Method for producing methanol by methane bioconversion

A technology of biotransformation and methane oxidizing bacteria, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., to achieve reliable technology, avoid unsafe hidden dangers, and strengthen the effect of gas-liquid mass transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

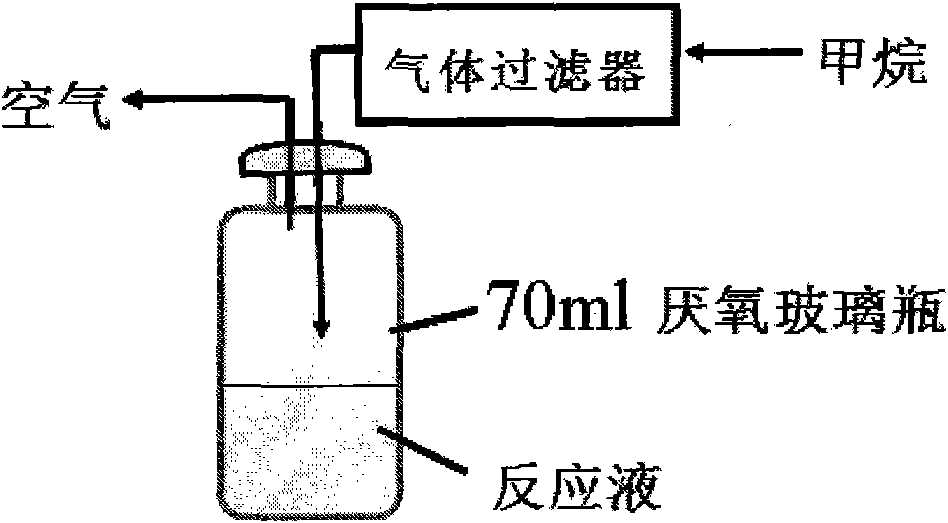

[0018] Embodiment 1, free cell transforms methane to produce methanol

[0019] In 70ml anaerobic glass bottle (see attached figure 1 ) into 10ml of reaction solution containing 0.4g stem cells / L methanotrophic bacterium Methylosinus trichosporium OB3b (purchased from the American Type Microorganism Collection, numbered ATCC 35070) free cells in the reaction solution, 60mmol / L Na 2 HPO 4 -NaH 2 PO 4 Solution (phosphate concentration is 120mmol / L, pH 7), 20mmol / L sodium formate and 5mmol / L MgCl 2 , airtight, extract 30ml of air, then inject 30ml of methane, 30°C, 170rpm shaker shaker reaction for 17h, to generate 12mmol / L methanol solution.

Embodiment 2

[0020] Embodiment 2, free cell transforms methane to produce methanol

[0021] In 70ml anaerobic glass bottle (see attached figure 1 ) was added with 10ml of reaction solution containing 10g of stem cells / L methanotrophic bacteria Methylosinus trichosporium OB3b (purchased from the American Type Microorganism Collection, numbered ATCC 35070) free cells in the reaction solution, 200mmol / L Na 2 HPO 4 -NaH 2 PO 4 solution (phosphate concentration is 400mmol / L, pH 6), 20mmol / L sodium formate and 5mmol / L MgCl 2 , airtight, extract 10ml of air, then inject 10ml of methane, 30°C, 120rpm shaker shaker reaction for 20h, to generate 13mmol / L methanol solution.

Embodiment 3

[0022] Embodiment 3, immobilized cell transforms methane to produce methanol

[0023] In 70ml anaerobic glass bottle (see attached figure 1 ) was added with 10ml of reaction solution containing 20g of stem cells / L of methanotrophic bacteria Methylosinus trichosporium OB3b (purchased from the American Type Microorganism Collection, numbered ATCC 35070) polyurethane immobilized cells in the reaction solution, 600mmol / L Na 2 HPO 4 -NaH 2 PO 4 solution (phosphate concentration is 1200mmol / L, pH 6), 20mmol / L sodium formate and 5mmol / L MgCl 2 , airtight, extract 30ml of air, then inject 30ml of methane, 30°C, 120rpm shaker shaker reaction for 24h to generate 30mmol / L methanol solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com