Polylactic acid toughening modifier and preparation method thereof

A technology of toughening modifier and polylactic acid, applied in the field of polylactic acid toughening modifier and its preparation, can solve the problems of too fast reaction, difficult operation, toxicity and the like, achieve good compatibility, save production cost, Low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 70 parts by mass of lactide and 30 parts by mass of PBS into the reaction flask, use toluene as solvent, add the catalyst stannous octoate accounting for 0.1% of the total mass of lactide and PBS, and raise the temperature to 150°C under nitrogen protection for 4.5 h. After the reaction is finished, the solvent is removed, and the product is purified and dried in vacuum.

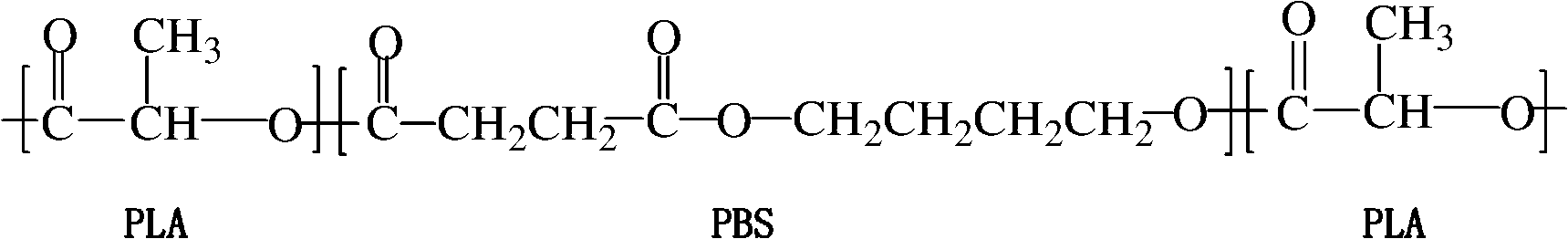

[0028] to the resulting polymer 1 H-NMR measurement confirmed its structure. The confirmation result is: on the basis that the PBS peak remains unchanged, a quartet appears at δ=5.15, and a double seal appears at δ=1.57. Corresponding to -CH in the PLA chain 3 and -CH peaks. The block copolymer of PBS and PLA was synthesized. according to 1 The molecular weight of the obtained block copolymer calculated by H-NMR is 158534.

[0029] At the same time, the obtained product was dissolved in chloroform to prepare a solution with a certain concentration, and its intrinsic viscosity at 26° C. was ...

Embodiment 2

[0031] Add 70 parts by mass of lactide and 30 parts by mass of PBS into the reaction flask, use toluene as solvent, add the catalyst stannous octoate accounting for 0.1% of the total mass of lactide and PBS, and raise the temperature to 170°C under nitrogen protection for 4.5 h. After the reaction is finished, the solvent is removed, and the product is purified and dried in vacuum.

[0032] to the resulting polymer 1 H-NMR measurement confirmed its structure. The confirmation result is: on the basis that the PBS peak remains unchanged, a quartet appears at δ=5.15, and a double seal appears at δ=1.57. Corresponding to -CH in the PLA chain 3 and -CH peaks. The block copolymer of PBS and PLA was synthesized. according to 1 The molecular weight of the obtained block copolymer calculated by H-NMR is 198449.

[0033] At the same time, the obtained product was dissolved in chloroform to prepare a solution with a certain concentration, and its intrinsic viscosity at 26° C. was ...

Embodiment 3

[0035] Add 90 parts by mass of lactide and 10 parts by mass of PBS into the reaction flask, use toluene as the solvent, add the catalyst stannous octoate accounting for 0.1% of the total mass of lactide and PBS, and heat up to 180°C under nitrogen protection for 6.5 h. After the reaction is finished, the solvent is removed, and the product is purified and dried in vacuum.

[0036] The obtained product was dissolved in chloroform to make a solution with a certain concentration, and its intrinsic viscosity at 26°C was measured with an Ubbelohde viscometer to be 0.49dL / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com