Process for soldering SiO2f/SiO2 composite ceramic and metal material

A technology of composite ceramics and metal materials, which is applied in the field of welding, can solve problems such as very large differences in thermal expansion coefficients, cracking of joints, lack of thermal stress, etc., and achieve the effect of reducing residual thermal stress and avoiding cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

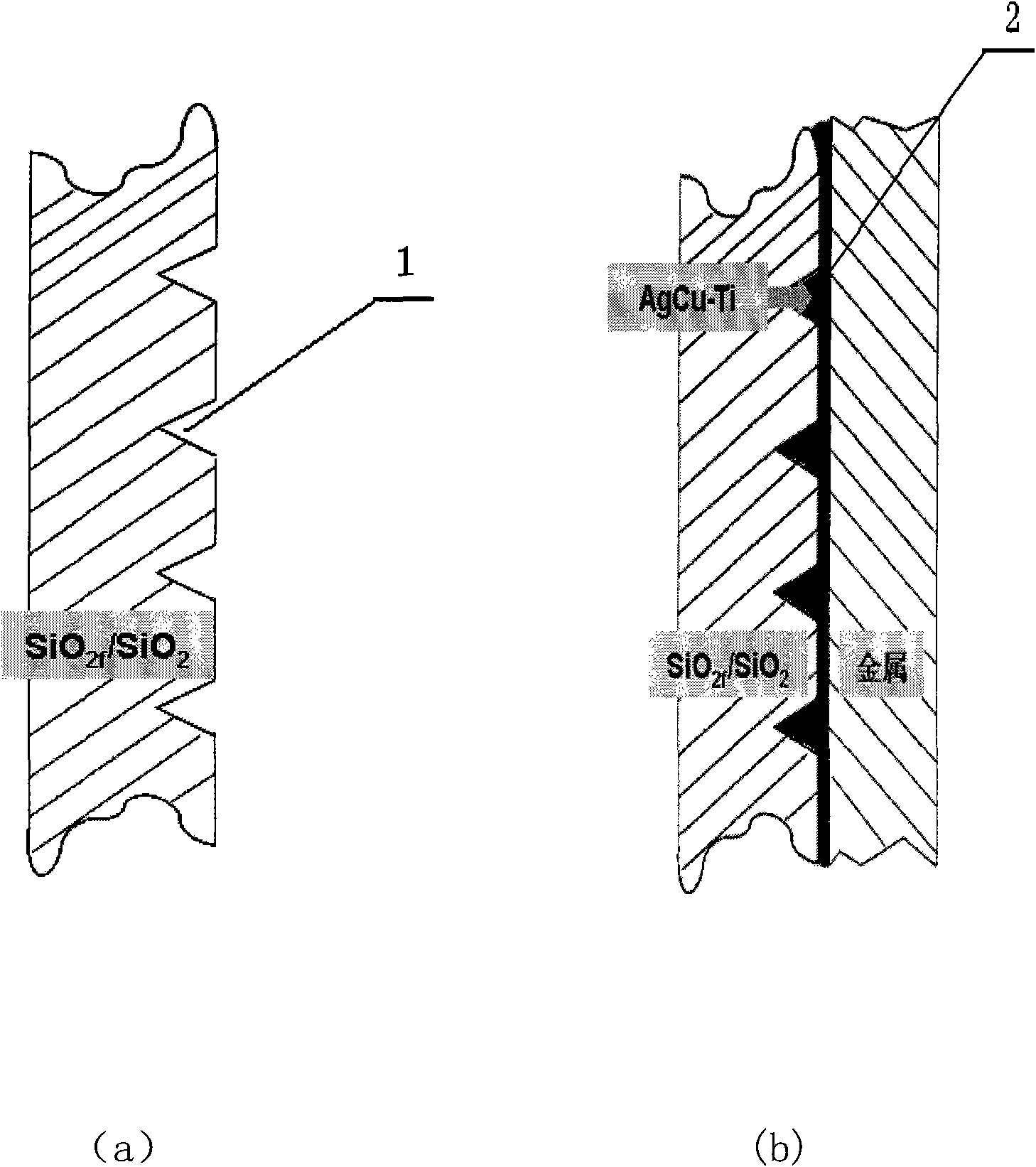

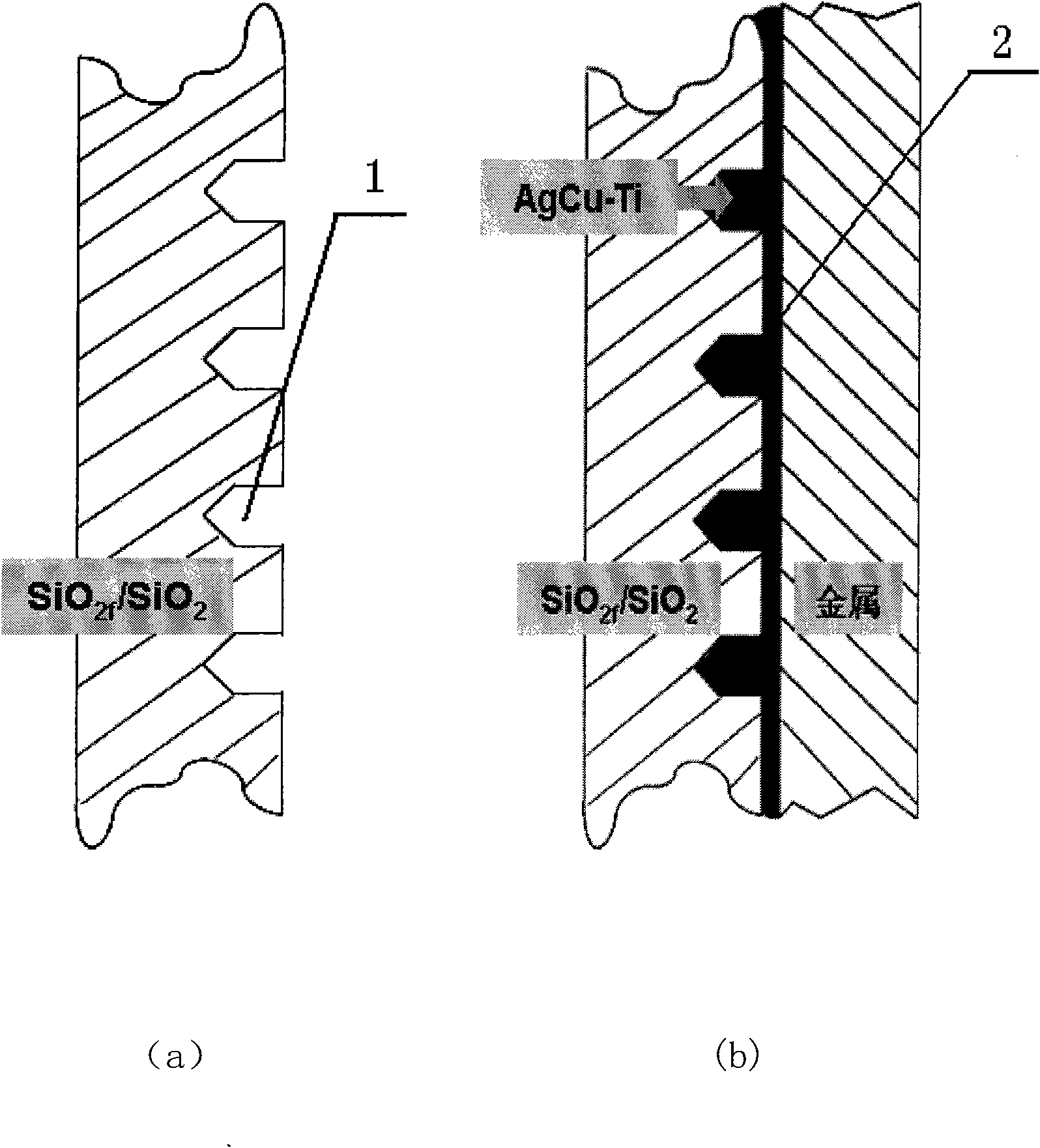

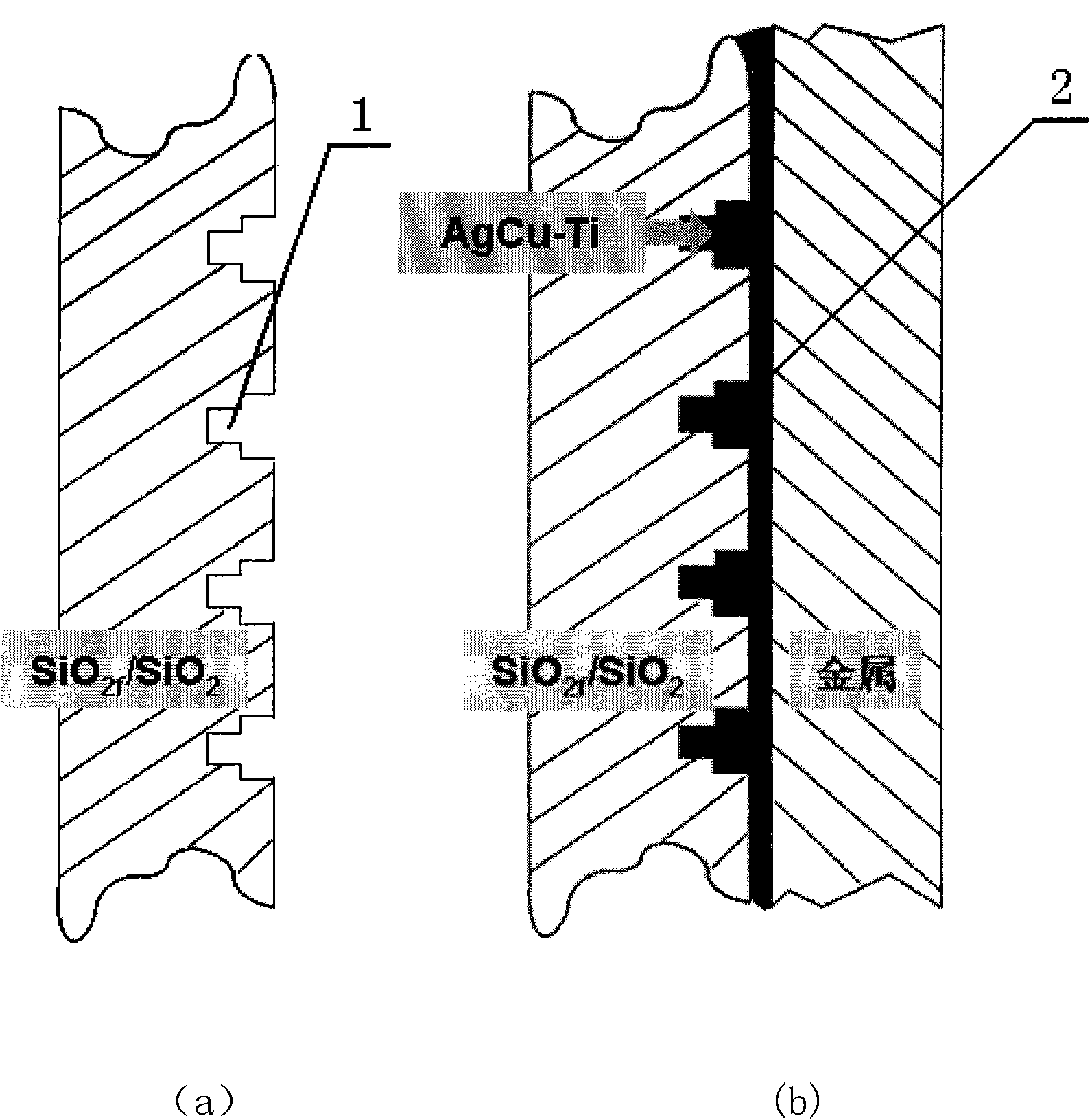

[0025] Respectively before welding by mechanical processing method on SiO 2f / SiO 2 The welded surface (plane) of the composite ceramics is grooved, and the grooves are parallel to each other, and the shape of the grooves corresponds to an approximate "V" groove (attached figure 1 ), approximately "U" shaped groove (attached figure 2 ), approximate "T" shaped slot (attached image 3 ), approximately straight groove (attached Figure 4 ). The surface width and depth of each groove are respectively 0.3mm-1.2mm and 1.0mm-3.5mm, and the interval between the grooves is 1.0mm-4.5mm.

