is threadedly connected, the valve sleeve 1 is provided with a water outlet hole 1a, the head of the valve core 2 is in sealing fit with the taper surface of the valve sleeve 1 water outlet hole 1a, and the side of the valve core 2 head is provided with 3 A side hole 2b, a water inlet hole 2a is arranged in the valve core 2, and the water inlet hole 2a communicates with the three side holes 2b on the head of the valve core 2, and the head of the valve core 2 is provided with There is a diversion groove 7 connected to the side hole 2b, so that water injection can enter the cavity through the side hole 2b, and also easily enter the water outlet hole 1a thro...

Embodiment 2

[0044] Embodiment 2 is similar to Embodiment 1, and its difference is: described side hole 2b is 4, and 4 are evenly distributed with the head side of spool 2, and described water inlet hole 2a is 2, enters The water holes 2a are merged and distributed in the center of the valve core 2 and are separated from each other. The water inlet hole 2a communicates with all the side holes 2b. Groove 7, so that water injection can enter the cavity through side hole 2b, and also easily enter into water outlet hole 1a through diversion groove 7, playing the role of drainage. There are four claw petals 2c, and the cross section of the claw petals 2c is based on the center of the spool 2 as a sector shape with an included angle of 45°. The included angle between the end faces of the tail is 45°, the head of the valve core 2 is configured as a conical structure, and the outlet hole 1a of the valve sleeve 1 is configured as a conical structure corresponding to the conical structure of the hea...

Embodiment 3

[0045] Embodiment 3 is similar to Embodiment 1, and its difference is: described side hole 2b is 5, and 5 side holes 2b are evenly distributed on the head side of valve core 2, and described water inlet hole 2a is 3 One, the three water inlet holes 2a are combined and arranged at the center of the valve core 2, which are separated from each other, all the water inlet holes 2a communicate with all the side holes 2b, and the head of the valve core 2 is set There is a diversion groove 7 connected to the side hole 2b, so that water injection can enter the cavity through the side hole 2b, and also easily enter the water outlet hole 1a through the diversion groove 7, playing the role of drainage. There are 5 claw petals 2c, and the cross section of the claw petals 2c is based on the center of the valve core 2 as a sector shape with an included angle of 60°. The angle between the end faces of the tail is 60°, the head of the valve core 2 is configured as a conical structure, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com