Hollow fiber spinning nozzle of insertion tube type

A spinning nozzle and tube-inserting technology, which is applied to the field of inserting-tube porous spinning nozzles, can solve the problems of normal production, loss of concentricity, damage to the needle seat of the injection needle, etc., so as to facilitate disassembly and cleaning and ensure the spinning quality. , the effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

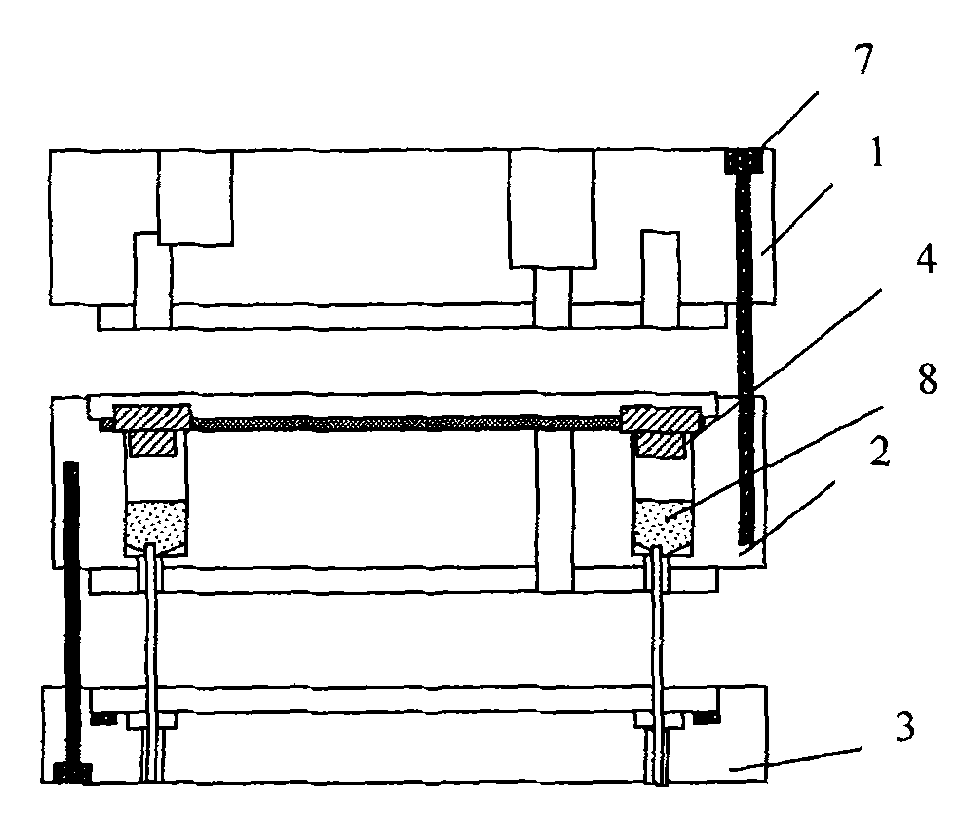

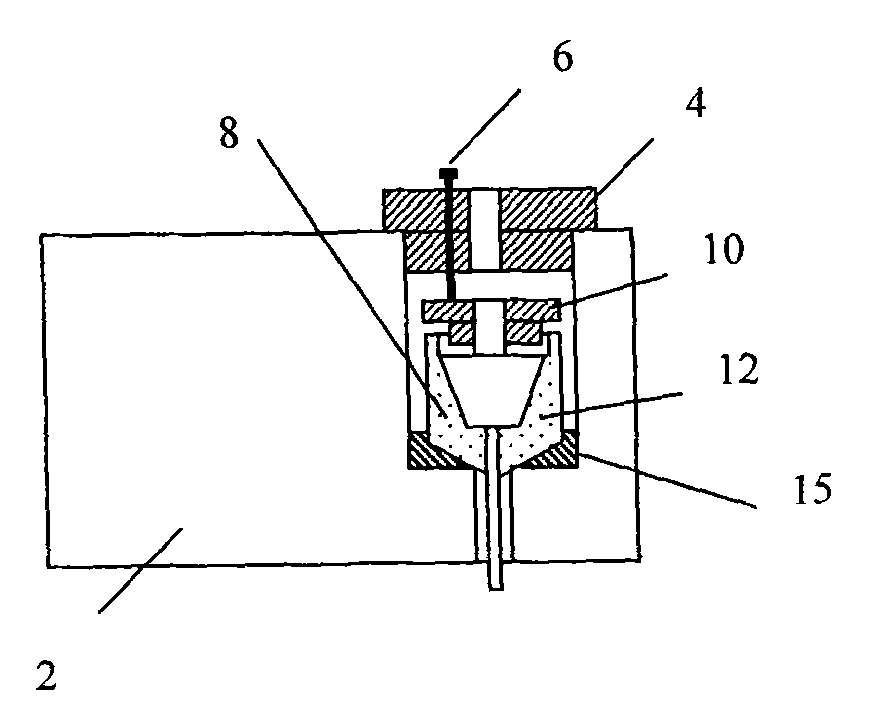

[0026] Such as figure 1 , 2 As shown, the porous spinning nozzle of the present invention is composed of a bottom sheet 1, a middle sheet 2, an upper cover 3, a fastening bolt 7, an insertion pipe fitting 8, and a positioning base 4.

[0027] One fastening bolt 7 connects the bottom sheet 1 and the middle sheet 2, and the other bolt connects the middle sheet 2 and the upper cover 3, thereby fixing the overall frame of the nozzle.

[0028] The fastening bolts 7 are evenly distributed on the circumference, and three are arranged. The bolts that connect the middle piece 2 and the loam cake 3 are equally distributed on the circumference three.

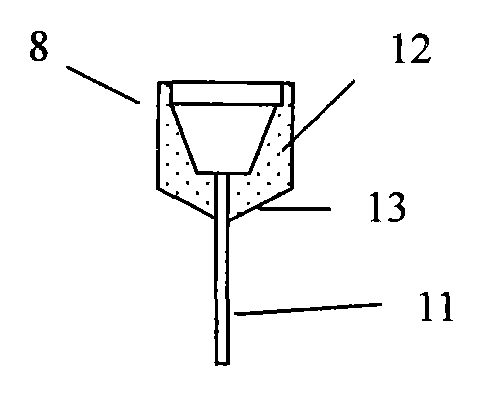

[0029] image 3 The structure of the insertion tube 8 of the present invention is shown in detail. Such as image 3 As shown, the insertion tube 8 has a socket 12 and an insertion tube 11 inserted in the socket. The tube base 12 constitutes the main body, its interior is hollow, and its shape is a cylinder, which is used to flow the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com