Arc evaporation source actively controlling arc spot and equipment using same

An arc evaporation and active control technology, applied in vacuum evaporation plating, ion implantation plating, metal material coating process, etc. Number of particles, good adhesion and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

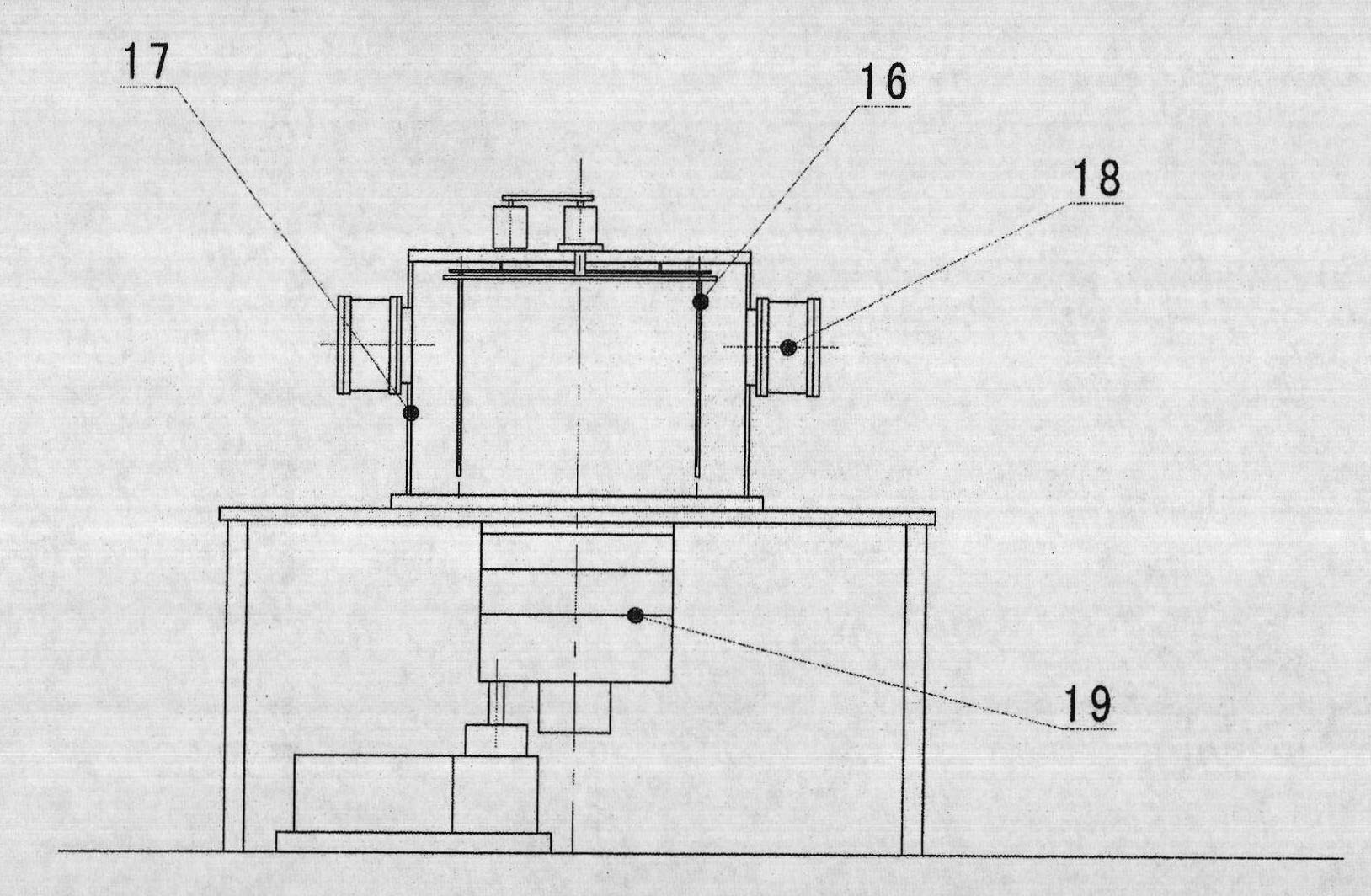

[0052] Embodiment 1: use the equipment of the present invention to plate titanium nitride coating on stainless steel mirror panel parts