[0026] Next, on SiO 2f / SiO 2 The groove on the surface of the composite ceramic to be welded and the welded SiO2 2f / SiO 2 The interface to be welded between composite ceramics and metal materials to be welded (4J36 alloy, TZM alloy, metal W, W alloy, metal Nb, Nb alloy, titanium alloy TC4, 18-8 stainless steel, GH783 alloy, 6H3044 alloy, GH4169 alloy) (Plane) are pre-prepared AgCu-Ti activ...

Embodiment 5

[0028] Before welding, the SiO 2f / SiO 2 The welded surface (annular surface) of the composite ceramics is grooved, and the grooves are distributed parallel to each other, and the shape of the grooves is an approximately straight groove (attached Figure 5 ). The surface width and depth of each groove are respectively 0.3mm-1.2mm and 1.0mm-3.5mm, and the interval between the grooves is 1.0mm-4.5mm.

[0029] Next, on SiO 2f / SiO 2 The groove on the surface of the composite ceramic to be welded and the welded SiO2 2f / SiO 2 The interface to be welded between composite ceramics and metal materials to be welded (4J36 alloy, TZM alloy, metal W, W alloy, metal Nb, Nb alloy, titanium alloy TC4, 18-8 stainless steel, GH783 alloy, GH3044 alloy, GH4169 alloy) (Annular surface) is pre-prepared AgCu-Ti active solder (Ti content between 1.4wt.% ~ 6.0wt.%), put it into a vacuum heating furnace together with the fixture after assembly, and heat it to 850 ° C ~ 910 ° C The brazing temp...

Embodiment 6

[0031] Respectively before welding by mechanical processing method on SiO 2f / SiO 2 The welded surface (plane) of the composite ceramics is grooved in two directions perpendicular to each other, and the grooves in the two directions are distributed parallel to each other, and the shape of each groove is an approximate "U" groove. The surface width and depth of each groove are 0.3mm-1.2mm and 1.0mm-3.5mm respectively, and the interval between the grooves is 1.0mm-4.5mm. Grooves are made in two directions perpendicular to each other, and all these grooves are distributed in a grid shape macroscopically. Next, on SiO 2f / SiO 2 The groove on the surface of the composite ceramic to be welded and the welded SiO2 2f / SiO 2 The interface to be welded between composite ceramics and metal materials to be welded (4J36 alloy, TZM alloy, metal W, W alloy, metal Nb, Nb alloy, titanium alloy TC4, 18-8 stainless steel, GH783 alloy, GH3044 alloy, GH4169 alloy) (Plane) are pre-prepared Ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com