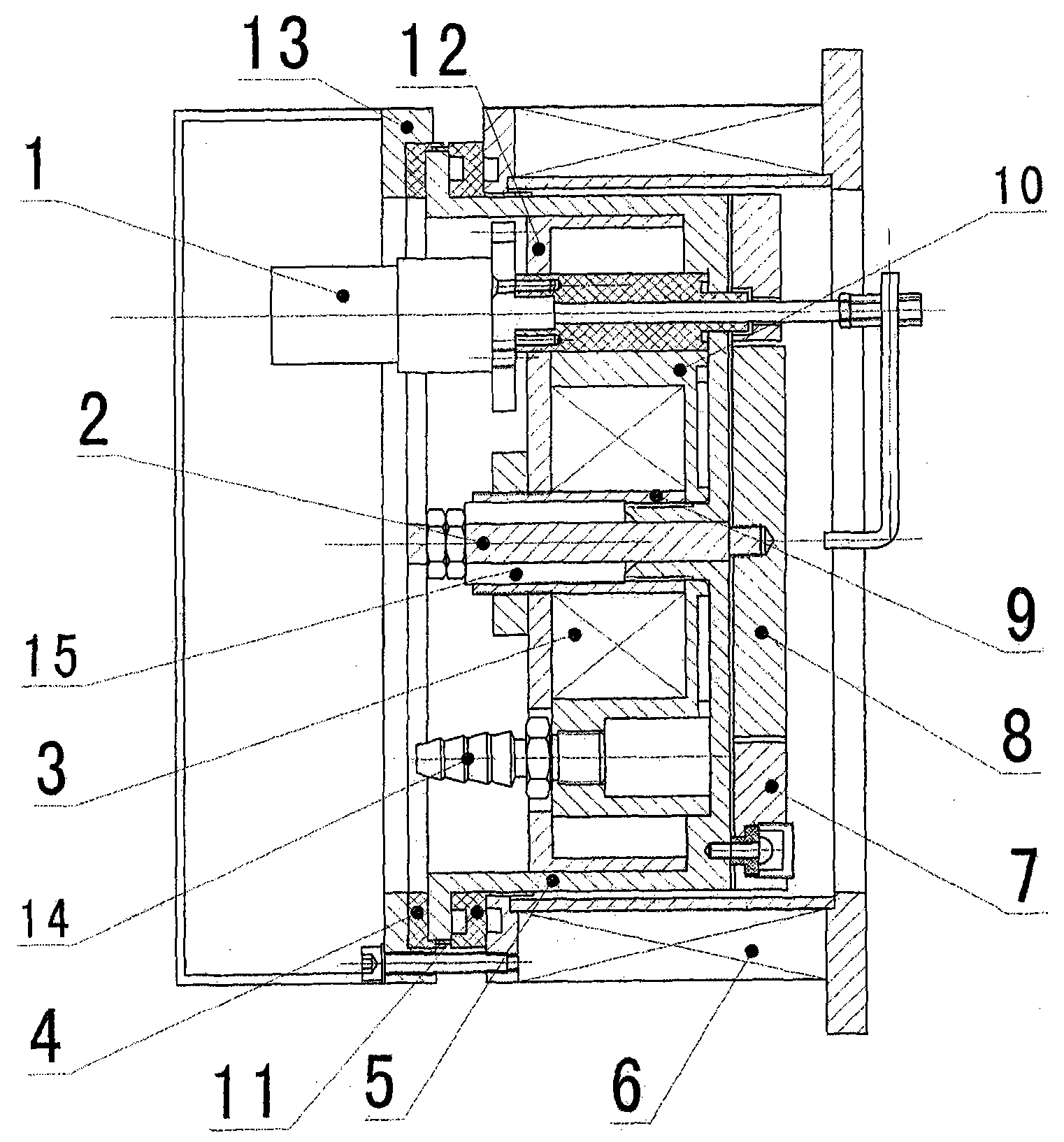

[0053] The inner cavity of the target base 5 is equipped with a water-cooled jacket 10 made of a magnetically conductive material (in this embodiment, when not specially marked, it is a non-magnetically conductive material), the water-cooled jacket 10 is fixed with the small magnetic field pole axis 9, and the target base 5 and A water-cooling cavity is formed between the water-cooling jackets 10, and a water outlet is arranged on the upper part of the water-cooling jacket 10, and a water inlet is arranged on the lower part. A small coil 3 is placed between the small magnetic field pole axis 9 and the water cooling jacket 10 . Place the small coil pole piece 12 made of magnetically conductive material outside the water cooling jacket 10, and tighten it with nuts, so that the small coil pole piece 12, the small magnetic field pole shaft 9, ...

Embodiment 2

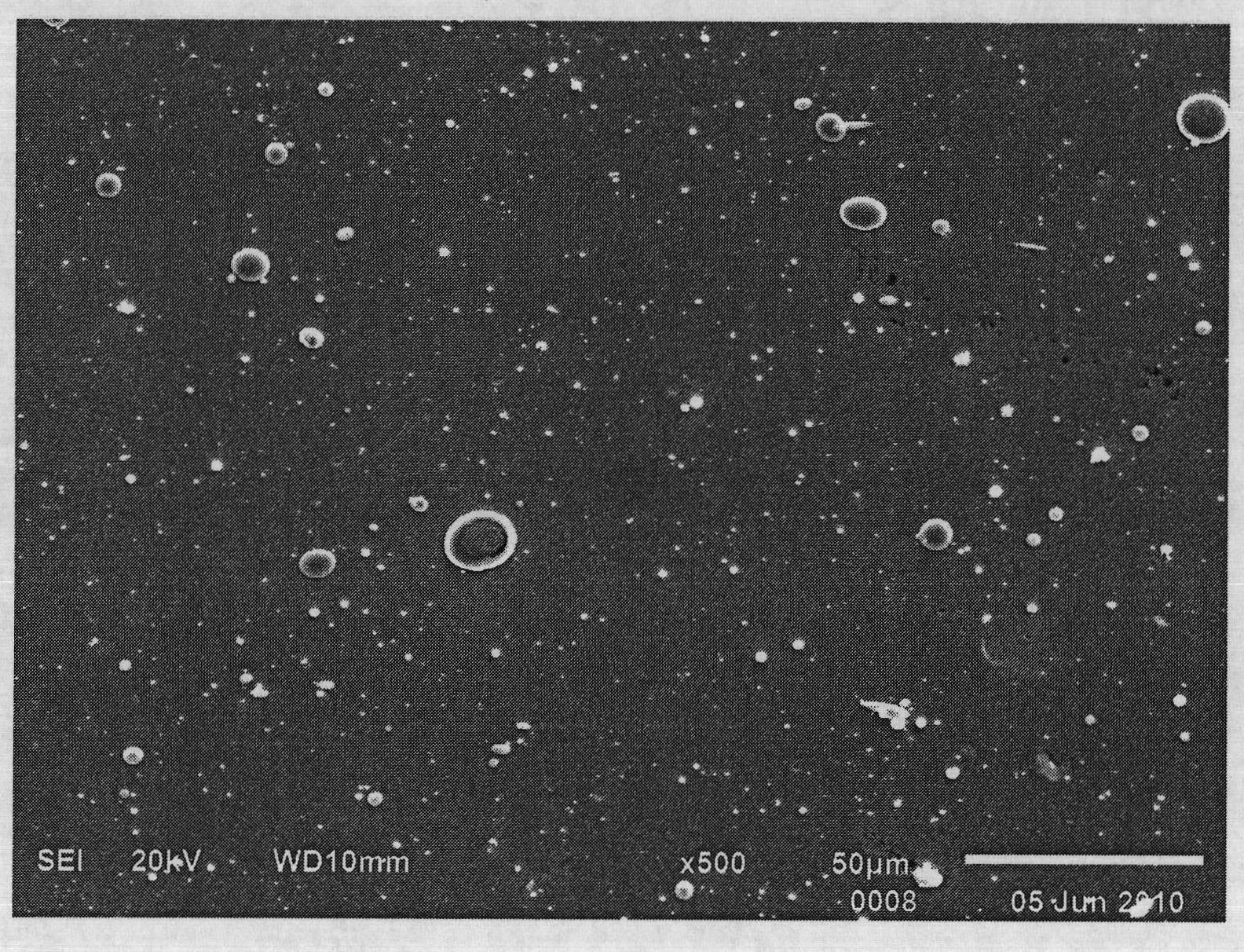

[0065] Embodiment 2: comparative test

[0066] Experimental equipment used to prepare the coating: the vacuum arc ion coating equipment of the present invention; the comparative test uses the ion coating equipment sold under the trade name TG-4 by Beijing Great Wall Titanium Co., Ltd. commonly used in the present technology.

[0067] The sample used in the test is a 304 stainless steel 8K mirror panel with a size of 20×20mm.

[0068] The sample coating (the sample of the present invention) was prepared by using the vacuum arc ion coating equipment of the present invention by the method described in Example 1 of the present invention.

[0069] The above-mentioned prior art ion coating equipment was used to prepare the sample coating (comparative sample) by the method described in the equipment manual.

[0070] The coating prepared by the method of the present invention and the prior art is titanium nitride.

[0071] Use the scanning electron microscope microscope to magnify...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com